gio

Well-Known Member

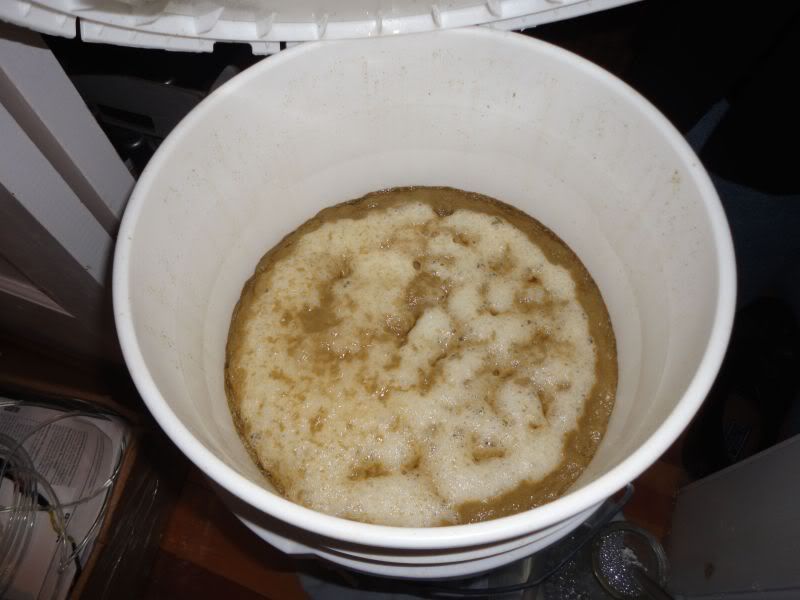

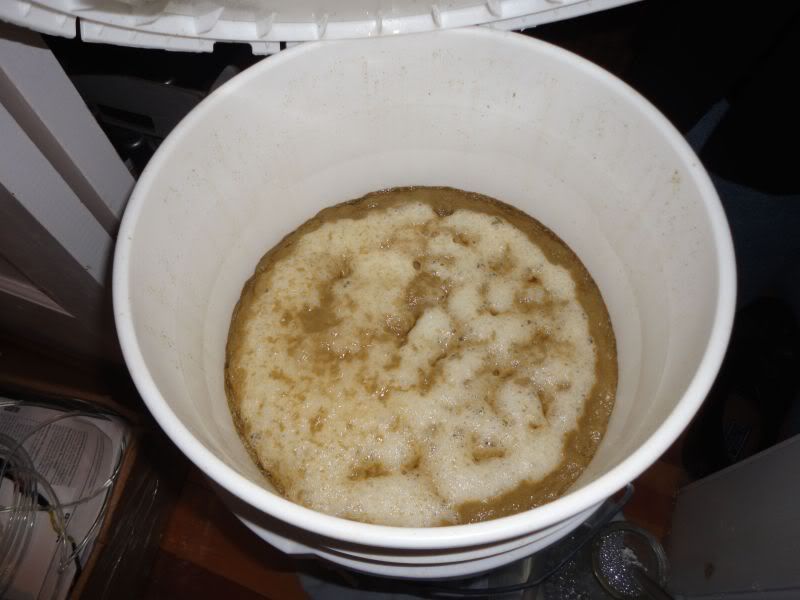

I brewed a hefeweizen yesterday and everything seemed to be going well, but today, almost exactly 24 hours after I pitched the yeast the fermenter has been giving off a horrible sulfur smell. Here are the details:

The yeast is Wyeast 3068 and the beer is a hefeweizen. I pitched at 72 degrees and dropped the temperature to 66 degrees. It climbed back up to about 68 degrees and has been at about 68 all day according to my lcd stick-on thermometer. Fermentation has been vigourous and started within 10 hours of pitching the yeast. I'm using a blowoff tube and a flask of sanitzer. I very quickly opened the fermenter to take a quick picture (see below). I've actually never done that before so I'm even sure what it is supposed to look like. Is it infected? If not, what should I do to clear up the smell (leave it extra long in the primary before transferring to the secondary perhaps? Or maybe let it rest in the secondary at a low temperature?)

The yeast is Wyeast 3068 and the beer is a hefeweizen. I pitched at 72 degrees and dropped the temperature to 66 degrees. It climbed back up to about 68 degrees and has been at about 68 all day according to my lcd stick-on thermometer. Fermentation has been vigourous and started within 10 hours of pitching the yeast. I'm using a blowoff tube and a flask of sanitzer. I very quickly opened the fermenter to take a quick picture (see below). I've actually never done that before so I'm even sure what it is supposed to look like. Is it infected? If not, what should I do to clear up the smell (leave it extra long in the primary before transferring to the secondary perhaps? Or maybe let it rest in the secondary at a low temperature?)