Hi guys,

I recently built a home brew PID controller modeled after Electric Brewery's control panel. I have a HERMS system.

I purchased 3 Inkbird PID controllers (ITC-100VH). My system is 240V, 5500W elements using PT100 RTDs. I have 40A SSRs.

I tried to calibrate the system in auto mode for the first commissioning of the controller. The RTD in the mashtun temp feeds the PID for the boil kettle to provide closed-loop control (as opposed to reading mash tun and HLT on their own, looking at the difference in temps, and open loop/manually setting my temp in my HLT to compensate for the system heat loss).

I set the SV = 64.4°C (148°F). The PV on the PID achieved the SV, and I would have expected some overshoot, then turning off the SSRs, allowing the temp to drop, then turn back on to zero in/ dampen the oscillations and understand the heat losses of the system.

The SSR never turned off, even when PV >>> SV. I let it keepp going up to 90°C, and the system never stopped powering the element. At this point, I set the Hi Alarm to a value (15°) below the current PV value of 85°C. The PID control went into alarm mode, shown on its screen. However, the NO relay in the PID did not trip the buzzer/lamp alarm. It appears the controller is faulty in not only controlling temp, but the relay NC alarm circuit also does not work.

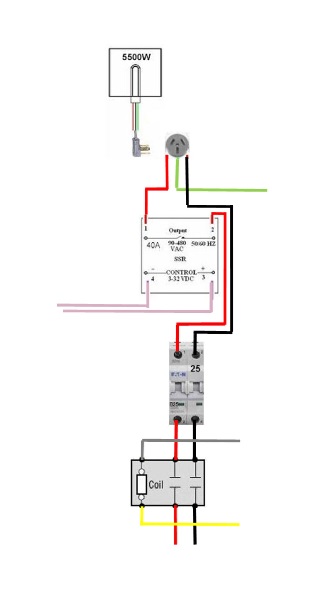

Can anyone find any issues with my diagram?

I have attached an abbreviated schematic of the HLT circuit to ask for help.

I recently built a home brew PID controller modeled after Electric Brewery's control panel. I have a HERMS system.

I purchased 3 Inkbird PID controllers (ITC-100VH). My system is 240V, 5500W elements using PT100 RTDs. I have 40A SSRs.

I tried to calibrate the system in auto mode for the first commissioning of the controller. The RTD in the mashtun temp feeds the PID for the boil kettle to provide closed-loop control (as opposed to reading mash tun and HLT on their own, looking at the difference in temps, and open loop/manually setting my temp in my HLT to compensate for the system heat loss).

I set the SV = 64.4°C (148°F). The PV on the PID achieved the SV, and I would have expected some overshoot, then turning off the SSRs, allowing the temp to drop, then turn back on to zero in/ dampen the oscillations and understand the heat losses of the system.

The SSR never turned off, even when PV >>> SV. I let it keepp going up to 90°C, and the system never stopped powering the element. At this point, I set the Hi Alarm to a value (15°) below the current PV value of 85°C. The PID control went into alarm mode, shown on its screen. However, the NO relay in the PID did not trip the buzzer/lamp alarm. It appears the controller is faulty in not only controlling temp, but the relay NC alarm circuit also does not work.

Can anyone find any issues with my diagram?

I have attached an abbreviated schematic of the HLT circuit to ask for help.