Stevorino

Well-Known Member

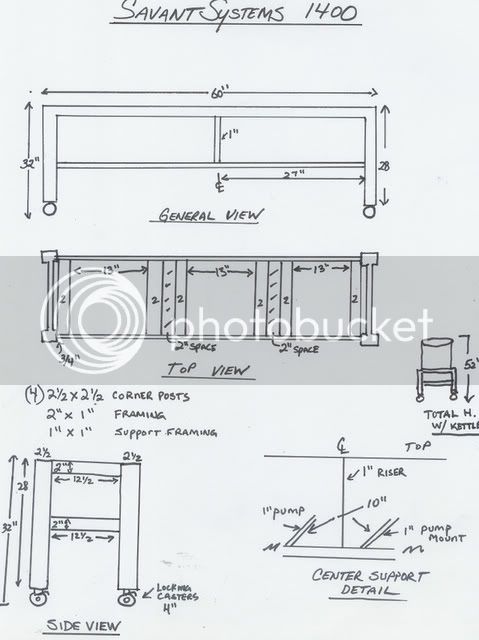

I'm handing off my plans to the welder tonight. He essentially is going to build this thing for less than I the cheapest welding gun I can find in Atlanta ($250). I'm stoked.

I'm essentially building the "Brutus 10" minus the HERMS capabilities (for now).

Here are my questions:

1) In the Brutus 10 setup, Lonnie uses 14 Gallon pots, not converted kegs. He has a 12" by 12" square that each pot rests on. Each beam is 2 inches and there is a 2 inch gap between each "burner square".

Because converted kegs (what I use) are 16 1/8" wide, there would be 1/16" overlap past the beam on each side of the square...would you all suggest widening the squares or do you think that overlap is ok?

2) The build is 28" tall plus casters that look another 3-4 inches for a total of about 32" tall -- any recommendations? I want to be able to mess with everything without using a step stool or standing on my tippy toes (lol).

3) I'm going to have the welder build the "arm" for a panel later -- any other suggestions for modifications to the Brutus 10 build?

I'm essentially building the "Brutus 10" minus the HERMS capabilities (for now).

Here are my questions:

1) In the Brutus 10 setup, Lonnie uses 14 Gallon pots, not converted kegs. He has a 12" by 12" square that each pot rests on. Each beam is 2 inches and there is a 2 inch gap between each "burner square".

Because converted kegs (what I use) are 16 1/8" wide, there would be 1/16" overlap past the beam on each side of the square...would you all suggest widening the squares or do you think that overlap is ok?

2) The build is 28" tall plus casters that look another 3-4 inches for a total of about 32" tall -- any recommendations? I want to be able to mess with everything without using a step stool or standing on my tippy toes (lol).

3) I'm going to have the welder build the "arm" for a panel later -- any other suggestions for modifications to the Brutus 10 build?