- Joined

- Feb 11, 2008

- Messages

- 97

- Reaction score

- 0

Before I make the leap into a BCS460, I was hoping for a bit of help with an idea.

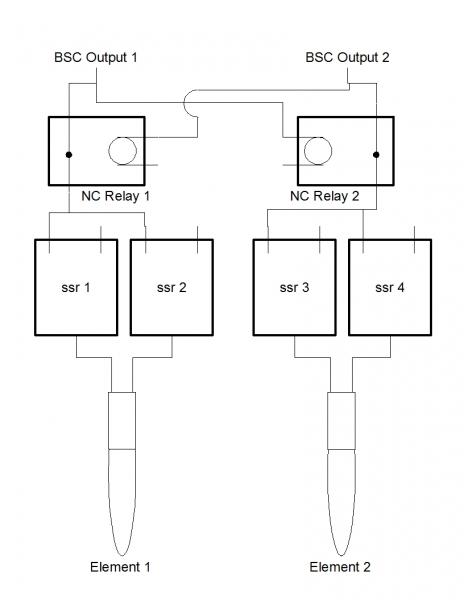

I currently have 30A service to my electric brewery. Not a problem since I only control one 5500W element. My new system will require the use of a RIMs element and a boil kettle element that cannot be operated at the same time (both will be at least 4500W.) I am hoping to have the BCS make sure that only one can operate at a time.

1) Can the BCS be easily programed to guarantee only one of the elements will be operated at a time? I need to be guaranteed that they will be locked out from firing at once so I do not have to worry about constantly blowing the breaker.

2) The option I figured out to guarantee it would be the use of a relay to switch the power. I am not sure of the terminology of relays (Double pole, double throw, I think), but I think I need one with a 5V DC coil that will have one 5V Normally Open and one 5V Normally Closed leg. My thought is to use this relay to control which element is allowed to receive input from the other BCS outputs.

I know I would put a selector switch between the two elements, but I would rather be more automated and have less chance that I will screw the system up by forgetting to flip the switch. So I guess I would want to use one output to control element 1, another to control element 2 and a third to control the relay switch. I think this will work, but I have no idea how to read relays that can work for this type of application.

Thanks for the input,

Scott

I currently have 30A service to my electric brewery. Not a problem since I only control one 5500W element. My new system will require the use of a RIMs element and a boil kettle element that cannot be operated at the same time (both will be at least 4500W.) I am hoping to have the BCS make sure that only one can operate at a time.

1) Can the BCS be easily programed to guarantee only one of the elements will be operated at a time? I need to be guaranteed that they will be locked out from firing at once so I do not have to worry about constantly blowing the breaker.

2) The option I figured out to guarantee it would be the use of a relay to switch the power. I am not sure of the terminology of relays (Double pole, double throw, I think), but I think I need one with a 5V DC coil that will have one 5V Normally Open and one 5V Normally Closed leg. My thought is to use this relay to control which element is allowed to receive input from the other BCS outputs.

I know I would put a selector switch between the two elements, but I would rather be more automated and have less chance that I will screw the system up by forgetting to flip the switch. So I guess I would want to use one output to control element 1, another to control element 2 and a third to control the relay switch. I think this will work, but I have no idea how to read relays that can work for this type of application.

Thanks for the input,

Scott