WPStrassburg

Well-Known Member

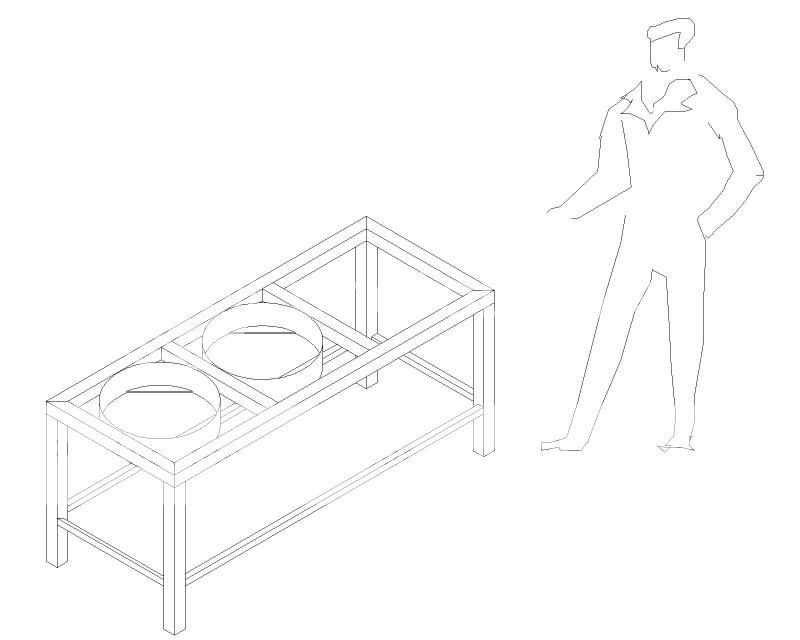

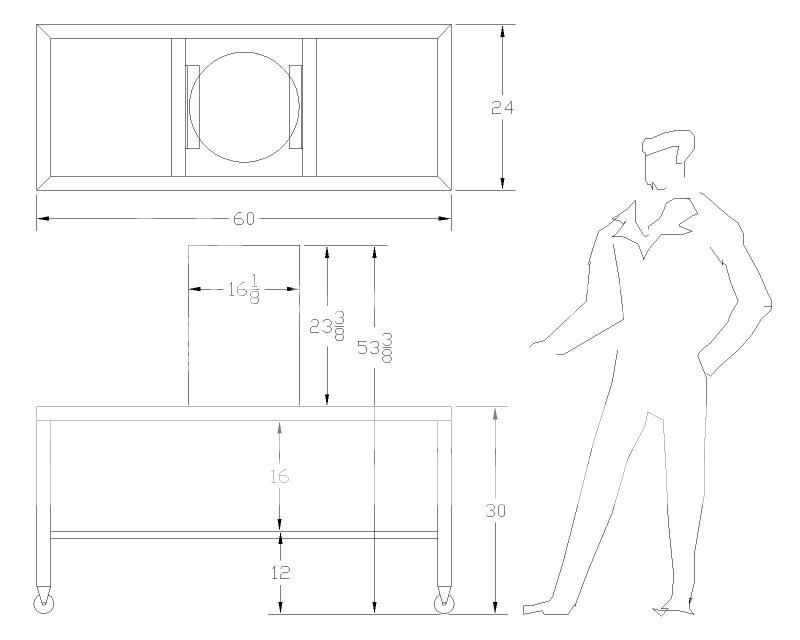

Besides staiinless and regular steel has anyone fabbed their rig out of aluminum? I picked up some 2"x2"x1/8" wall aluminum tube this weekend and plan on using it for my brutus like stand. The plan is to have wind shields plus a stainless angle ring or stainless angle legs for the kettles to rest on. None of the aluminum should be touched by the flame, but are there any other considerations with an aluminum stand? I won't be using gas rail, but just regular gas pipe and fittings for fuel supply.