jnlipas

Member

Hi all,

Today I tried to make my first all grain batch (Ed Wort's Haus Pale Ale) and it ended up not turning out how I imagined due to a disregard on my part for setting up an actual equipment profile in BeerSmith. I downloaded a recipe for the Haus Pale Ale from BeerSmith's website:

(http://beersmithrecipes.com/viewrecipe/5993/edworts-haus-pale-ale)

and just set my equipment profile to Pot and Cooler (5 Gal/19 L) - All Grain with a batch size of 5 gallons. I picked this option because my brew kettle is 4 gallons and my mash tun is 5 gallons, so I figured this would be close enough. Once I loaded the recipe in I just scaled it down to 3 gallons and went off to the brew store to buy the equipment to do all grain as well as the grains and hops. My strike temperature was where it should have been as well as my mashing temperature, although my sparge water was a few degrees cooler than where it was supposed to be. After brewing everything I ended up with only 1.5 gallons (recipe said I should have had 2.6) and ended up with an OG around 10% ABV !

!

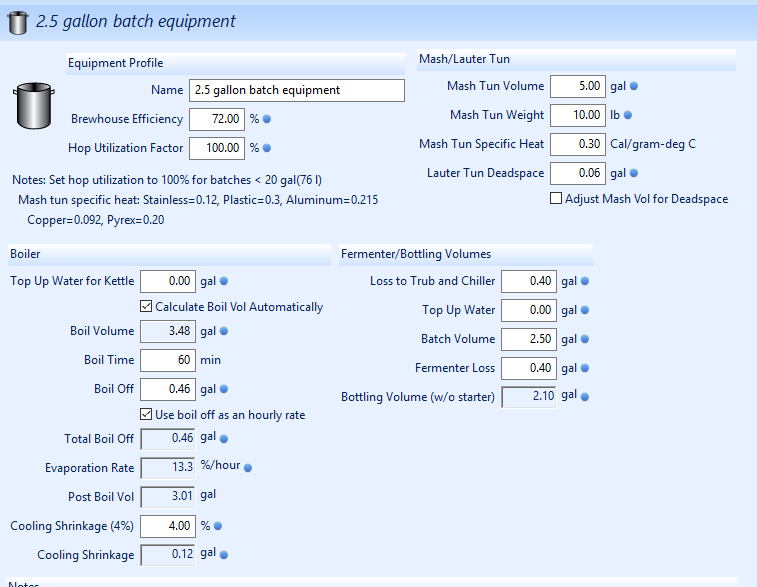

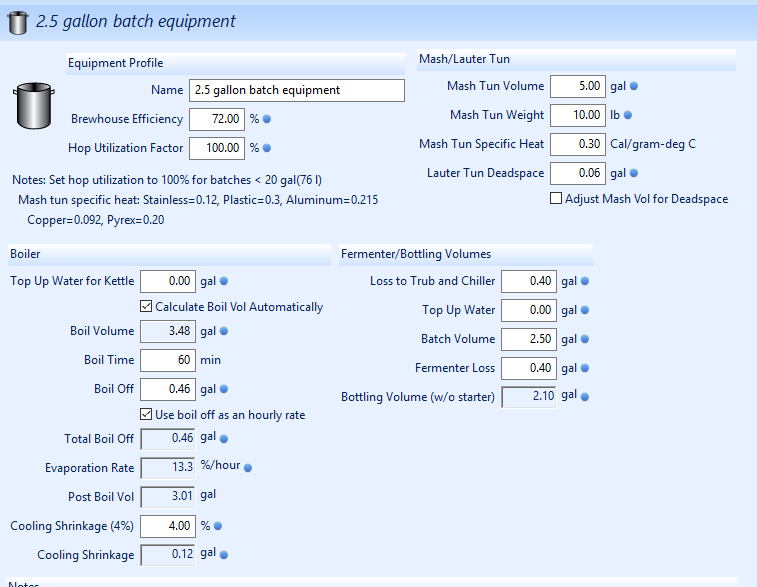

I went back through and created an actual profile in BeerSmith but this time for 2.5 gallons (I've decided to scale down from 3) following the article from Brad Smith on their website, and I was hoping that someone could look it over as well as what it spat out for the recipe scaled down to 2.5 gallons. The only thing I'm not so sure about is the deadspace: I read on either this forum or on the BeerSmith forum that to find out the deadspace, you just had to fill your mash tun with a few gallons of water then pour what was stuck under the false bottom in to a measuring cup. If anyone needs any additional information, please let me know. I'm pretty new to all grain and still have much to learn.

View attachment edworts-haus-pale-ale.bsmx

Today I tried to make my first all grain batch (Ed Wort's Haus Pale Ale) and it ended up not turning out how I imagined due to a disregard on my part for setting up an actual equipment profile in BeerSmith. I downloaded a recipe for the Haus Pale Ale from BeerSmith's website:

(http://beersmithrecipes.com/viewrecipe/5993/edworts-haus-pale-ale)

and just set my equipment profile to Pot and Cooler (5 Gal/19 L) - All Grain with a batch size of 5 gallons. I picked this option because my brew kettle is 4 gallons and my mash tun is 5 gallons, so I figured this would be close enough. Once I loaded the recipe in I just scaled it down to 3 gallons and went off to the brew store to buy the equipment to do all grain as well as the grains and hops. My strike temperature was where it should have been as well as my mashing temperature, although my sparge water was a few degrees cooler than where it was supposed to be. After brewing everything I ended up with only 1.5 gallons (recipe said I should have had 2.6) and ended up with an OG around 10% ABV

!

!I went back through and created an actual profile in BeerSmith but this time for 2.5 gallons (I've decided to scale down from 3) following the article from Brad Smith on their website, and I was hoping that someone could look it over as well as what it spat out for the recipe scaled down to 2.5 gallons. The only thing I'm not so sure about is the deadspace: I read on either this forum or on the BeerSmith forum that to find out the deadspace, you just had to fill your mash tun with a few gallons of water then pour what was stuck under the false bottom in to a measuring cup. If anyone needs any additional information, please let me know. I'm pretty new to all grain and still have much to learn.

View attachment edworts-haus-pale-ale.bsmx