huntb

Well-Known Member

Finally brewed my last batch of extract last night and was able to pull the last couple of things off my old kettle in order to finish up my new eBIAB kettle. I still have a ways to go but here is where I'm at so far

Testing the pump and sprayer nozzle

And for comparison between old and new

Things to do:

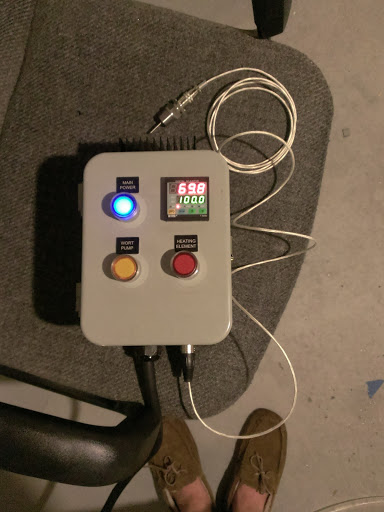

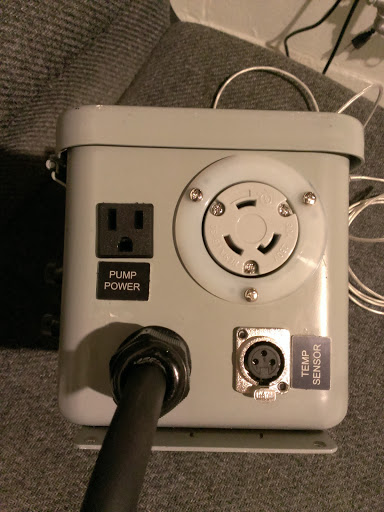

- Buy components and build control panel (probably going to go Auber for timing sake, but I really want to use Arduino) (GFCI already installed)

- Install water line and filter to brew room

- Figure out where to drain chiller and CIP waste water (thinking washing machine drain pipe, but its kinda far away)

Questions and feedback welcome

Testing the pump and sprayer nozzle

And for comparison between old and new

Things to do:

- Buy components and build control panel (probably going to go Auber for timing sake, but I really want to use Arduino) (GFCI already installed)

- Install water line and filter to brew room

- Figure out where to drain chiller and CIP waste water (thinking washing machine drain pipe, but its kinda far away)

Questions and feedback welcome