JonClayton

Well-Known Member

I will be picking up my new brew stand this weekend from the gentleman that built it for me. This will be my first time brewing on a stand setup and my biggest goal is to really try to get a handle on controlling my mash temps so that I can recreate my recipes down the road.

I put a lot of thought into this and asked a lot of questions before passing the design off to my welder, but I guess the thing I never really thought of was the various methods or controlling temp on the recirculating mash. I designed the system to be direct fire and will be using my march pump to circulate water from under the false bottom back into the top of the keggle passing through a section of loc-line inside the keggle to control height of discharge (thanks BobbyM for that idea). I just assumed that when temp begins to drop I will fire the NG burner for a moment until the temp comes back up.

I am now being told by others that this will never work and by the time the thermometer catches up and I shut off the burner I will have over shot my mash temp. Is this really much of a problem?

This has started me down the road of looking at basic PID control for my unit. My first question would be that minus the automation, how is PID any better than manual control of the burner? PID would still fire the burner off and on based on the reading from the probe and therefore be subject to the same over shooting as I am being warned about?

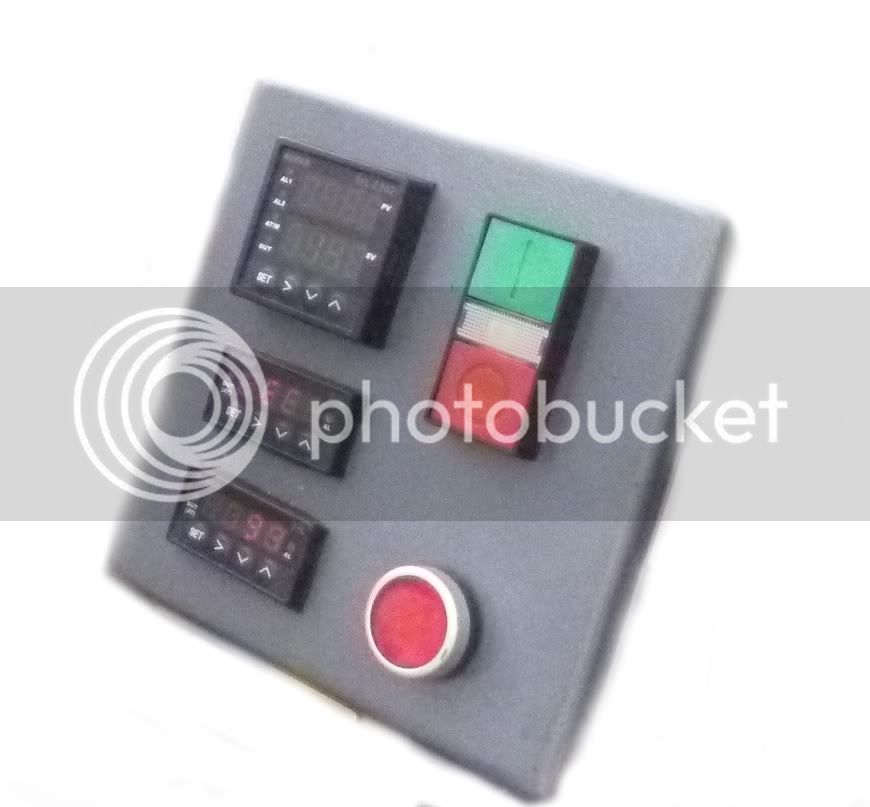

If I did decide to add PID to control the NG burner, what is the simplest way to accomplish this? I've seen some pretty elaborate systems being controlled by brewtroller etc. I also remember seeing a stand a while back that was nothing more than some sort of hot water heater control module, a thermometer and a digital display without any sort of fancy controller. I must admit that when reading about PID control on the forums some of the wiring diagrams and such shoot over my head, so if anyone has an links to past discussion or demonstration of a basic PID controlled burner please let me know.

Lastly I could also still add an electric rims system. It seems from reading and talking with other brewers that an electric rims is the best for really controlling the mash temp. Is this true?

I've already bought and had the burner installed under the MT but there is nothing saying I have to use it. At the moment I have the budget to do whatever I need to do to make this work well within reason so I want to do it right. At the same time, if I sticking to my original plan of manually controlling the burner would work well enough then there is no reason to waste money.

What say ye?

I put a lot of thought into this and asked a lot of questions before passing the design off to my welder, but I guess the thing I never really thought of was the various methods or controlling temp on the recirculating mash. I designed the system to be direct fire and will be using my march pump to circulate water from under the false bottom back into the top of the keggle passing through a section of loc-line inside the keggle to control height of discharge (thanks BobbyM for that idea). I just assumed that when temp begins to drop I will fire the NG burner for a moment until the temp comes back up.

I am now being told by others that this will never work and by the time the thermometer catches up and I shut off the burner I will have over shot my mash temp. Is this really much of a problem?

This has started me down the road of looking at basic PID control for my unit. My first question would be that minus the automation, how is PID any better than manual control of the burner? PID would still fire the burner off and on based on the reading from the probe and therefore be subject to the same over shooting as I am being warned about?

If I did decide to add PID to control the NG burner, what is the simplest way to accomplish this? I've seen some pretty elaborate systems being controlled by brewtroller etc. I also remember seeing a stand a while back that was nothing more than some sort of hot water heater control module, a thermometer and a digital display without any sort of fancy controller. I must admit that when reading about PID control on the forums some of the wiring diagrams and such shoot over my head, so if anyone has an links to past discussion or demonstration of a basic PID controlled burner please let me know.

Lastly I could also still add an electric rims system. It seems from reading and talking with other brewers that an electric rims is the best for really controlling the mash temp. Is this true?

I've already bought and had the burner installed under the MT but there is nothing saying I have to use it. At the moment I have the budget to do whatever I need to do to make this work well within reason so I want to do it right. At the same time, if I sticking to my original plan of manually controlling the burner would work well enough then there is no reason to waste money.

What say ye?