It's finally happening to us in our house. We're getting older. I've always been a bit of a 135 pound weakling, but last weekend when Bob helped me move carboys around for racking he said something like "I don't know how much longer I can do this." He LOVES the wine and that's his favorite product I make around here, but hauling full carboys up to the kitchen island for racking and then hauling the filled carboys back to the fermentation area is becoming difficult. We racked 11 gallons of beer to kegs, and 15 gallons of wine to new carboys.

So I was thinking of the two issues here. One is lugging full carboys from place to place. Maybe a hand truck/dolly could help with that. The other is lifting to use gravity for siphoning. Maybe a pump could help with that?

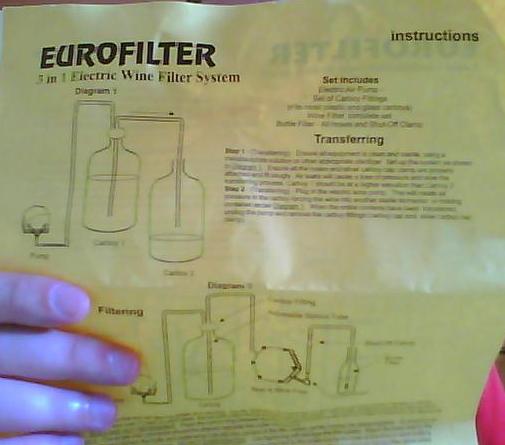

I have a March pump in the brewery, but I was wondering if maybe a filter set up (without using the pads) would be what I would need. I don't really want to filter, and certainly not at every racking anyway. But a pump that would allow me to not need to lift up a full 6 gallon carboy for racking would be great!

Anybody have any thoughts or ideas?

Sympathy on getting older?

So I was thinking of the two issues here. One is lugging full carboys from place to place. Maybe a hand truck/dolly could help with that. The other is lifting to use gravity for siphoning. Maybe a pump could help with that?

I have a March pump in the brewery, but I was wondering if maybe a filter set up (without using the pads) would be what I would need. I don't really want to filter, and certainly not at every racking anyway. But a pump that would allow me to not need to lift up a full 6 gallon carboy for racking would be great!

Anybody have any thoughts or ideas?

Sympathy on getting older?