Soon after posting, I had the same thought as you

@IslandLizard, the ball lock posts are essentially shutoff valves when a part is not connected. However, I hemmed and hawed about whether I wanted shutoff valves or not. I definitely need them for the pumps as I'm planning on hooking up a high powered washing pump to one end of the manifold and a lower power sani-rinse pump to the other end and I don't want backflow into the opposite pump. That was a really good idea

@Broken Crow about connecting tees. In the end I sort of compromised and decided to get 4 SS tees with nipples to connect them (which also adds some space between) and have 4 output ball lock posts and 2 input ball lock posts. The intention was originally to have 6 outputs with different things (like barbs, posts, flares, and a line for a CIP ball, spray wand), so I can easily get all my brewing cleaning done with one setup. I have a 4 tap setup but I also have 10 corny's which I do all my fermenting in as well as an assortment of ball lock gadgets (transfer lines, blow off tubes, spunding, etc). I wanted to be able to clean everything easily without having to constantly lift a Bucket Blaster into different buckets and/or modify it. I read an article a couple years ago that said invest in the cleaning side and I feel like it's an investment that will pay off and give me more time for brewing. It's also my least favorite part of brewing and holds me back often from a free time perspective.

A while back I bought a utility cart that I plan on setting up with a washing station up top that drains down to (and pumps up from) the bottom shelf. I plan on being able to adjust the depth of the CIP ball stem so it can be placed inside an inverted keg or lowered for things like carboys/growlers. I even had an idea to put an inverted 5 gallon bucket over it with a rack inside so it can be used like a dishwasher too (with the rotating CIP ball below the rack). Add in a timer for the wash pump and it becomes semi-automated. A beer funnel will be the "catch basin" and the flexible "drain hose" can be changed between buckets on the bottom shelf. There will be two 5 gallon buckets down there, one for oxygen cleaner and one for rinse water or catching starsan rinse water. There will be one bucket on the top shelf that has starsan in it (that will have the smaller pump) and that solution will drain to the discard/initial rinse water bucket because I don't plan on re-using it but it's flexible in how I decide to use the different solutions/buckets.

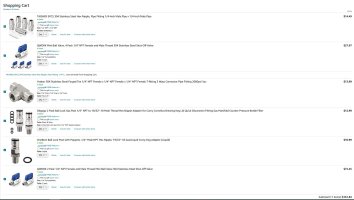

So now I have a Bucket Blaster that's going to be cannibalized, a beer funnel, a utility cart, and the parts for the manifold (que McGuyver). For now I'm going to assemble the manifold and hook it up to the weaker Bucket Blaster pump before connecting it to a stronger wash pump that I'll buy and test it out. If it seems up to the task I'll get a decent wash pump probably in the $70 range. Below are the parts I bought for the manifold (gas ball lock posts were on sale so I'll use them for the pump hookups). I ended up getting shutoff valves for each connection because I'd rather just make it awesome if I'm going to do it. The shutoff valves will help with my mental check down before I turn the pumps on and blow oxygen cleaner all over my finished basement haha. A little more than I planned on spending but I think this is a good investment. I'll try to post pics of my "Dream Clean Station" after I'm done. A lot of help from stuff I've seen on here, especially

@day_trippr, and from you guys in this thread. Cheers!