Is there a place where I can send off a couple bottles and have them tell me what's wrong with my beer? I've made 30+ all-grain batches now and almost everyone of them has been barely drinkable. I have yet to make a beer that I would pay money for. I'm done trying to troubleshoot as I've tried just about everything(too long to list here). I've tried a few brewers locally and they couldn't tell me. I'm at wits end and am sick of dumping gallons upon gallons down the drain. Thanks for any input......Mark

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Still making bad beer after 30+ batches.

- Thread starter mprowland

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

http://www.beerinfo.com/index.php/pages/homebrewclubMI.html

Join a home brew club. There'll usually be a few wizened ancients that can figure out what's going on...

Cheers!

Join a home brew club. There'll usually be a few wizened ancients that can figure out what's going on...

Cheers!

theonetrueruss

Senior Member

Have you tried brewing with someone else who makes beer you like and doing one of their recipes with their guidance? There must be something off if after 30 batches you can't get a good one.

One of the best things you could do is to hook up with a local home-brew club. Have some folks give you some honest feedback. Maybe join another brewer for a couple brew days, have someone come watch you brew and give you some pointers.

http://www.homebrewersassociation.org/community/clubs/find-a-homebrew-club/

LANSING, MI

Greater Lansing Brewtopian Society

(517) 374-1070 | Email

Lansing Brew Crew

(517) 775-0119 | Email

Mid Michigan Malt Meisters

(517) 484-8145 | Email

There is no "official" place you can send your beer. You could enter some competitions. I am sure some folks on here would sample your beer and try to give you some pointers. I would try to give you some thoughts if you are interested - although, there has to be some people locally that might be able to help.

http://www.homebrewersassociation.org/community/clubs/find-a-homebrew-club/

LANSING, MI

Greater Lansing Brewtopian Society

(517) 374-1070 | Email

Lansing Brew Crew

(517) 775-0119 | Email

Mid Michigan Malt Meisters

(517) 484-8145 | Email

There is no "official" place you can send your beer. You could enter some competitions. I am sure some folks on here would sample your beer and try to give you some pointers. I would try to give you some thoughts if you are interested - although, there has to be some people locally that might be able to help.

A perfect example of determination.

Or insanity. Thin line...

Or insanity. Thin line...

Without knowing your process, its hard to say what is going wrong. For me the biggest difference came when I was able to control fermentation temperature. How are you doing that out of.curiosity?

That's a lot of bad beer. I'm honestly surprised you haven't quit by now. Cheers to persistence!

Here's the list of potential culprits, although it sounds like you have checked all this.

Is your thermometer accurate?

Does your water suck?

Do you have fermentation temperature control?

Are you making yeast starters?

What are you using to sanitize?

Have you used any kits or only made your own recipes?

Did you start with extract batches? If so was that beer good?

Here's the list of potential culprits, although it sounds like you have checked all this.

Is your thermometer accurate?

Does your water suck?

Do you have fermentation temperature control?

Are you making yeast starters?

What are you using to sanitize?

Have you used any kits or only made your own recipes?

Did you start with extract batches? If so was that beer good?

mprowland

Well-Known Member

Almost all of my recipes are from here. I've seen many people brew and watch me brew. I'm as thorough and anal as the rest of them, if not more so. No one has been able to give me any feedback as to where the taste is from.

I admire your determination... I would have given up long ago.

I would also look to contact a local brew club. Try to find someone who can brew with you to determine what you are doing wrong. Ask them for a recipe that they have done with good success. If possible try one to make sure you like it before starting. If it is something you don't like you will not know whether it is a good beer that you just don't like or a bad beer.

To be blunt, since you have not made any good beers it should be relatively easy to find the problem. There has to be something drastic in ingredients or your procedures.

I would also look to contact a local brew club. Try to find someone who can brew with you to determine what you are doing wrong. Ask them for a recipe that they have done with good success. If possible try one to make sure you like it before starting. If it is something you don't like you will not know whether it is a good beer that you just don't like or a bad beer.

To be blunt, since you have not made any good beers it should be relatively easy to find the problem. There has to be something drastic in ingredients or your procedures.

JLeuck64

Well-Known Member

I went down the same route as you, about 30 batches of home brew using extract with steeping grains. Tried everything suggested to make that brew taste better too. Darker beers turned out ok... barely. Lighter beers flat sucked. So after watching a friend brew a batch of all grain I decided I was close enough to that process, with the mini mash I was making with steeping grains, that I could make the transition into all grain with just a few more pieces of equipment. From that very first batch of AG to the present I have not been disappointed at all. Sure I've had some batches I didn't like but those were custom recipes of my own creation. Every proven recipe I've brewed, like the ones on HBT have turned out very drinkable.

My assumption is you are still brewing with extract? If so I can't promise you'll make better beer switching to AG, but the ingredients used with AG are some much better tasting than extract in my opinion. Why anyone would want to cook with it is a puzzle to me still...

I've got 62 batches under my belt since that last batch of of extract, glad those days are behind me!

I would encourage you to seek out a local brew club, brewing supply shop or a friend who makes AG beer and check out the process. Heck you don't have to go for 5gal batches to start with... 1, 2 or 3 gallon volumes will give you an opportunity to decide if it is worth continuing.

HTH

My assumption is you are still brewing with extract? If so I can't promise you'll make better beer switching to AG, but the ingredients used with AG are some much better tasting than extract in my opinion. Why anyone would want to cook with it is a puzzle to me still...

I've got 62 batches under my belt since that last batch of of extract, glad those days are behind me!

I would encourage you to seek out a local brew club, brewing supply shop or a friend who makes AG beer and check out the process. Heck you don't have to go for 5gal batches to start with... 1, 2 or 3 gallon volumes will give you an opportunity to decide if it is worth continuing.

HTH

Is there a common bad flavor that you can ID in each beer, or does it vary? If it's the same or similar off-flavor each time, we might be able to help troubleshoot. It could be something fundamental, like an infection or a water issue.

eps2103

Active Member

Curious if you've ever made one with extract which you think is decent, or at least drinkable? Your issues could related to your process, could be water, could be fermentation, could be sanitation, list goes on...

I presume by "barely drinkable" you mean that there are some wierd flavors going on. How do you describe it, and can you identify any specific off flavors you taste?

I presume by "barely drinkable" you mean that there are some wierd flavors going on. How do you describe it, and can you identify any specific off flavors you taste?

No one has been able to give me any feedback as to where the taste is from.

What is "the taste?"

mprowland

Well-Known Member

That's a lot of bad beer. I'm honestly surprised you haven't quit by now. Cheers to persistence!

Here's the list of potential culprits, although it sounds like you have checked all this.

Is your thermometer accurate?

Does your water suck?

Do you have fermentation temperature control?

Are you making yeast starters?

What are you using to sanitize?

Have you used any kits or only made your own recipes?

Did you start with extract batches? If so was that beer good?

Honestly, If I made great beer from the very beginning, I may have lost interest by now. I love the learning curve, but this has gone on long enough.

-I've been through many thermometers, I now use the little brother to the Thermopen.

-I've only used bottled water until recently, I now build my water with R.O. and BruN' water

-I don't, but I make sure the fermentation temp is ideal for the yeast I'm using. I live in quad level house, I seem to have a variety of temperatures, the lowest being 58 degrees ambient.

-I always make starters on a stir plate with liquid and rehydrate with dry yeast.

-Star San in a spray bottle to sanitize and PBW to clean.

-I've never used any kits, I've always made recipes from here that has a high post count.

Thanks for all of the responses thus far.

Answers to these questions will allow us to eliminate things and maybe narrow down what to look for.

Have you tried different water?

Have you tried different thermometers? Or at least checked the calibration?

Do you control your fermentation temperatures? Mid sixties for most ales.

Water and temperatures are the root of most problems.

Oops I type too slowly.

Have you tried different water?

Have you tried different thermometers? Or at least checked the calibration?

Do you control your fermentation temperatures? Mid sixties for most ales.

Water and temperatures are the root of most problems.

Oops I type too slowly.

jrgtr42

Well-Known Member

Not that I can tell without being there for the whole time, but it sounds like your procedures are OK, if other folks have been there while you brew, and don't see anything. What exactly is wrong with your beer? Is it off flavors, or just not up to commercial standards?

Couple things: what do you use for water? Do you use tap? If so, try buying water, be it spring or RO (if RO, build up with brewing salts and minerals; see other threads or beersmith for ideas on that)

How is your yeast health? Do you do a starter?

How is your fermentation conditions? cool and dark?

Do you bottle or keg? How are you bottling or kegging equipment - bottling bucket, siphon, hoses etc?

Couple things: what do you use for water? Do you use tap? If so, try buying water, be it spring or RO (if RO, build up with brewing salts and minerals; see other threads or beersmith for ideas on that)

How is your yeast health? Do you do a starter?

How is your fermentation conditions? cool and dark?

Do you bottle or keg? How are you bottling or kegging equipment - bottling bucket, siphon, hoses etc?

eps2103

Active Member

Do you try your hydrometer samples during fermentation, and do you get 'the taste' even before you've packaged it?

mprowland

Well-Known Member

Is there a common bad flavor that you can ID in each beer, or does it vary? If it's the same or similar off-flavor each time, we might be able to help troubleshoot. It could be something fundamental, like an infection or a water issue.

It's the same off-flavor in almost all the beers. I can't describe it but it's always on the back-end. I notice it more with porters and stouts. I still notice them in IPA's, they're just not as noticeable.

I have many friends that brew. I watch them, and they watch me. There seems to be nothing out of the ordinary. I just need someone with a technical palate for beer to tell me what's wrong. When and if I fix this issue, I have no doubt that my beer will be outstanding. I believe I have ruled out all of the rookie mistakes through this process.

jmitchell3

Well-Known Member

Try and describe the flavor you are getting if you will....

Is it a flavor? A sensation? Where exactly on the palate are you perceiving it? Does it longer or appear and disappear quickly? Is it a texture?

Can you describe:

1) your last two batches' water adjustments and target mineral profiles, along with mash ph values and beer styles

2) your sanitation practices.

3) what kind of material are your mash tun, kettle, and fermenter?

Any descriptive info on the problem and your standard procedure would be helpful.

Is it a flavor? A sensation? Where exactly on the palate are you perceiving it? Does it longer or appear and disappear quickly? Is it a texture?

Can you describe:

1) your last two batches' water adjustments and target mineral profiles, along with mash ph values and beer styles

2) your sanitation practices.

3) what kind of material are your mash tun, kettle, and fermenter?

Any descriptive info on the problem and your standard procedure would be helpful.

Last edited:

Honestly, If I made great beer from the very beginning, I may have lost interest by now. I love the learning curve, but this has gone on long enough.

-I've been through many thermometers, I now use the little brother to the Thermopen.

-I've only used bottled water until recently, I now build my water with R.O. and BruN' water

-I don't, but I make sure the fermentation temp is ideal for the yeast I'm using. I live in quad level house, I seem to have a variety of temperatures, the lowest being 58 degrees ambient.

-I always make starters on a stir plate with liquid and rehydrate with dry yeast.

-Star San in a spray bottle to sanitize and PBW to clean.

-I've never used any kits, I've always made recipes from here that has a high post count.

Thanks for all of the responses thus far.

Ok I think we have found the issues. Your water, mash temp, and yeast health should be fine, but you really need to get a chest freezer and temp controller. Also do you really only use a spray bottle of Starsan? You really need to mix up several gallons and let your fermenter soak at least 30 seconds if not longer. You may have developed an infection early on in your equipment that has wrecked all subsequent batches.

mprowland

Well-Known Member

Also do you really only use a spray bottle of Starsan? You really need to mix up several gallons and let your fermenter soak at least 30 seconds if not longer. You may have developed an infection early on in your equipment that has wrecked all subsequent batches.

Actually I do, I use it very liberally and saturate EVERYTHING with it. I use roughly 1/4 teaspoon per quart of water. I usually use the entire bottle on a brew day. I'll definitely try filling up a bucket next time.

You say you have had a bunch of people watch you brew, and you have watched them brew.....

1.) Do they brew good beer??? Beer you would pay for?

2.) Do they think your beer is bad too?

1.) Do they brew good beer??? Beer you would pay for?

2.) Do they think your beer is bad too?

EcuPirate07

Beer is a food group

Have you tried new fermentation buckets incase you did pick up so,e nasties you can't get rid of? Buckets are cheap. Worth a shot.

jmitchell3

Well-Known Member

Ok I think we have found the issues. Your water, mash temp, and yeast health should be fine, but you really need to get a chest freezer and temp controller. Also do you really only use a spray bottle of Starsan? You really need to mix up several gallons and let your fermenter soak at least 30 seconds if not longer. You may have developed an infection early on in your equipment that has wrecked all subsequent batches.

It could be an infection (that sounds like a reasonable conclusion), but starsan is a contact cleaner thus soaking should not be necessary. If the surface remains wetted for 30+ seconds it will be sanitized (given the correct starsan dosage in the initial mixture). The potency of your starsan mixture can be verified by testing the starsan mixture liquid pH. Anything below 3 should be good to go.

If he has 58F ambient temps, it's possible that during the most vigorous fermentation the internal temp of the beer could be up to 70F. However if the pitching temp is low, say in the low 60s, and the temp is allowed to free rise in that 58F ambient environment, I don't see fermentation temps necessarily getting out of hand....

eps2103

Active Member

Couple questions not answered yet though, not that I see anyway...

- Have you ever made good beer with extract?

- Can you describe the flavors you detect?

- Have you ever made good beer with extract?

- Can you describe the flavors you detect?

Everyone's trying to get to what constitutes the "off" character with no joy so far.

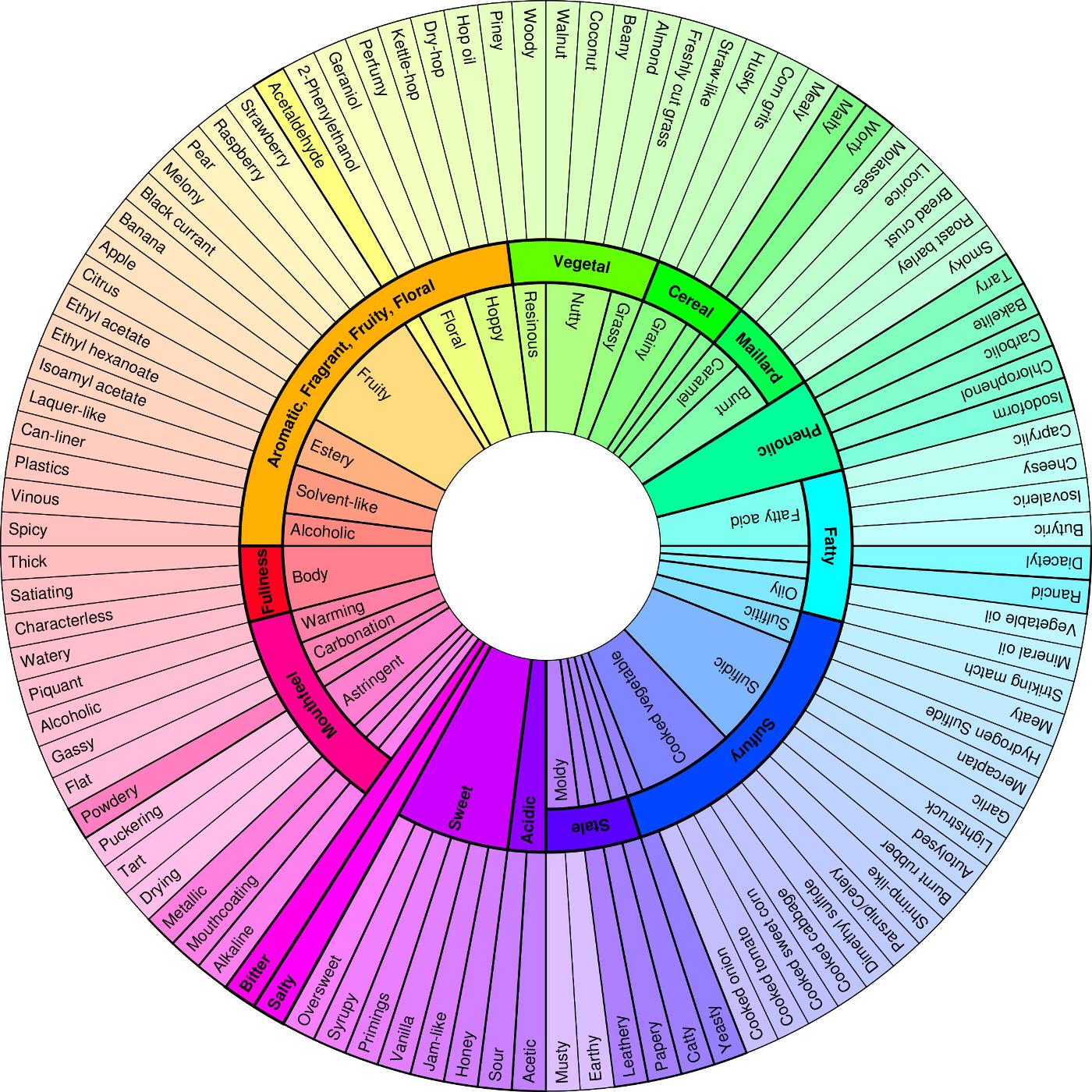

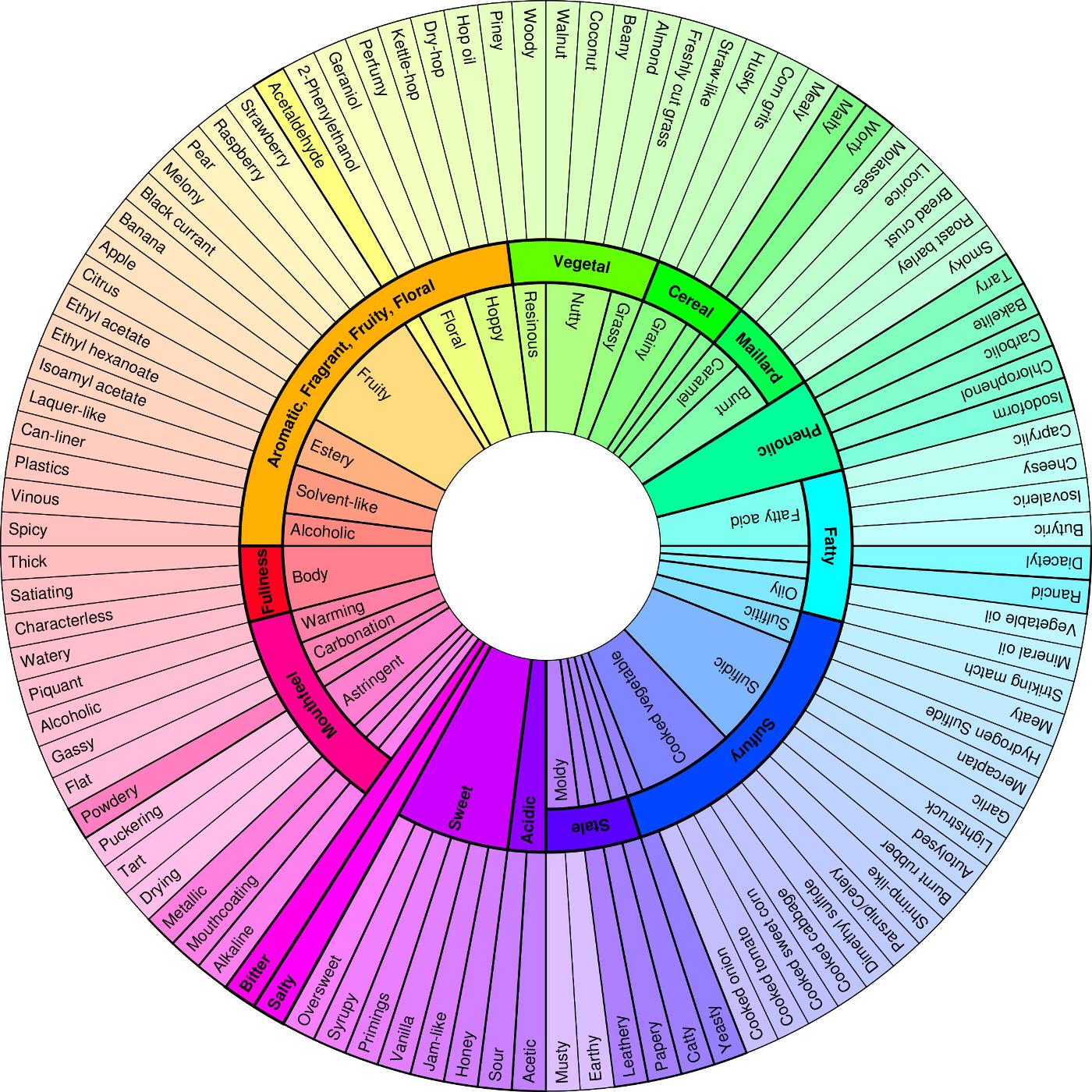

So, pick one. Or many. Whatever...

Cheers!

So, pick one. Or many. Whatever...

Cheers!

mprowland

Well-Known Member

You say you have had a bunch of people watch you brew, and you have watched them brew.....

1.) Do they brew good beer??? Beer you would pay for?

2.) Do they think your beer is bad too?

1.)Some of the beer, yes.

2.)I don't think we're honest when it comes to each others' beer. You can tell when someone really likes a beer, but not so much when they don't like it. No one wants to tell someone else that their "kid" is ugly. I've seen many a ugly baby in my day, but I would never tell that to a parent of one. When they drink my beer, the comments are few and far between. Their next beer is usually something different.

mprowland

Well-Known Member

I love the color wheel! Alcoholic, stale, dry, and sulfury(sometimes) seem close. I'll have my wife try the chocolate oatmeal porter I just kegged tomorrow to see if I can further hone in on this. Thanks!!

I made two extract batches 10+ years ago and they were terrible. I didn't start making beer again until 2 years ago. I went straight to all grain.

I made two extract batches 10+ years ago and they were terrible. I didn't start making beer again until 2 years ago. I went straight to all grain.

I love the color wheel! Alcoholic, stale, dry, and sulfury(sometimes) seem close. I'll have my wife try the chocolate oatmeal porter I just kegged tomorrow to see if I can further hone in on this. Thanks!!

I made two extract batches 10+ years ago and they were terrible. I didn't start making beer again until 2 years ago. I went straight to all grain.

What do your primary/secondary(if applicable)/bottling or kegging procedures look like? Is anyone else suspecting oxidation? All other variables, except temp control, seem to be accounted for. Does it taste like plants, cardboard, or mushy paper? That's where my head went with "dry" and "stale."

I had it once, focused on the siphon transfer to bottles and kegs, and things got better. The other culprit could be water chem, though if you're using Bru 'n water appropriately you should be fine.

A quandary indeed!

Amadeo38

Well-Known Member

It's the same off-flavor in almost all the beers. I can't describe it but it's always on the back-end. I notice it more with porters and stouts. I still notice them in IPA's, they're just not as noticeable.

This kind of thing is so frustrating... Having 5 gallons of a beer that's just barely bad enough that you're pissed to have to drink it. If you notice it more with porters and stouts, perhaps it's astringency? Are you keeping your flame on the entire time during the mash and scorching the grains perhaps?

I second the thought of grabbing a new fermentation bucket, and also agree that you don't need to soak in starsan if you've properly cleaned the item with PBW beforehand. Spray bottle contact works just fine.

Last thing I'd recommend if you don't want to invest in a fridge for fermentation temp control at this point is a Swamp cooler of some sort to help reduce temp swings if your ambient air temp fluctuates during the day.

I would suggest doing a very basic brew to help narrow it down. Have you done something very forgiving like a Hefeweizen? If not, and if you like them, get some r o water and 6 lbs wheat dme, and an oz hallertauer hops and cook up a hefe. I would say that, if it comes out drinkable, your water sucks.

Does it taste "off" in the fermenter, or after it's been packaged? If the later...

Do you bottle or keg? Run us through your process please.

Do you bottle or keg? Run us through your process please.

I would suggest doing a very basic brew to help narrow it down. Have you done something very forgiving like a Hefeweizen?

wait. no. I never tasted a good homebrewed hefeweizen. wathever the yeast, the fermentation temperature, weizen always have problems when homemade. it's the most difficult style to brew at home, not really a basic one...

I'm sure you're getting a lot of info here. Without knowing your specific process I would say get a better bottle fermentor (cheap) cuz your bucket may have some scratches which can hide bacteria in. It sounds like you are pbw and star san'ing everything which is good. Maybe look into a controlled temperature chamber. They're cheap to build if u can get ur hands on an old fridge or chest freezer.

For me, cleaning, sanitizing, and temp control have always been the factors in producing quality beer.

For me, cleaning, sanitizing, and temp control have always been the factors in producing quality beer.

You said you've had many people watch you brew. I wonder if if something is wrong in your post-brew day processes - maybe racking, kegging or bottling? That really sucks man - 30 batches and nothing to show for it. Sorry. I'd probably concede and find a new hobby if a local homebrew club can't help.

Aristotelian

Well-Known Member

- Joined

- Jul 31, 2015

- Messages

- 939

- Reaction score

- 226

I am going to go out on a limb and suggest perhaps your beer is actually fine. You are not describing particular intense off flavors as you would.expect from infection. your process is sound. Have you actually done blind taste.tests against commercial or friends homebrew? I wonder if you had a.couple bad batches early on and just got down on yourself and now you expect your beer to be bad?

Redlantern

Well-Known Member

- Joined

- Oct 28, 2015

- Messages

- 856

- Reaction score

- 261

Nevermind . tried to delete but could not

mprowland

Well-Known Member

I'll see if I can explain my process in a fairly brief manner: I start off by heating up roughly 4-gallons of mash water in a stainless pot. In the past I've used bottled water, now I use R.O. with salt additions using BruN water. I taste the water after the additions and it tastes as good as any. I heat the water up to 170-ish degrees and dump it into my 10-gallon mash tun with a false bottom. I leave the water in there until it cools to around 165 degrees. Once I get this temperature, I add the grain. I mix it all up for a few minutes and then read the temperature. I'm usually around 152(depending on recipe). Within the hour of mashing, I stir it up every 20 minutes and take a temp reading. I typically lose 2 degrees within the hour. I then vorlauf around 3-4 quarts until the cloudiness is gone. Once the initial volume has drained into my keggle, I then batch sparge by adding in another 5 gallons of 168 degree water, stir and let sit for ten minutes. I again vorlauf until clear. This leaves me with around 7-gallons of wort. I heat the wort up on a natural gas burner until the hot break. I back down the flame until I get a rolling boil. I add hops according to schedule. I typically boil for 60 minutes unless I'm making a really light beer in which I'll do 90 minutes. With 5 minutes left in the boil, I'll add my copper wort chiller into the wort. While I'm boiling/cooling the wort, I clean and sanitize everything. Everything in the post boil process is saturated in StarSan; bucket, lid, air lock, scissors, yeast package, hydrometer, graduated cylinder, and stainless mesh strainer. This is when I usually rehydrate my dry yeast. If I'm using liquid, I make a starter 36-48 hours in advance. I cool the wort to around the intended fermentation temp (66 degrees for the last batch). I drain the wort into a bucket through the stainless mesh strainer. This seems to aerate the wort fairly well. I then add the yeast and close it up and add StarSan to the airlock. I place the bucket in my basement which is currently 62 degrees ambient. I have a thermometer on top of the bucket for ambient temperature and a "stick on" lcd thermometer for approximate wort temperature. I also use an infrared thermometer to check the bucket temperature. The "stick on" thermometer and the infrared are always within 1 degree of each other. Currently this temperature is 4 degrees higher than ambient at 66 degrees. I check it once a day and make sure there are no swings in temperature. My basement is fairly consistent so I never expect any. After the fourth or fifth day, I'll bring the bucket up a level (I live in a quad level house) where the wort temperature raises to around 68 degrees. I then leave it as is for 4-5 weeks, I don't use a secondary. When it's time to keg, I completely disassemble the keg and clean and sanitize. I rack the beer into the keg avoiding any splashing. I take F.G. reading and it usually is spot on. Once the keg is full, I attach Co2 and then purge for 10-15 seconds. I place the keg into my fridge at 10 PSI and let it sit for a week. I've also force carbonated with the same results. With my last batch, the off-flavor was present going into the keg. That's it in a nut shell. I've also replaced buckets, airlocks, hoses, valves and many other things. The one thing I haven't done yet is add O2 to the wort. I've had great beer made by others without it so I don't know if it's completely necessary. See any glaring faults in my technique? Thanks for reading!

mprowland

Well-Known Member

I am going to go out on a limb and suggest perhaps your beer is actually fine. You are not describing particular intense off flavors as you would.expect from infection. your process is sound. Have you actually done blind taste.tests against commercial or friends homebrew? I wonder if you had a.couple bad batches early on and just got down on yourself and now you expect your beer to be bad?

I've actually had someone who hadn't tasted my beer say this to me. I don't think that's the case. I can tell when I make a decent one(maybe 1 in 6). This has been a lot like golf for me, one good swing will bring me back for the next round. Lately I just haven't had a good swing.

Similar threads

- Replies

- 0

- Views

- 280

- Replies

- 25

- Views

- 1K

- Replies

- 15

- Views

- 2K