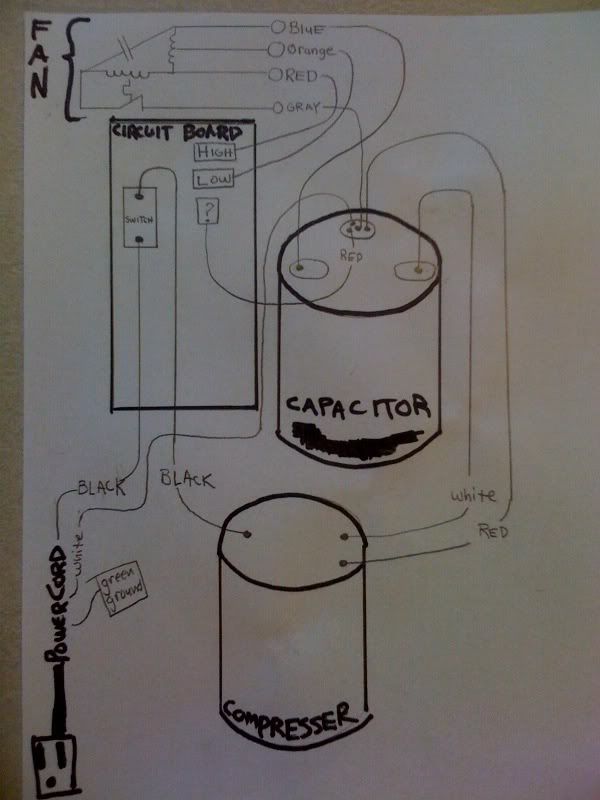

Looking for some help on this project. I just opened up the wiring box in my A/C window unit to find a birdsnest of wires, a capacitor (not even sure how these work!), and a circuit board.

I am looking for help in rewiring this so that when I plug in the A/C, both the compressor and the fan will turn on high, bypassing the temperature probe's input, and bipassing me having to hit the "power" button on the a/c control panel. I drew out all the wiring that I could see to post here if anyone could help me.

I am looking for help in rewiring this so that when I plug in the A/C, both the compressor and the fan will turn on high, bypassing the temperature probe's input, and bipassing me having to hit the "power" button on the a/c control panel. I drew out all the wiring that I could see to post here if anyone could help me.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)