carrotmalt

Well-Known Member

My biggest complaint about my homebrew is its inability to retain hop flavor/aroma. Almost all of my beers are APAs, IPAs, or ambers, and they all focus primarily on the hops. I know these are supposed to be enjoyed young, but the flavor in mine fades in a matter of days. I keg and force carbonate, and the first few pints are almost always wonderful after the initial pint or two of yeast/sediment. Every time, I think I finally nailed the hops on a batch, only to sample it again a few days later to find a totally different beer. Still good, but just not very hoppy  It's like all of the hop oils are sitting at the bottom of the keg and they run out after 6 or 8 beers. I'm guessing those first few have a little more yeast and maybe hop residue or something that settles to the bottom, but they taste great.

It's like all of the hop oils are sitting at the bottom of the keg and they run out after 6 or 8 beers. I'm guessing those first few have a little more yeast and maybe hop residue or something that settles to the bottom, but they taste great.

I've tried moving to mostly late additions, steeping some for a bit after flameout before chilling, and dry hopping, but I don't know what else to do other than just using more hops. One thing to note is that I've been using the water chemistry primer for the last few batches and adding 1 tsp gypsum as well as 1 tsp calcium chloride per each 5 gallons of RO water. I'm wondering if maybe it needs more of those or some other minerals in order for the hops to shine. (should I try the Burton ale mix for these beers?) Anyway, I thought I'd post my latest recipe and see what you folks think.

This recipe turned out very smooth and I do like it. It's just not as hoppy as I was hoping. It's my first time using Simcoe so I was really anxious to taste the hops. Three days ago, I thought it might be one my best brews yet. After yesterday's sampler, it's just another plain Jane session beer.

Yeast: WLP001 w/ Starter

Mash: 154F

Actual OG: 1.050

Actual FG: 1.010

Primary for 3 weeks, cold crash 2 days, then racked to CO2 purged kegs.

12 Gallon batch:

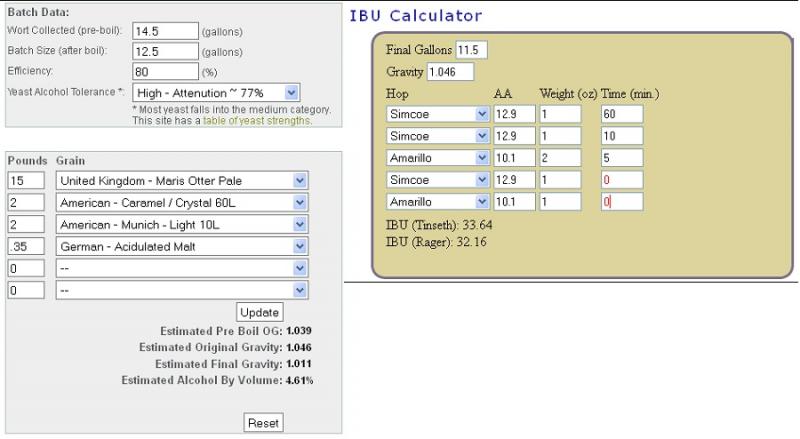

15# Marris Otter

2# Crystal 60L

2# Light Munich 10L

.35# Acidulated Malt

(all hops were pellets thrown directly in the boil/ no hop bags or spider)

1 oz Simcoe @ 60

1 oz Simcoe @ 10

2 oz Amarillo @ 5

1 oz Simcoe @ flameout

1 oz Amarillo @ flameout

1 oz Simcoe dryhop 6 days

1 oz Amarillo dryhop 6 days

Does this recipe sound like it should be hoppy in your opinion?

Anybody else using the primer as a guide that's putting out hoppy beers?

Any suggestions on hop or mineral additions?

I've tried moving to mostly late additions, steeping some for a bit after flameout before chilling, and dry hopping, but I don't know what else to do other than just using more hops. One thing to note is that I've been using the water chemistry primer for the last few batches and adding 1 tsp gypsum as well as 1 tsp calcium chloride per each 5 gallons of RO water. I'm wondering if maybe it needs more of those or some other minerals in order for the hops to shine. (should I try the Burton ale mix for these beers?) Anyway, I thought I'd post my latest recipe and see what you folks think.

This recipe turned out very smooth and I do like it. It's just not as hoppy as I was hoping. It's my first time using Simcoe so I was really anxious to taste the hops. Three days ago, I thought it might be one my best brews yet. After yesterday's sampler, it's just another plain Jane session beer.

Yeast: WLP001 w/ Starter

Mash: 154F

Actual OG: 1.050

Actual FG: 1.010

Primary for 3 weeks, cold crash 2 days, then racked to CO2 purged kegs.

12 Gallon batch:

15# Marris Otter

2# Crystal 60L

2# Light Munich 10L

.35# Acidulated Malt

(all hops were pellets thrown directly in the boil/ no hop bags or spider)

1 oz Simcoe @ 60

1 oz Simcoe @ 10

2 oz Amarillo @ 5

1 oz Simcoe @ flameout

1 oz Amarillo @ flameout

1 oz Simcoe dryhop 6 days

1 oz Amarillo dryhop 6 days

Does this recipe sound like it should be hoppy in your opinion?

Anybody else using the primer as a guide that's putting out hoppy beers?

Any suggestions on hop or mineral additions?