caioz1jp

Well-Known Member

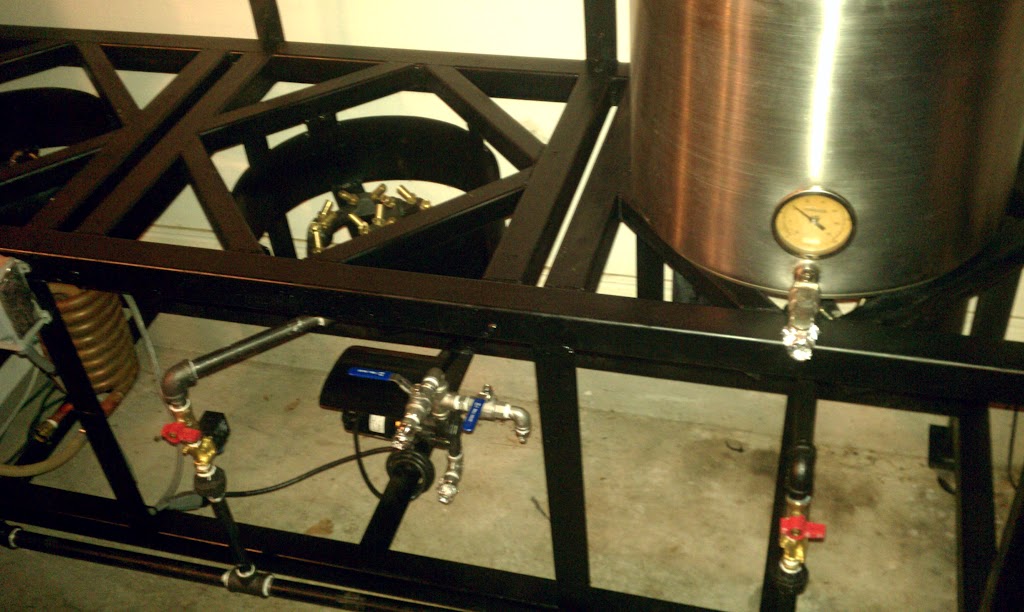

So i am doing a weldless strut stand build. I have been trying to find information on positioning and priming the pump but apparrently search "how to prime a chugger pump" yeild absolutly nothing on priming a pump. I have read that the outlet should be in the 12 position and the inlet at the 6. I have not seen one build on this site with the pump in anything but a horizontal 9 in and 3 out. Any explinations of this would be great.