GJOCONNELL

Well-Known Member

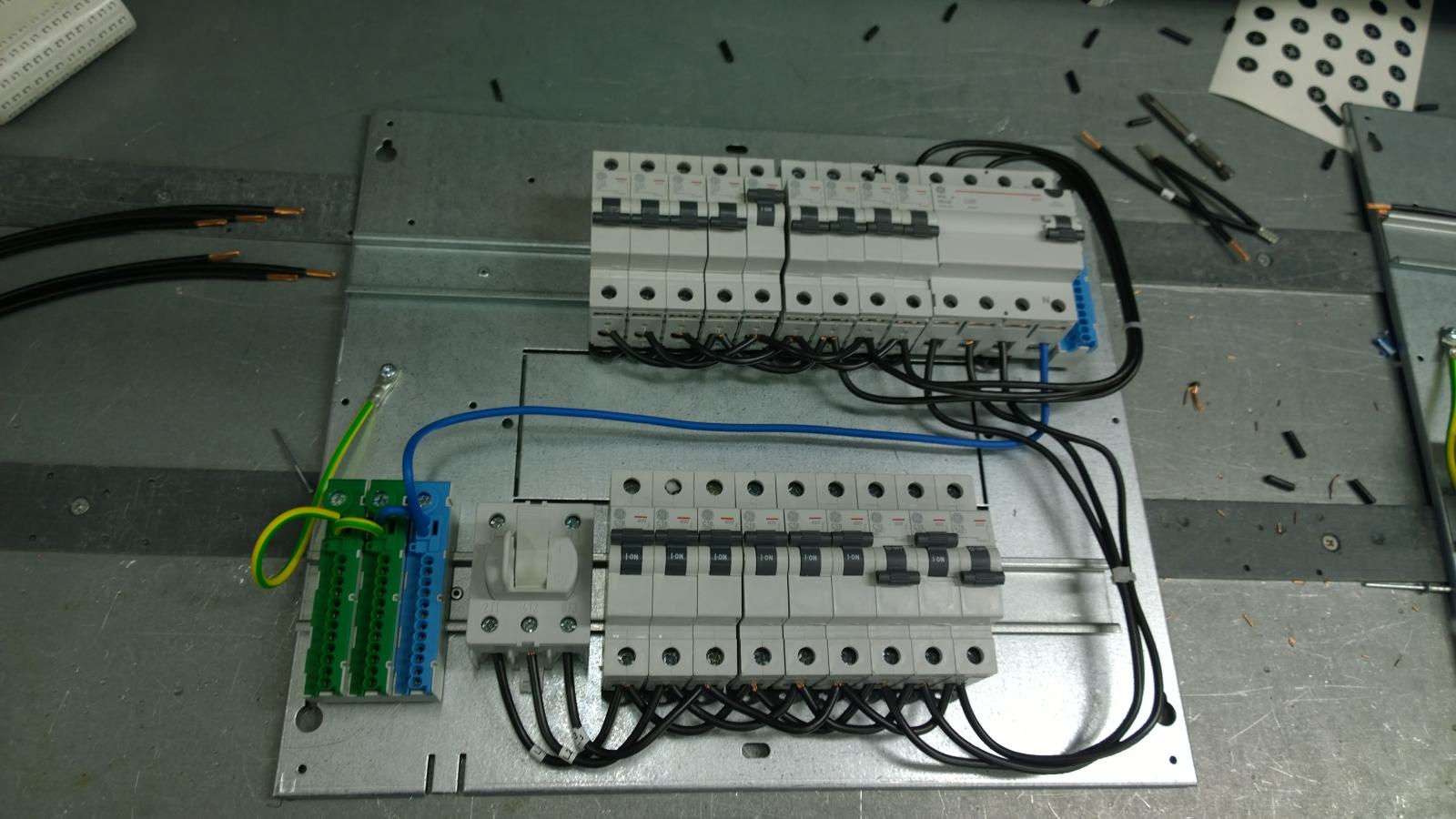

he said the contractor did a number of things incorrectly during our house remodel.

Anyway he recommends a new panel ($1,200 installed and fixing all the issues).

To get a 50 amp service to the back of the house would be $300 with cover and all that jazz.

So looking at $1,500 all in. He basically said I need to get the wiring issues fixed (wrong breakers for the panel, one breaker incorrectly wired, explorer why 50 amp breakers are being used when I have a gas range even though it is labeled cook top).

To get the wire to the shed would be another $200 because of the trenching but he said I could do it and save that money his trencher guy charges $30 a foot because his usual guys hate to trench so he outsources it.

Have to discuss the above with the wife but my guess is for now we will be fixing the panel to get it up to code and then down the line revisiting going all electric.....I hadn't broached the topic of the electric controller going to be another $800 or so for a 50 amp capable panel and I honestly don't have the kettles to utilize that setup.

I will probably just get a controller to use my existing 15 amp service and make it work with my gas setup and figure out how to get the RIMS (120v) dialed in.

Anyway he recommends a new panel ($1,200 installed and fixing all the issues).

To get a 50 amp service to the back of the house would be $300 with cover and all that jazz.

So looking at $1,500 all in. He basically said I need to get the wiring issues fixed (wrong breakers for the panel, one breaker incorrectly wired, explorer why 50 amp breakers are being used when I have a gas range even though it is labeled cook top).

To get the wire to the shed would be another $200 because of the trenching but he said I could do it and save that money his trencher guy charges $30 a foot because his usual guys hate to trench so he outsources it.

Have to discuss the above with the wife but my guess is for now we will be fixing the panel to get it up to code and then down the line revisiting going all electric.....I hadn't broached the topic of the electric controller going to be another $800 or so for a 50 amp capable panel and I honestly don't have the kettles to utilize that setup.

I will probably just get a controller to use my existing 15 amp service and make it work with my gas setup and figure out how to get the RIMS (120v) dialed in.