Figured I had some time to post some of my major project that has been dragging over the late fall/winter and continues to be a work in progress.

I am essentially doing this build as I get time and $$$ to work on it.

Water/Sink:

I did not put in a sink or a water supply to this building as location and water supply lines prevented this from being cost effective to put in. I will be using a cooler with a pond pump and a DudaDiesel plate chiller to recirculate the cold water/wort for chilling along with 5 gallon jugs of Primo RO store bought water for my brew water supply so I did without a water supply in this building. It sucks, but sacrifices had to be made.

Building:

This involved a 12x24 custom brew shed that I had the underfloor insulated to keep condensation from bowing the floor in, and a full back window put in for a window AC/Heat unit in. I build a pad out of crushed gravel for the building to sit on to keep proper drainage and reduce the bug factor..

I wired the shed with 50amp 240v service , breaker panel with about 6 circuits, outlets for lights, etc, along with the needed 240v 30amp outlet for my Kal panel.

Panel:

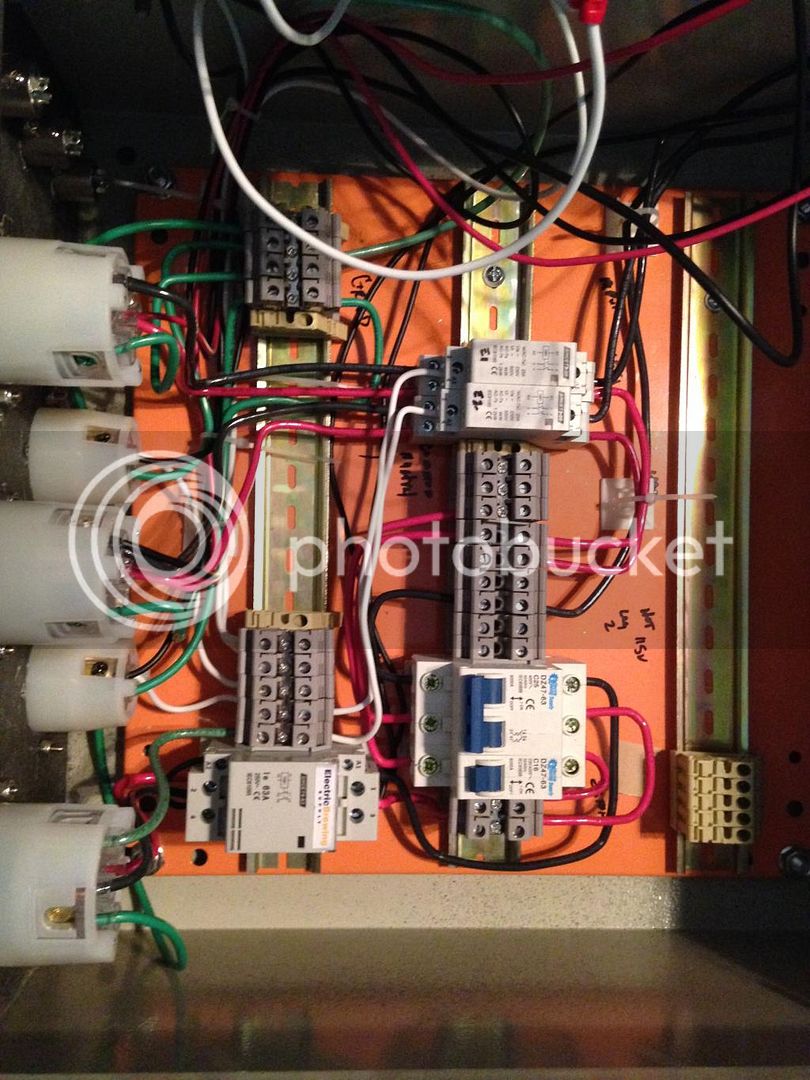

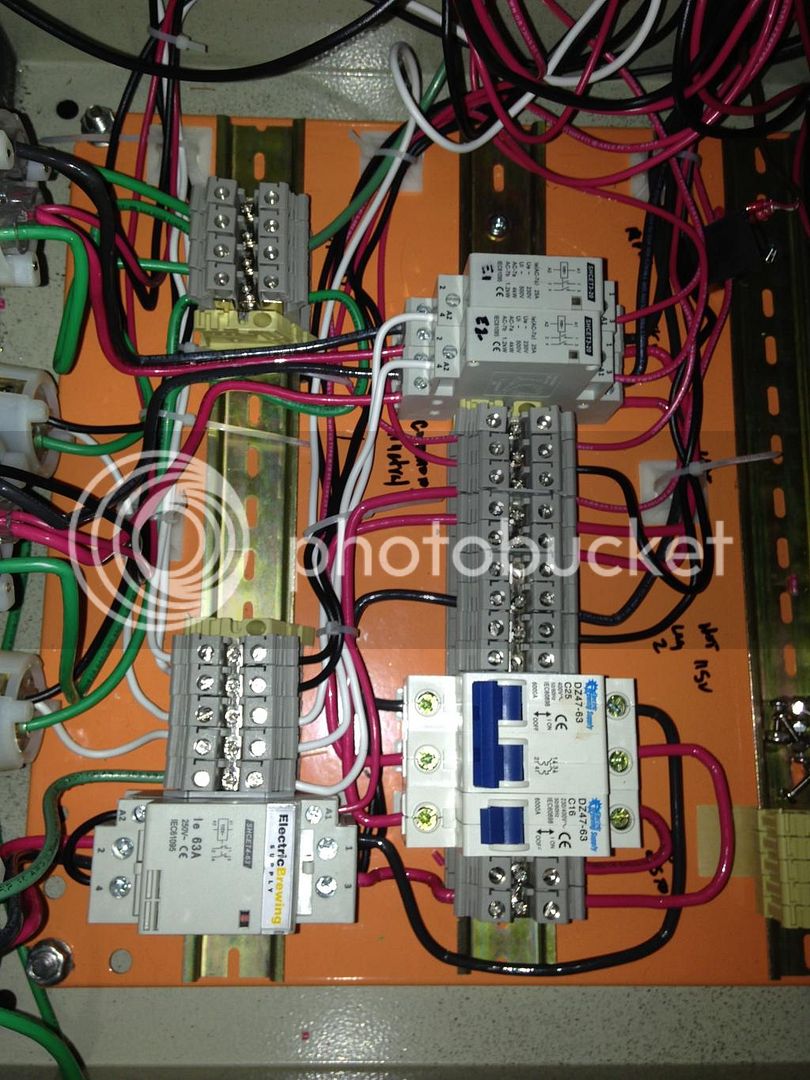

I used a ebrewsupply 2 PID - 30amp kit for this along with the panel box and heat sink combo from Auberins. The top was predrilled for the heat sink so this made life easy for this part of the panel. I used 3 Auberin PIDS with a Auberin timer. I also put in the ebrewsupply Amp and voltage meters. They look good.

I also used DIN rail contactors for ease of installation. Wiring tidyness sucks, but I am after functionality, not aesthetics with the wiring. I know I can fix it if it breaks and honestly, how many times am I really going to be opening the panel. I purchased kals temp probe kits and had one of my soldering buddies at work make them for me for some free beer. They look great. Panel powers up and so far everything looks to work. True test will come once the building is done and bench/pots are in place and plugged in.

Pots:

I picked up 2 of the 2-weld AIH SS brew pots($119ea) 15-gallon pots for MT and HLT and repurposed my Keggle for a brewpot.

All hardware came from BFittings or Ebay. I have some extra hardware so I plan on putting them up for sale once I get everything completed.

Pumps/Hoses:

Also have 2 chugger pumps, and have built out the needed quick disconnect silicone hoses. I used the same disconnects as Kal.

SS HERMS Coil:

This came from stainlessfittings.com. I went with the 50ft, 10" coil. It sits a little tall in the 15 gallon HLT, but will work great!

Ventilation:

I built my own. This was essentially a bunch of 2x4s I made for the box along with some slats for the top. Used mending components to hold it all together with some screws, drilled a 6" hold in the top, and mounted the inline blower motor to the top of the box. Total cost, $40 for the box, $70 for the motor. The drywall ceiling when it goes in will have a trapdoor to allow me to service the motor should it need it. I also going to plug the motor into a variable speed controller to allow my to easily control motor speed. Tested the setup once it was mounted to the wall by burning a cardboard box and it performed well pulling all the smoke out even with the box burning at a level well below where the brew pots will be.

To-Dos:

1. Finish the drywall ceiling/mudding/sanding/painting. DONE 3/21

2. Put the flooring in(using cheap snap together laminate for the flooring). DONE 3/29

3. Finish the front building stairs/skirting(landscaping) - TBD 4/4

4. Put a sheet of acrylic sheeting up as a backsplash. - DONE 3/16

5. Build the brew bench(Kal wood build planned) - DONE 3/16

6. Finish the element wiring(power cords) TBD Week of 4/4

7. Finish the last fittings for the HLT water intake(Top)

8. Mount the pumps to brew bench. TBD 4/5

9. Mount panel and plug it all in with pots in place. TBD 4/5

10. Fill it all up with water and run auto-tune process TBD 4/5

11. Dial it all in and do a test run with just water to bring everything up to temp and simulate a brew day. TBD 4/5

12. Brew!

Outside of building:

Drywall work in progress:

Wall where brew bench is going pre-vent hood install/drywall:

Vent hood built and sitting on floor:

Vent hood mounted:

Crappy pic of the underside of the hood where the vent hole is(I will be lining the inside of this box with white acrylic):

Pic of the motor on the top of vent hood:

Photo of brew wall with vent hood mounted and wall drywalled. Outside of vent hood will eventually also be drywalled to look like part of the original structure:

Outside of building showing the duct exhaust I installed(I used a HD exhaust..No plastic here!):

Brew Panel Pics in planning stages and post build:

Pics of wiring in various stages of build:

Virgin Pots:

Fitting Candy:

Pots build-out:

Lessons learned so far:

- Buy your SS grooved nuts from BFittings or from Bobby. DO NOT BUY THESE ON EBAY! The ones I got were total crap and would not seat fully down on the NPT nipples. They were also about 1/8" thicker than the ones you get from BFittings or from Bobby.

- Buy Greenlee punchouts. I bought the QMax punches from Amazon and a month and half later, they have not shown up. Working through getting a refund and ended up buying Greenlees to keep my project moving. I will be selling these here once this build is wrapped up.

- Use the yellow thread tape and wrap up your fittings properly. This is critical to getting a no leak weldless seal the first time!! Kal mentions this and its very important you wrap the right direction and wrap enough times to get the proper seal. I put my nuts on the inside of the pot. Kal has his on the outside. its 6 one way half a dozen the other to be honest. Just get them to not leak and you are all set.

- Buy the SS HERMS coil pre-fabbed...seriously. You will save not only your time, but lots of frustration buy just buying this pre-made from Stainlessfittings.com. Very happy with mine and the cost is in line with buying the SS and forming myself.

- Glad I planned to do this over a long period of time. I knew this would be a long project going in, and knowing this has kept my patience and wallet in check.

- I LOVE LOVE LOVE the AIH SS 15 gallon 2 weld pots. for $119 each, I cannot stress enough how great of a deal these pots are. The lids are crappy, but the pots are top notch.

- EBrewsupply has been rock solid in all my build. I have had to ping them more than once and they have stepped up and replied timely and even tossed in a few freebies that I did not ask for. TOP NOTCH outfit. I even bought my DIY Element Kits and one of my chuggers through them. Cannot recommend them highly enough for those wanting a solid kit to do your build.

- For those who are scared of doing this wiring-wise, or DIY-wise, don't be. If I can do this, anyone can. Just plan your build right, don't rush it and take your time. These types of builds take time and money. Most of us dont have much of either of these so plan, plan, plan.

Ballpark cost(rough approx of what I remember paying for each of these):

- 12x24 building with insulated floor and extra full rear window(vinyl siding) - $6k

- Building build-out, wiring, drywall, etc - $800

- Lowe's Select Tavern Oak Flooring - 10 boxes @ 21.50 box = $215

- Lowe's Paint - Leftover paint from living room renovation - Free

- Pumps(1 center inlet SS, 1 inline Poly) - $260

- Pots, fittings, HERMS coil and element kits - $700(I already had the keggle on hand)

- Panel kit, enclosure, wiring - $700

- Vent Hood(inc motor and ducting/exhaust) - $200

- AC/Heat window unit - $400

- Brew Bench(wood, bolts, finish) - $80

I will post more as this build progresses, but wanted to at least get my own e-brew shed build started here for others to see/comment on.

I am essentially doing this build as I get time and $$$ to work on it.

Water/Sink:

I did not put in a sink or a water supply to this building as location and water supply lines prevented this from being cost effective to put in. I will be using a cooler with a pond pump and a DudaDiesel plate chiller to recirculate the cold water/wort for chilling along with 5 gallon jugs of Primo RO store bought water for my brew water supply so I did without a water supply in this building. It sucks, but sacrifices had to be made.

Building:

This involved a 12x24 custom brew shed that I had the underfloor insulated to keep condensation from bowing the floor in, and a full back window put in for a window AC/Heat unit in. I build a pad out of crushed gravel for the building to sit on to keep proper drainage and reduce the bug factor..

I wired the shed with 50amp 240v service , breaker panel with about 6 circuits, outlets for lights, etc, along with the needed 240v 30amp outlet for my Kal panel.

Panel:

I used a ebrewsupply 2 PID - 30amp kit for this along with the panel box and heat sink combo from Auberins. The top was predrilled for the heat sink so this made life easy for this part of the panel. I used 3 Auberin PIDS with a Auberin timer. I also put in the ebrewsupply Amp and voltage meters. They look good.

I also used DIN rail contactors for ease of installation. Wiring tidyness sucks, but I am after functionality, not aesthetics with the wiring. I know I can fix it if it breaks and honestly, how many times am I really going to be opening the panel. I purchased kals temp probe kits and had one of my soldering buddies at work make them for me for some free beer. They look great. Panel powers up and so far everything looks to work. True test will come once the building is done and bench/pots are in place and plugged in.

Pots:

I picked up 2 of the 2-weld AIH SS brew pots($119ea) 15-gallon pots for MT and HLT and repurposed my Keggle for a brewpot.

All hardware came from BFittings or Ebay. I have some extra hardware so I plan on putting them up for sale once I get everything completed.

Pumps/Hoses:

Also have 2 chugger pumps, and have built out the needed quick disconnect silicone hoses. I used the same disconnects as Kal.

SS HERMS Coil:

This came from stainlessfittings.com. I went with the 50ft, 10" coil. It sits a little tall in the 15 gallon HLT, but will work great!

Ventilation:

I built my own. This was essentially a bunch of 2x4s I made for the box along with some slats for the top. Used mending components to hold it all together with some screws, drilled a 6" hold in the top, and mounted the inline blower motor to the top of the box. Total cost, $40 for the box, $70 for the motor. The drywall ceiling when it goes in will have a trapdoor to allow me to service the motor should it need it. I also going to plug the motor into a variable speed controller to allow my to easily control motor speed. Tested the setup once it was mounted to the wall by burning a cardboard box and it performed well pulling all the smoke out even with the box burning at a level well below where the brew pots will be.

To-Dos:

1. Finish the drywall ceiling/mudding/sanding/painting. DONE 3/21

2. Put the flooring in(using cheap snap together laminate for the flooring). DONE 3/29

3. Finish the front building stairs/skirting(landscaping) - TBD 4/4

4. Put a sheet of acrylic sheeting up as a backsplash. - DONE 3/16

5. Build the brew bench(Kal wood build planned) - DONE 3/16

6. Finish the element wiring(power cords) TBD Week of 4/4

7. Finish the last fittings for the HLT water intake(Top)

8. Mount the pumps to brew bench. TBD 4/5

9. Mount panel and plug it all in with pots in place. TBD 4/5

10. Fill it all up with water and run auto-tune process TBD 4/5

11. Dial it all in and do a test run with just water to bring everything up to temp and simulate a brew day. TBD 4/5

12. Brew!

Outside of building:

Drywall work in progress:

Wall where brew bench is going pre-vent hood install/drywall:

Vent hood built and sitting on floor:

Vent hood mounted:

Crappy pic of the underside of the hood where the vent hole is(I will be lining the inside of this box with white acrylic):

Pic of the motor on the top of vent hood:

Photo of brew wall with vent hood mounted and wall drywalled. Outside of vent hood will eventually also be drywalled to look like part of the original structure:

Outside of building showing the duct exhaust I installed(I used a HD exhaust..No plastic here!):

Brew Panel Pics in planning stages and post build:

Pics of wiring in various stages of build:

Virgin Pots:

Fitting Candy:

Pots build-out:

Lessons learned so far:

- Buy your SS grooved nuts from BFittings or from Bobby. DO NOT BUY THESE ON EBAY! The ones I got were total crap and would not seat fully down on the NPT nipples. They were also about 1/8" thicker than the ones you get from BFittings or from Bobby.

- Buy Greenlee punchouts. I bought the QMax punches from Amazon and a month and half later, they have not shown up. Working through getting a refund and ended up buying Greenlees to keep my project moving. I will be selling these here once this build is wrapped up.

- Use the yellow thread tape and wrap up your fittings properly. This is critical to getting a no leak weldless seal the first time!! Kal mentions this and its very important you wrap the right direction and wrap enough times to get the proper seal. I put my nuts on the inside of the pot. Kal has his on the outside. its 6 one way half a dozen the other to be honest. Just get them to not leak and you are all set.

- Buy the SS HERMS coil pre-fabbed...seriously. You will save not only your time, but lots of frustration buy just buying this pre-made from Stainlessfittings.com. Very happy with mine and the cost is in line with buying the SS and forming myself.

- Glad I planned to do this over a long period of time. I knew this would be a long project going in, and knowing this has kept my patience and wallet in check.

- I LOVE LOVE LOVE the AIH SS 15 gallon 2 weld pots. for $119 each, I cannot stress enough how great of a deal these pots are. The lids are crappy, but the pots are top notch.

- EBrewsupply has been rock solid in all my build. I have had to ping them more than once and they have stepped up and replied timely and even tossed in a few freebies that I did not ask for. TOP NOTCH outfit. I even bought my DIY Element Kits and one of my chuggers through them. Cannot recommend them highly enough for those wanting a solid kit to do your build.

- For those who are scared of doing this wiring-wise, or DIY-wise, don't be. If I can do this, anyone can. Just plan your build right, don't rush it and take your time. These types of builds take time and money. Most of us dont have much of either of these so plan, plan, plan.

Ballpark cost(rough approx of what I remember paying for each of these):

- 12x24 building with insulated floor and extra full rear window(vinyl siding) - $6k

- Building build-out, wiring, drywall, etc - $800

- Lowe's Select Tavern Oak Flooring - 10 boxes @ 21.50 box = $215

- Lowe's Paint - Leftover paint from living room renovation - Free

- Pumps(1 center inlet SS, 1 inline Poly) - $260

- Pots, fittings, HERMS coil and element kits - $700(I already had the keggle on hand)

- Panel kit, enclosure, wiring - $700

- Vent Hood(inc motor and ducting/exhaust) - $200

- AC/Heat window unit - $400

- Brew Bench(wood, bolts, finish) - $80

I will post more as this build progresses, but wanted to at least get my own e-brew shed build started here for others to see/comment on.