We're getting a new furnace and AC unit on Saturday. The guy who is doing the install is a longtime friend, runs a very successful company doing HVAC, and assured me his guys can install a splice with a quick connect into the natural gas line to the furnace so I can run a line to my brewstand, and finally stop running to the corner store for propane every couple of weeks. I know I need to change out the orifices on the burners, and buy the line to run from the gas pipe to the burners. The hose I'm going to get is 10 feet long so that isn't an issue. Just wanted to know if anyone else had done the same, and what issues you ran into during install/running the burners? Needle or ball valves to control gas flow? Any tips/tricks to make it easier?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone converted burners from propane to natural gas?

- Thread starter seatazzz

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ITV

Well-Known Member

I had my licensed plumber son hook up a natural gas line in my garage and later on in my basement kitchen. He ran a main line for both instead of splicing into to an existing gas appliance line.

I had no issues, I recommend that a ball lock shut off valve be installed before the quick connect and that you have good ventilation. I had to re-adjust the damper valve when converting between propane and NG.

I had no issues, I recommend that a ball lock shut off valve be installed before the quick connect and that you have good ventilation. I had to re-adjust the damper valve when converting between propane and NG.

There's a dependency on burner type wrt an optimal configuration. An up-stream ball valve is always handy as a binary shutoff, while something like the Williams Brewing needle valve for running a bg14 on NG would work nicely for modulating burner power. But I don't know if there's a solution for any random burner type - bg12 and bg10 elements don't seem to work well on NG...

Cheers!

Cheers!

ITV

Well-Known Member

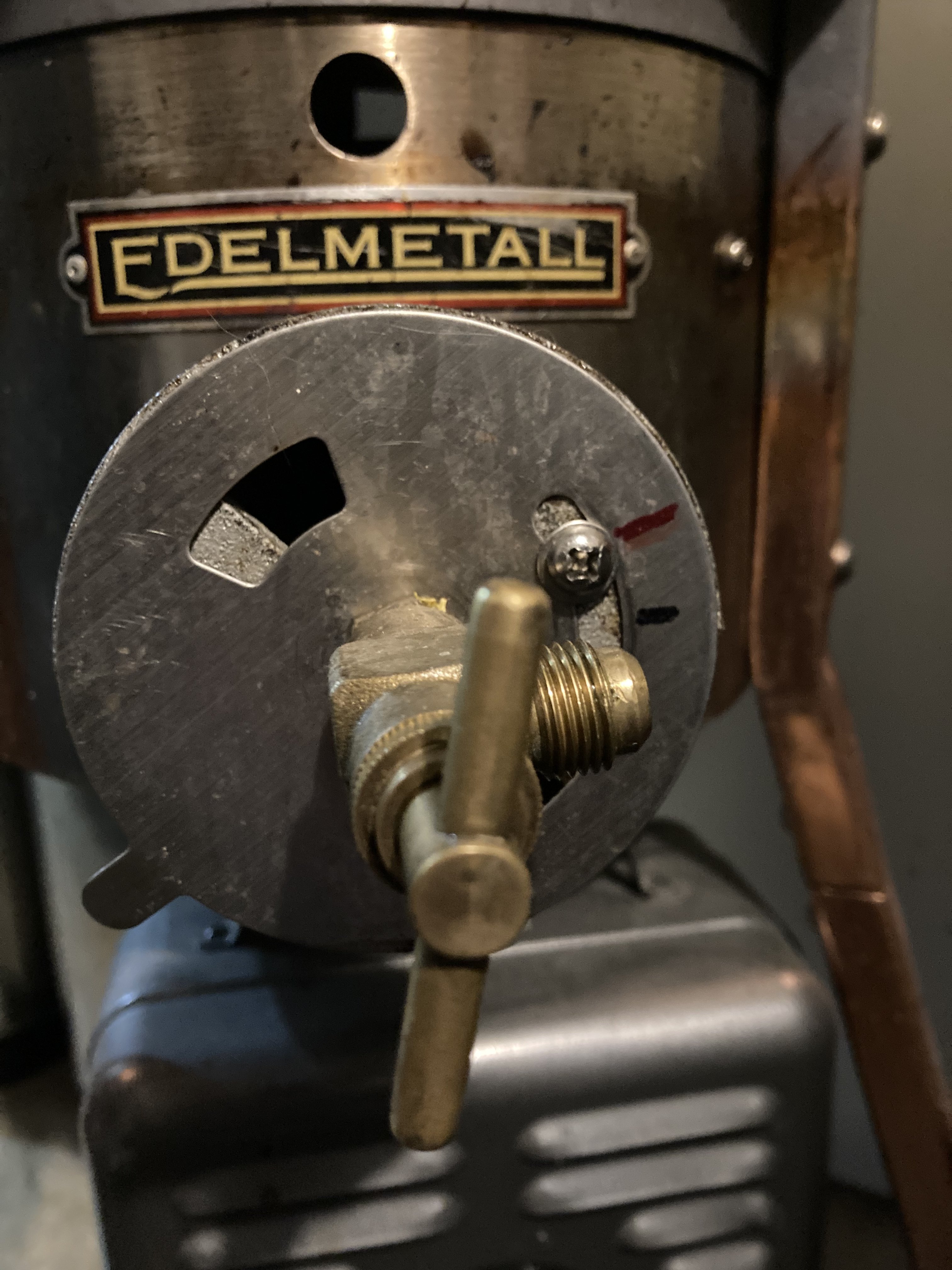

I should clarify I am using the Edelmetall burner and I use it to heat strike water and boil only. The needle valve that comes with the burner works great.

I do have a NG ball valve that I bought way back in the day thinking it would work on my brewstand (it didn't, for obvious reasons, that I was trying to use it with propane). I'll ask the guys to install it before the quick connect, shouldn't be an issue. I always have the door to the house open, and the garage door cracked, when brewing so ventilation isn't an issue either. By damper valve, do you mean the round thing (pardon my lack of technical lingo!) on the burner that controls the flame?I had my licensed plumber son hook up a natural gas line in my garage and later on in my basement kitchen. He ran a main line for both instead of splicing into to an existing gas appliance line.

I had no issues, I recommend that a ball lock shut off valve be installed before the quick connect and that you have good ventilation. I had to re-adjust the damper valve when converting between propane and NG.

Can you clarify what bg10, 12, 14 are?There's a dependency on burner type wrt an optimal configuration. An up-stream ball valve is always handy as a binary shutoff, while something like the Williams Brewing needle valve for running a bg14 on NG would work nicely for modulating burner power. But I don't know if there's a solution for any random burner type - bg12 and bg10 elements don't seem to work well on NG...

Cheers!

ITV

Well-Known Member

Correct, it adjusts the air/gas mixture.By damper valve, do you mean the round thing (pardon my lack of technical lingo!) on the burner that controls the flame?

ITV

Well-Known Member

Correct, it adjusts the air/gas mixture.

It’s the silver disk with slots.

ITV

Well-Known Member

Can you clarify what bg10, 12, 14 are?

Sure! They are all Bayou Classic burner elements.

Bg10:

Bg12:

Bg14:

Afaik, only the "big banjo" bg14 burner works acceptably well on NG with the appropriate orifice...

Cheers!

Thanks for the clarification! My burners are apparently BG12. I'm not quite ready to upgrade so I will see what I can make work with them. If they don't work, I guess I'll have to spend the $$ to get bigger ones, dammit.

Depending on the regulator you have for the burner, it may be an issue. NG is supplied at 11" WC which is 0.397400210100894 psi. The orfice should be sized for NG. Many Propane regulators are high pressure.

LOL, my GOD! what are you brewing, 50 gallon batches! i manage to boil 15 gallons on my kitchen stove! that thing looks like a beast!Afaik, only the "big banjo" bg14 burner works acceptably well on NG with the appropriate orifice...

edit: for some reason this is always what i think of, when i think BIG NG burners...

https://www.actionsales.com/en/wok-...sB8n7C1iWECTPcm66jE6Uv1OtwaUpgS8aAqp7EALw_wcB

The bg14 is 10" in diameter and with a 10 psi regulator produces around 75k btu. I brew 10 gallon batches on a 3v2p single tier herms with three 20 gallon Blichmann G1 kettles. Actually a very nicely balanced rig...

Cheers!

Cheers!

The bg14 is 10" in diameter and with a 10 psi regulator produces around 75k btu. I brew 10 gallon batches on a 3v2p single tier herms with three 20 gallon Blichmann G1 kettles. Actually a very nicely balanced rig...

Cheers!

i brew over two 3" burners, that i helped out a bit with a pairing knife..... i can get a pretty vigorous boil...10 gallon batches also.

Thoughts and prayers...

Cheers!

Cheers!

Thoughts and prayers...

Cheers!

had a close one tuesday....added the pellet hops strait to the boil for a change, boiled over and knocked both the burners out..thankfully i didn't have some contraption to drop them in automatically!

emptygrowler

New Member

- Joined

- Aug 26, 2020

- Messages

- 3

- Reaction score

- 4

As for the orifaces, I just drilled mine out. i do forget what size but I googled it. Since NG is so low pressure, you need more of it so the larger hole fixes that. The air/gas mixture ring did need adjusting. I have been on NG for years now. I had a ball valve on the hardline in the house and a quick connect for hooking it up. If you need pics, ask me and I will attach some. Brewing tomorrow!

Climb

Well-Known Member

Here is another option for you to consider before you drill out your existing propane burners. I built my brew stand, plumbed for NG, using burners and thermostats from conventional tank water heaters. They are easy to find for free on Craig's List due to the hard water we have in SoCal. Since the picture, I have installed a ball valve before each water heater thermostat. I use the ball valve to throttle the NG to the burner. I use the water heater thermostats primarily for their pilot lights and On/Off control while keeping the pilot light on. The black gas pipe is 1" and I found some inexpensive vinal tubing at HD to run from my gas main to the 1" black pipe on the brew stand. FYI, no way does this meet any building code, but I only have this connected while I am brewing.

Attachments

Here's what my HVAC guy installed in the NG line. He took a look at my burners and agreed that larger orifices (cheap at HD) should be all I need to change out, plus buying the line to go from the NG to the burners. I'm going with quick connects as well since I have two burners and use both during a brewday. They are on order and won't be here until Tuesday, so tomorrow is my absolute last day on propane (except when I take the brewery on the road). Cannot WAIT.

![20210717_183216[1].jpg 20210717_183216[1].jpg](https://cdn.homebrewtalk.com/data/attach/676/676592-20210717-183216-1-.jpg)

![20210717_183216[1].jpg 20210717_183216[1].jpg](https://cdn.homebrewtalk.com/data/attach/676/676592-20210717-183216-1-.jpg)

Wanted to update this for anyone interested. Got the hose and adapter yesterday, and today a quick trip to HD got the rest of the hardware needed. After carefully connecting everything, with much soapy water sprayed to put the kibosh on any leaks, we are (almost) fully natural gas now. Just need the second hose and adapter to show up Thursday (forgot to push the button on it yesterday) and we are good to go. 4 gallons of dead cold water heated up from 75 to 163 in ten minutes; yes a bit less than the old propane setup, but I am perfectly willing to sacrifice some time in a brewday to avoid the endless propane tank exchange.

For anyone searching/researching/thinking about this, I will note here that blue monster tape works as well or better than yellow gas tape. And MAKE SURE you don't ramp down too hard when connecting to avoid cracking. Brass (especially cheap crap from China) has a tendency to crack and leak. Plenty of joint tape, and being careful to stop when it doesn't want to go any more, will see you good. I will also note that having a certified plumber/HVAC person install your connection to NG is imperative. I don't want anyone to blow up their house/family/pets/friends.

For anyone searching/researching/thinking about this, I will note here that blue monster tape works as well or better than yellow gas tape. And MAKE SURE you don't ramp down too hard when connecting to avoid cracking. Brass (especially cheap crap from China) has a tendency to crack and leak. Plenty of joint tape, and being careful to stop when it doesn't want to go any more, will see you good. I will also note that having a certified plumber/HVAC person install your connection to NG is imperative. I don't want anyone to blow up their house/family/pets/friends.

Once again, an update. Ran another test on the HLT last night, after having drilled out the orifice to 5/64. Took forever to get up to strike temperature, and could not achieve a boil. This morning I said the heck with it, took it apart, and increased the orifice hole to 7/64. After putting it back together (once again thoroughly checking for leaks with soapy water), the flame is MUCH higher, just as high as it was with propane, and 8 gallons of water went from 88° to boiling in 30 minutes! Flame is blue all the way up, and a quick peek at the bottom of the keggle shows no soot, so the burn was quite efficient. YMMV, I have BG12 burners that maybe aren't the best for NG, but they work.

Similar threads

- Replies

- 0

- Views

- 151

- Replies

- 1

- Views

- 1K

- Replies

- 2

- Views

- 537