I've done two batches so far through my plate chiller (full disclosure: I've only done two batches ever, but the plate chiller thing seemed so much better than ice baths/immersion that I went straight for it).

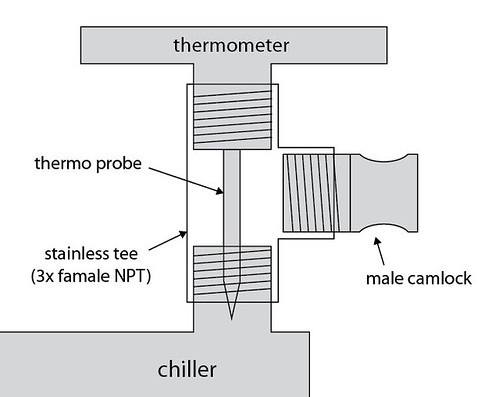

I ordered a tee and a thermometer for the cold side that I'm planning to "permanently" mount like this:

For context, here's the rest of my current setup. This is a temporary setup until I build my actual stand, so I'm not looking for aesthetic critique here

:

I have been cleaning my chiller and hoses, etc. after brewing by flushing with warm (120-140 degree) PBW solution and rinsing w/ fresh water. I also reverse the wort side fittings of the chiller for 5 minutes or so to make sure I dislodge any debris that may be stuck in the "riffles." Before brewing, I've been sanitizing by flushing with fresh water, then running a StarSan solution through the hoses, plump, and chiller and letting it sit there during the boil, after which I hook it up to the kettle and run wort through to push it out, then start filling the fermenter.

Your question has me wondering though -- is this thorough enough? I know there is some concern about having too many nooks and crannies within the system, but I was just planning to mount the thermometer as above and clean/sanitize the same way I've been doing it. I'm wondering about the reason to have it be camlock-disconnectable, or to immerse the entire chiller in sanitizer as someone stated above. Would be interested in thoughts from more experienced folks on this, since I'm very much making this up as I go along...