Did my second BIAB brew yesterday and wound up missing my OG by several points. I'm pretty sure it's due to the crazy temperature swings I had during the mash. I heated my water up to 160, then added my grain and stirred. When the temp dropped to 155 I pulled the kettle off the burner and put it on a pallet and wrapped it with an old sleeping bag. Fifteen minutes later, the temperature was down to 148. I put the kettle back on the burner, heated it back up to 160, then pulled it off again and put it back on the pallet. By that time it had overshot to 170, so I stirred until I got the temp down to 158, then wrapped the sleeping bag around it again. Fifteen minutes later I was down to 149, so I just pulled the bag and started my boil, figuring I wouldn't get any more conversion.

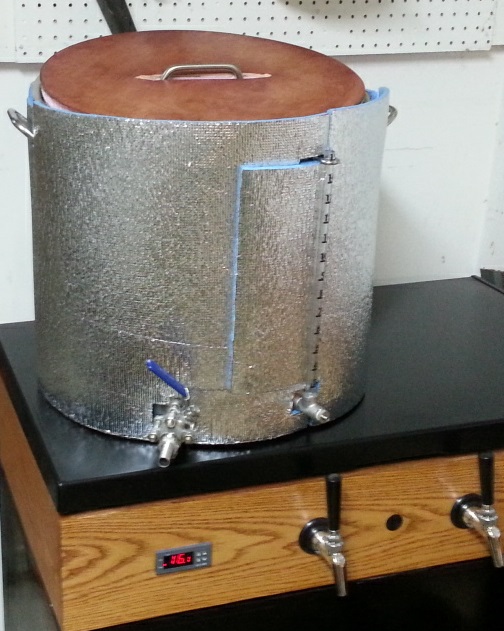

My kettle's wider than it is tall, which may be contributing to my problem, but if anyone could suggest some way to hold in the heat, I'd really appreciate it. My kettle's a decent Winco 10G SS, so it's not a thin aluminium thing. It was pretty cold yesterday (~25F with freezing rain), but I can't believe it would just cool off that fast with a sleeping bag wrapped around it.

My kettle's wider than it is tall, which may be contributing to my problem, but if anyone could suggest some way to hold in the heat, I'd really appreciate it. My kettle's a decent Winco 10G SS, so it's not a thin aluminium thing. It was pretty cold yesterday (~25F with freezing rain), but I can't believe it would just cool off that fast with a sleeping bag wrapped around it.