Fermentophile

Member

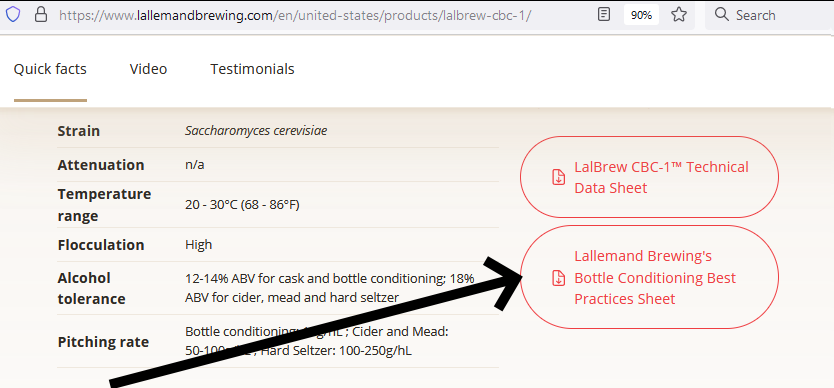

Hi all, I'm looking into brewing a super high gravity ale in the near future, something like Dogfish Head's World Wide Stout or 120 minute IPA. The alcohol lever will be 16-20% by the time it's done, and I would really prefer to bottle-condition the beer as I do with every other one I've made so far.

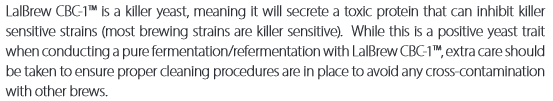

I see that in a lot of the recipes for WWS and 120 min IPA the beer is either force carbonated or it's left in carbonated. My question is, is there a way to try and carbonate a beer this big through bottle-conditioning? After a month or two in secondary and abusing the original yeast so much, will the yeast still he able to carbonate the beer if I just add priming sugar? I'm planning on using WLP099, pitching about a week in when i start feeding the fermenter with dextrose or wort. Ill be using well as another strain to start it off, don't know which one as I don't have a recipe mapped out yet...

Would it help to pitch a new starter if WLP099 before bottling? If so does anyone have any tips?

Appreciate the help! Thanks!

I see that in a lot of the recipes for WWS and 120 min IPA the beer is either force carbonated or it's left in carbonated. My question is, is there a way to try and carbonate a beer this big through bottle-conditioning? After a month or two in secondary and abusing the original yeast so much, will the yeast still he able to carbonate the beer if I just add priming sugar? I'm planning on using WLP099, pitching about a week in when i start feeding the fermenter with dextrose or wort. Ill be using well as another strain to start it off, don't know which one as I don't have a recipe mapped out yet...

Would it help to pitch a new starter if WLP099 before bottling? If so does anyone have any tips?

Appreciate the help! Thanks!