Brewpastor

Beer, not rocket chemistry

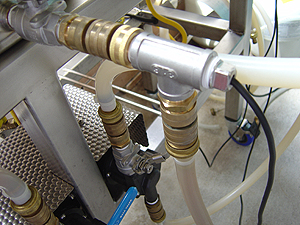

I am putting a RIM on my set-up. I have a 1500 W, 120 V element, the hardware to put it into a 1.5" stainless T, a dedicated pump, a Ranco controller, and a thermo well for the probe. My thought is to wire the controller into a socket and then plug the element and the pump into the controlled sockets.

I think I will draw out of the MLT manifold and flow it back into a slightly submurged ring at the top of the grain bed.

The thermo well will go into the MLT, resting near the bottom.

What am I missing, what is your advice?

I think I will draw out of the MLT manifold and flow it back into a slightly submurged ring at the top of the grain bed.

The thermo well will go into the MLT, resting near the bottom.

What am I missing, what is your advice?