PowderedToast

New Member

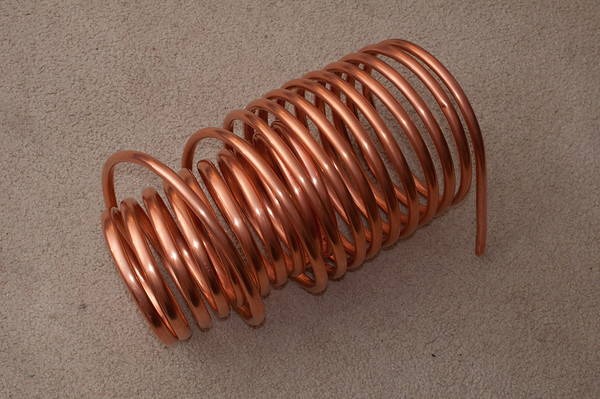

Just started brewing and quickly discovered the importance of a quick cold break. My first 5 gal. batch was cooled in an ice bath, hour+ to pitching = meh. The second was with a rinky dink 3/8" <20ft immersion chiller that a friend graciously donated - not bad, but still took a good 15 minutes. Finally, I decided to make my own. Took many a trip to a many home depot to find the right coil of copper, then settled on a 50 foot 5/8" OD. I have not seen an immersion chiller of that size on the web for purchase, so I figured this should be good. After about 3 hours, which involved looking for bending apparatuses and strategies that would reduce the amount of tube kinkage, as well as consumption of potent potables, we have das überimmersionchiller:

$108 + tax:

9" pot resulted in a 10.5" diameter outer coil:

If you have no experience with copper, it's a rather soft metal, but not as soft as you imagine. I was sweating somethingawful by the end of this excercise.

I quickly realized my IC was growing vertically quicker than anticipated. Since I use a 20qt pot, most of it was going to end up above sea level, which is a waste.

I kicked around the idea of having an inner coil. And found my heavy 10lb CO2 tank perfect for the job. Heavy is good, heavy is reliable. If it doesn't work, you can always make a wort chiller with it.

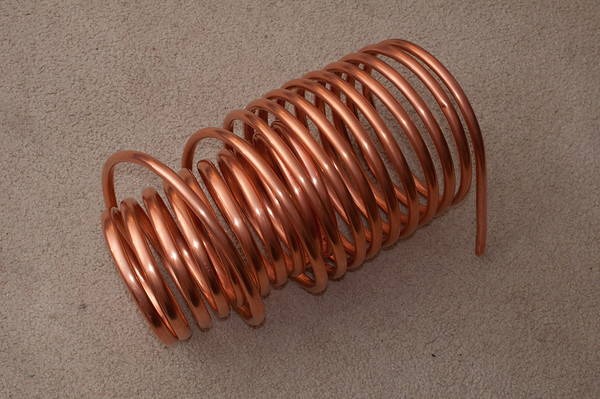

The idea is to take your time and let the copper bend itself under it's own tugging and wrapping force. Forcefully bending results in insta-kinks.

By the time I got here, I was perplexed as to how to get it inside without undue kinking.

I had to stretch out and unroll some of the outer coil...

Once you get here, you're pretty much home free.

$108 + tax:

9" pot resulted in a 10.5" diameter outer coil:

If you have no experience with copper, it's a rather soft metal, but not as soft as you imagine. I was sweating somethingawful by the end of this excercise.

I quickly realized my IC was growing vertically quicker than anticipated. Since I use a 20qt pot, most of it was going to end up above sea level, which is a waste.

I kicked around the idea of having an inner coil. And found my heavy 10lb CO2 tank perfect for the job. Heavy is good, heavy is reliable. If it doesn't work, you can always make a wort chiller with it.

The idea is to take your time and let the copper bend itself under it's own tugging and wrapping force. Forcefully bending results in insta-kinks.

By the time I got here, I was perplexed as to how to get it inside without undue kinking.

I had to stretch out and unroll some of the outer coil...

Once you get here, you're pretty much home free.