weathejx

Well-Known Member

Next brew is coming up and I needed a better way to chill my wort (read: sticking pot in sink full of ice is lousy).

So I checked out this thread and this thread and got some ideas.

I went and picked up some copper, some tubing and some misc hardware. Turns out all I needed was the copper and tubing.

Copper - $19.68.

Tubing - $6.88.

Worm Clamps - Had some laying around.

The copper i got was already coiled, so I found the midpoint, stretched it out a bit and then spaced the coils. I then bent the pipe up a bit at the end. I cut the vinyl in to about two 7' and a 6'. I attached the two 7' lengths to the pipe with worm clamps.

At this point I thought that I would need to wait until I found some more parts (lowes was missing the bushing), and then I took apart the sprayer on my sink, to find a 3/8th barb!

Connected the tube to the barb with another worm clamp and bam! working chiller. The whole thing took about 15 minutes.

Ill update once I actually use it and let you know how it works.

John

Full setup:

Water in/out:

Ribs:

Sprayer Connection:

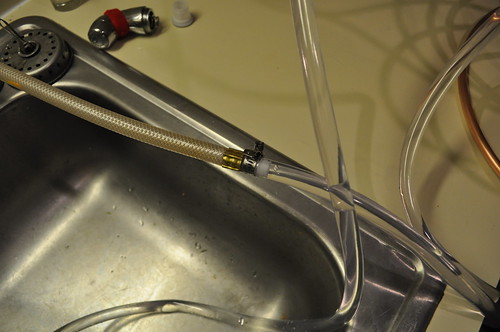

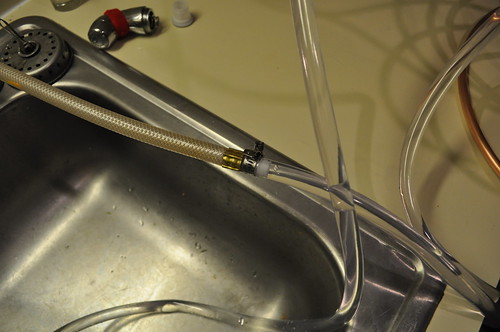

IC Connected to Spayer:

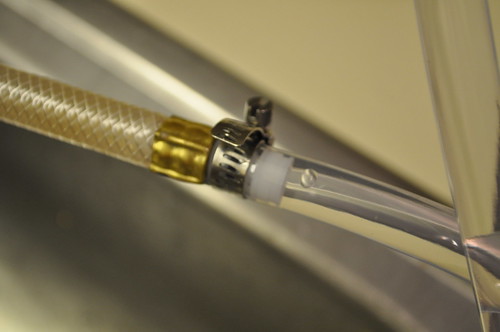

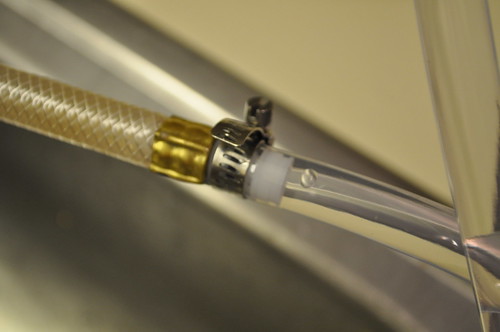

IC/Sprayer Connection Closeup:

So I checked out this thread and this thread and got some ideas.

I went and picked up some copper, some tubing and some misc hardware. Turns out all I needed was the copper and tubing.

Copper - $19.68.

Tubing - $6.88.

Worm Clamps - Had some laying around.

The copper i got was already coiled, so I found the midpoint, stretched it out a bit and then spaced the coils. I then bent the pipe up a bit at the end. I cut the vinyl in to about two 7' and a 6'. I attached the two 7' lengths to the pipe with worm clamps.

At this point I thought that I would need to wait until I found some more parts (lowes was missing the bushing), and then I took apart the sprayer on my sink, to find a 3/8th barb!

Connected the tube to the barb with another worm clamp and bam! working chiller. The whole thing took about 15 minutes.

Ill update once I actually use it and let you know how it works.

John

Full setup:

Water in/out:

Ribs:

Sprayer Connection:

IC Connected to Spayer:

IC/Sprayer Connection Closeup: