I am a total kegging noob but have a nice Sanyo for a kegerator project that I want to use.

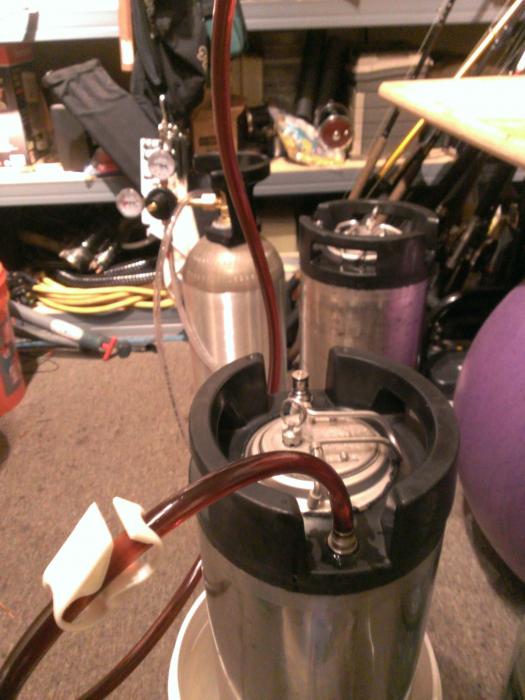

I want to ferment in my buckets/carboys and use the racking cane to rack from them into a clean and CO2 filled corny keg through the beer out post. This should put the beer in the keg without exposure to O2. Once in the keg, I will 2ndary / dry hop and then transfer the beer to a CO2 filled serving keg through a filter. Some beers may also get a little more hops in the serving keg.

My goals are to keep my fermenters free for use, avoid light and O2, and have super clear beer on tap. I would also like to be able to store beer in the kegs under CO2 until I want to tap it or until it is finished maturing (big porters, etc).

Has anyone taken this approach? Will this work? Any Gotchas?

Thanks,

Crystal

I want to ferment in my buckets/carboys and use the racking cane to rack from them into a clean and CO2 filled corny keg through the beer out post. This should put the beer in the keg without exposure to O2. Once in the keg, I will 2ndary / dry hop and then transfer the beer to a CO2 filled serving keg through a filter. Some beers may also get a little more hops in the serving keg.

My goals are to keep my fermenters free for use, avoid light and O2, and have super clear beer on tap. I would also like to be able to store beer in the kegs under CO2 until I want to tap it or until it is finished maturing (big porters, etc).

Has anyone taken this approach? Will this work? Any Gotchas?

Thanks,

Crystal