mandoman

Well-Known Member

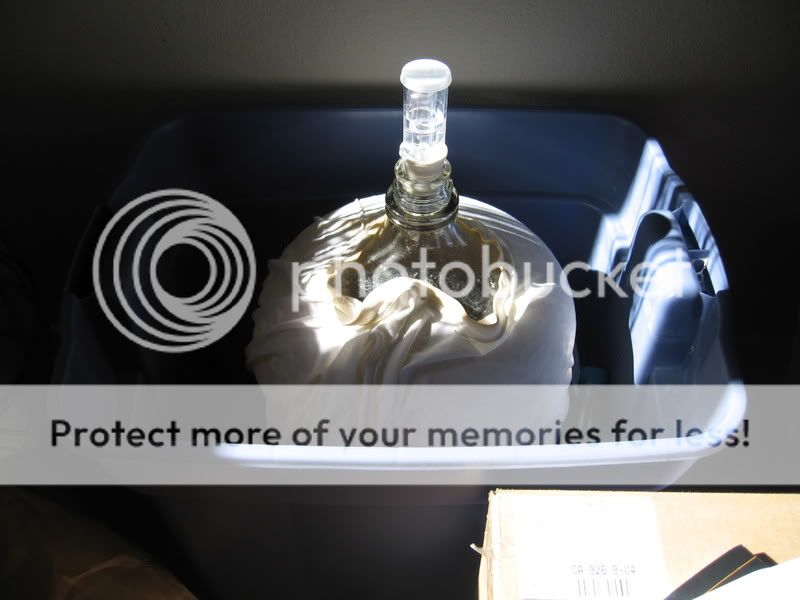

Wow, so I'm the type of person who needs to make mistakes before I really believe in the causes/warnings people give. Last night I tasted diacetyl in my pale ale that fermented for only 7 days in the primary cuz I was so hurried to get it to dry hops. My ferm temps were okay, right around 69 and steady and sanitation was good as far as I could tell. I'm guessing the diacetyl came from pulling it off the yeast early or not oxygenating enough (I shake but during chilling I use an aerator attachment thingy). Also, I had another pale ale that I bottled using the biermuncher-style homemade bottler that smelled like cardboard and tasted like paper - it was still okay but had gone downhill. I'm guessing this one was oxidized due to my amateur bottling abilities and method. I've used this bottling technique some and it works well in the short term but this beer had been bottled for almost 2 months.

So, do y'all think oxygenating my fermenter, fermenting 14 days, and either being more careful during bottling or getting a counterpressure filler would be my solutions?

cb

So, do y'all think oxygenating my fermenter, fermenting 14 days, and either being more careful during bottling or getting a counterpressure filler would be my solutions?

cb