discgolfin

Well-Known Member

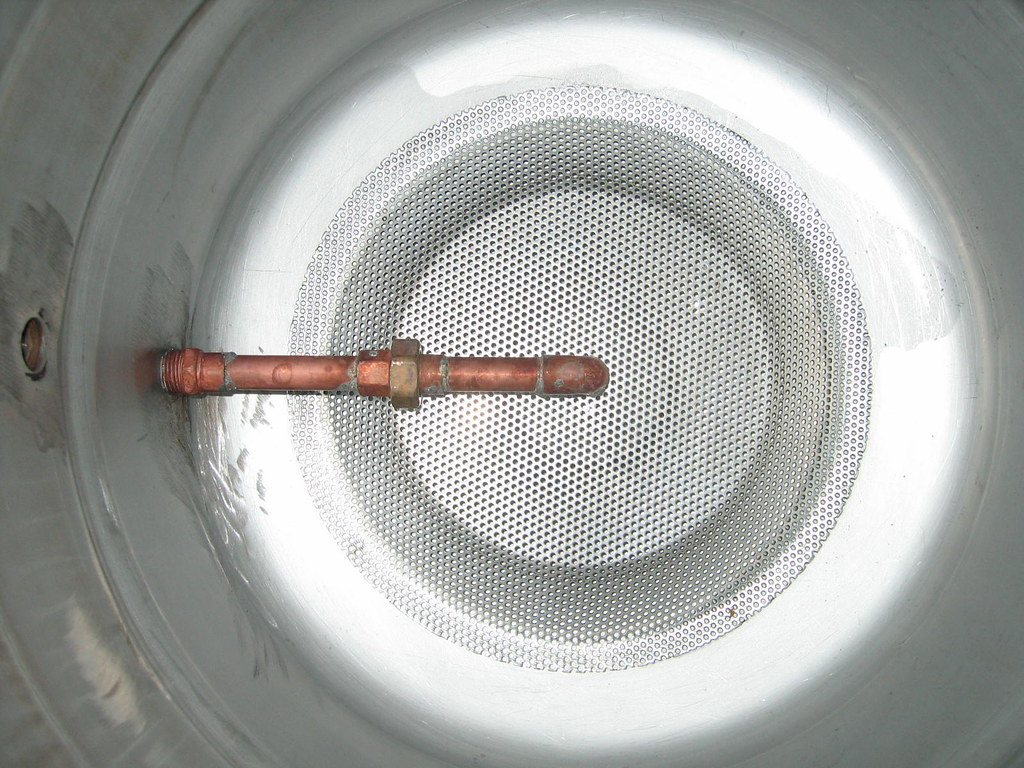

I currently have a 10 gallon cooler set up with this http://www.northernbrewer.com/brewi...ipment/false-bottoms/12-s-s-false-bottom.html false bottom.

I have a high temp hose connected to a nipple into the bulkead. This however casues the false bottom to raise up(grain to get under

). I want to connect a copper dip tube into this same false bottom some how..any thoughts? What parts I need to fit some 1/2 inch copper tubing into the false bottom and bulkead? I removed the middle peace and nipple so a compression fitting into the bulk head but what about into the middle of the false bottom?

help?

Jay

I have a high temp hose connected to a nipple into the bulkead. This however casues the false bottom to raise up(grain to get under

). I want to connect a copper dip tube into this same false bottom some how..any thoughts? What parts I need to fit some 1/2 inch copper tubing into the false bottom and bulkead? I removed the middle peace and nipple so a compression fitting into the bulk head but what about into the middle of the false bottom?

help?

Jay