It is much more important to have the pH in the correct range than arrive at some arbitrary level of calcium. Calcium is a good thing. Don't misinterpret my comment to mean it isn't and in some beers high calcium levels are fine. But many excellent beers are brewed at calcium levels well below 50 ppm.

Everything I have read has suggested you get to 50ppm in the mash to help with protein break and proper enzymatic function in the mash tun. Low levels of calcium can cause slower enzymatic function, which is precisely why a Bo Pils needs a long step or decoction mash to fully convert and prevent chill haze. Whether you end up at 50ppm in the finished beer is a different issue. I add a very small amount of salts to the mash get over 50ppm calcium since my water is 46ppm. 25ppm of calcium is probably sufficient for yeast flocculation, but I would not want to brew with water under 25ppm calcium because the yeast will not flocculate properly. Jamil and White recommend 50ppm calcium for the yeast so I aim for 50ppm in the finished beer.

There is a great deal of difference. ... When neutralizing alkalinity with acid an equivalent amount of the anion of the acid remains:

HCO3- + HAc ---> CO2 + Ac- + CO2

Very good point. I use lactic or phosphoric acid, because both of the anions have very little flavor contribution to the finished beer. Using other acids (eg sulfuric) would change the water profile in a way that would impact flavor and would need consideration, since the acid is also an implicit salt addition. The vast majority of pro brewers I know use phosphoric acid for pH adjustment because it is tasteless, and do very little else aside from filtering the water. Myself, I use lactic acid in German beer styles since it is closer to saurmalz, and I use phosphoric acid in all other beer styles.

Neither temporary or permanent hardness are changed by acid addition:

Correct; this is why I noted it is undesirable to have too much calcium in your water profile, since it will result in more CaCO3 in the finished beer, which gives a chalky, mineral flavor that an experienced beer judge can immediately pick up on, and others will find makes the beer lifeless and uninteresting. If you want sulfate, it's better to use MgSO4 since it will result in less alkalinity in the finished beer, but even then you don't want to overdo it since the coefficient is half that of calcium. For chloride ions, I often add table salt, since my water is very low in sodium.

I am only concerned with permanent hardness of my water; temporary hardness should be removed during the boil (or decoction), right? This is essentially what "permanent" hardness vs temporary means, the permanent hardness is CaCO3 (chalk) that will remain even if you boil the water, whereas the temporary hardness will precipitate out of solution during the boil. You can only reduce the permanent hardness by diluting with RO or by using slaked lime to precipitate out carbonate as CaCO3 in the liquor tank (my understanding is that slaked lime additions must be done before the mash where phosphates are present, and the settling takes awhile, which is why I just dilute with RO if I want less total hardness).

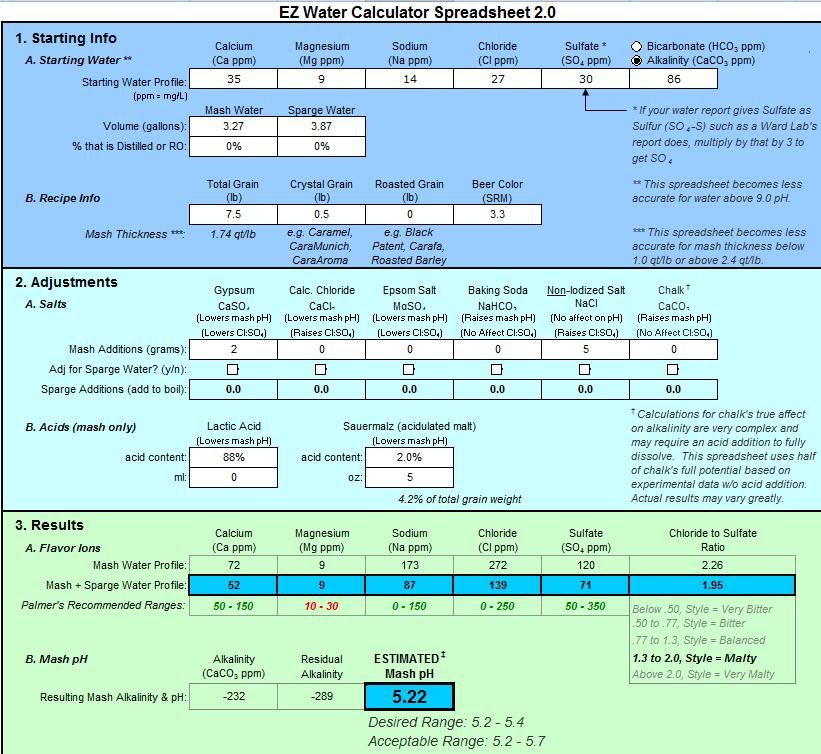

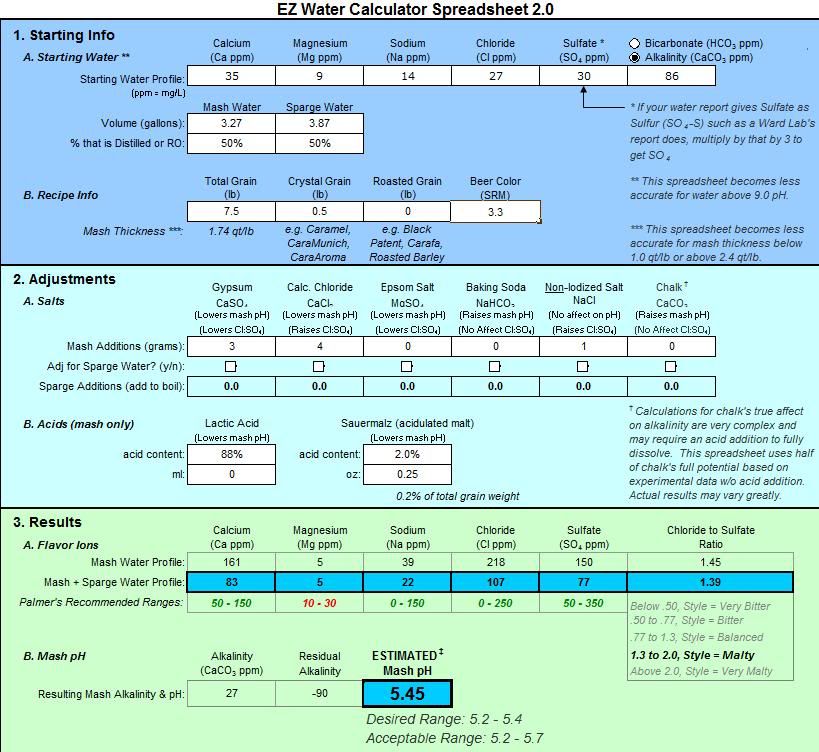

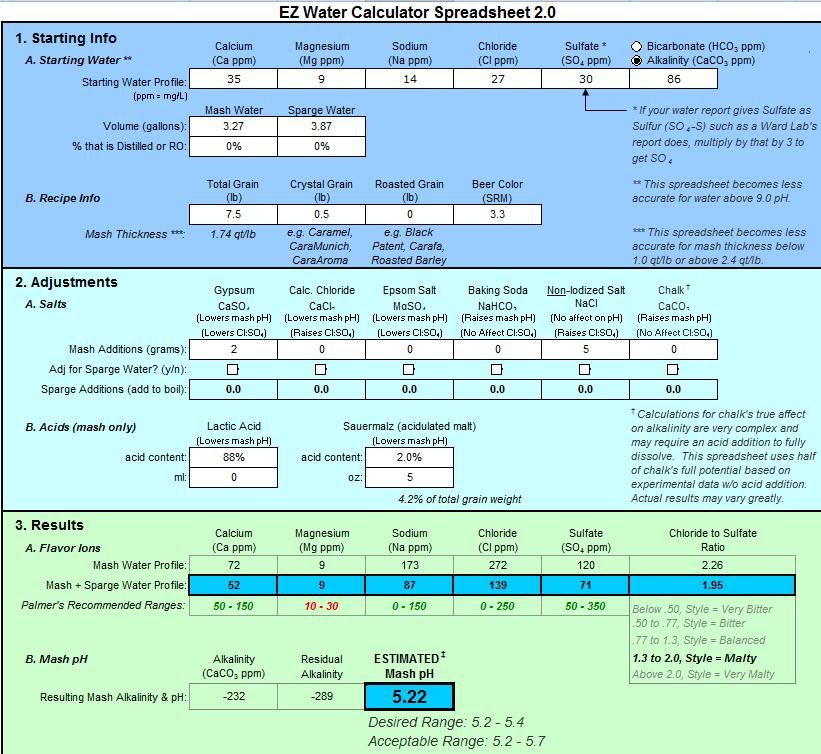

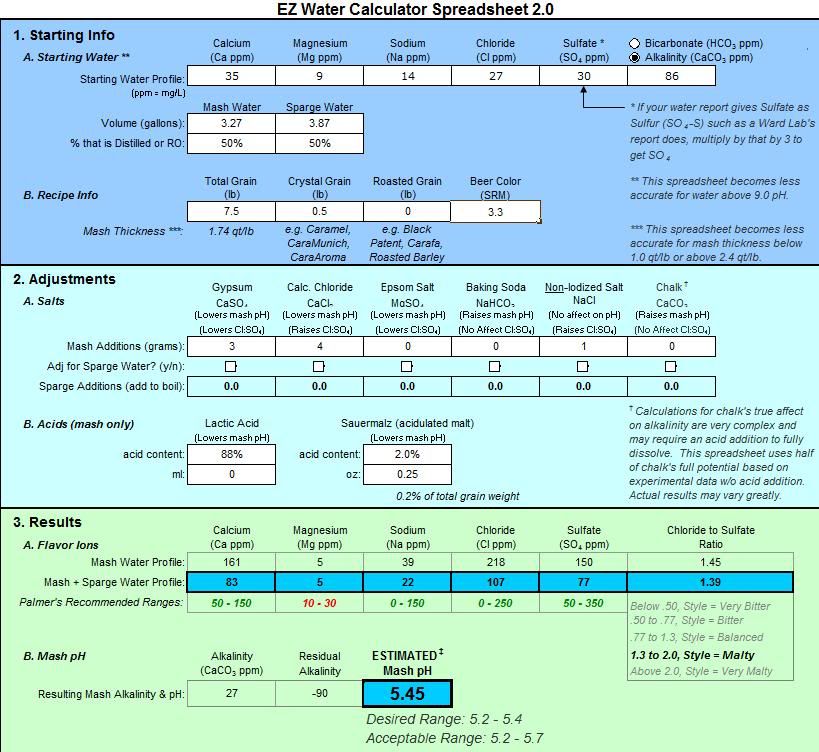

I like your comment that you should think of RO as a negative salt addition... this is exactly how I use it. I also have sent my RO water to Ward Labs, and determined the rejection rate of the RO membrane at my local store is 92%. Since 8% of the minerals of my water profile remain in the RO, it's perfectly suitable for a Bo Pils or a American Light Lager with only a little bit of acid to adjust mash pH. I use acid and a small amount of calcium chloride or gypsum in my tap water for every other beer style I brew, since light lager is (in my experience) the only beer style where total hardness seems to impact the beer flavor in a noticeable way.

This is a convoluted way of saying "don't sparge with alkaline water" and that's good advice.

Yep.

Treatment of sparge water is something that in general does not need to be done. You aren't going to mash with alkaline water and so, unless there are special circumstances, the water you mash with is suitable for sparging. I don't know why homebrewers seem to think they need to treat mash and sparge water separately.

Exactly; you don't. However I don't need to add much calcium to my water, since I have 46ppm calcium, so I use a small amount of a calcium salt (1tsp or less per 5 gal) in the mash plus acid, and then just add acid to the sparge water to arrive at my desired water profile in the resulting wort.

It's worth noting many pro breweries I have been to have a system that filters the water to remove chloramine, and adds acid to the water as it comes into the HLT and CLT (CLT = cold liquor tank) at a rate to result in a pH of about 5.7. So, all of the water is already treated to neutralize the alkalinity for proper mash pH and sparge. In essence they end up doing exactly what I do, which is add just a tiny amount of salts to the mash or kettle to adjust the water profile.

As Gordon Strong says it's more important to be consistent in your water treatment, than to try to target a particular profile, since it just adds another variable that is difficult to control. If you start with the same water adjustments for each brew, you can control other variables such as hopping and specialty malts to adjust the flavor of the beer, rather than adding a more difficult and inconsistent variable by screwing with the water too much.

Even if you go over 6 and extract some of the dreaded polyphenols these will complex with protein and settle out during conditioning. You may have to wait a little longer for your beer to be ready to drink but it's not the end of the world.

While I agree in principle, my experience as a beer judge is that this is not true. Most brewers bottle their beer too soon after brewing for polyphenols to settle out, and they also do not use positively charged finings which will help precipitate out polyphenols (silicon dioxide, kieselsol, PolyClar). As a result, astringency from oversparging or from mini-mash with alkaline water is the #1 off flavor I see in beers. The #2 off flavor is chlorophenol, which results from chloramine in the brewing water that was not removed, either from not filtering the water, or not using enough (or any) Campden to volatilize the chlorine and drive it off prior to malt contact.