No, the sink isn't clogged. But I am planning to hard plumb my system tomorrow. I've been sketching all darn afternoon and I'm losing it so a little help would be greatly appreciated at this point.

I'm planning on adding an AUTOVENT. to solve any priming issues now that I have a RIMS setup. My question is, can I plumb the auto vent just like I'd plumb an air admittance valve or a vent for a sink, toilet etc.?

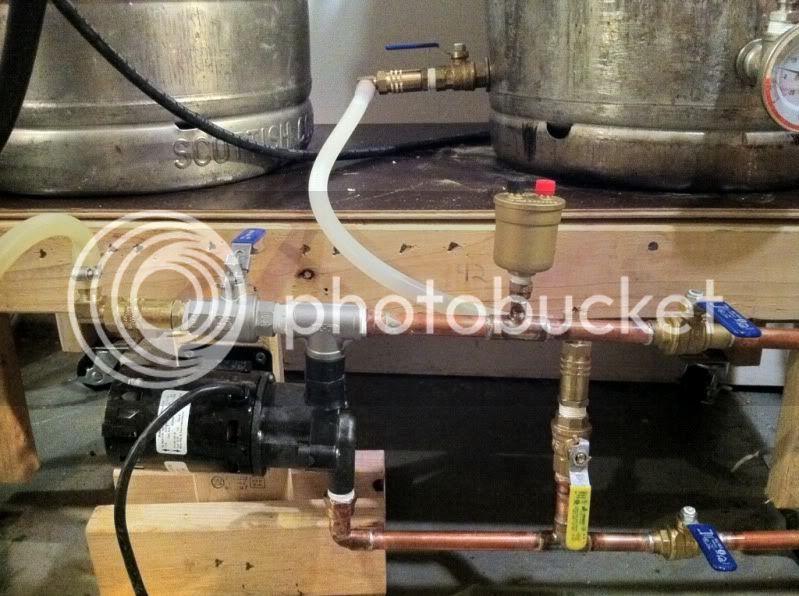

Like this... Just imagine the p trap is the pump, and the Autovent is behind the pump inlet. INSTEAD of the water feeding down the waste pipe, mine will hopefully flow up into the pump head. Or do I need to position the autovent behind the flow of liquid heading to my pump inlet?

I imagine the pressure issues created with water flowing down the waste pipe here are the same as those created with water going into the pump inlet. So can they be solved the same way?

Basically, I'd like to be able to send wort to my pump from a brew kettle on the left and the mash tun on the right. So liquid will feed the pump head from either side. That makes locating the auto vent kind of tricky.

So will putting the autovent on a tee behind the pump inlet work to allow flow from both sides to enter the pump inlet?

Thanks a lot for the help. Can't think straight anymore tonight. Cheers! Time for a homebrew.

Time for a homebrew.

I'm planning on adding an AUTOVENT. to solve any priming issues now that I have a RIMS setup. My question is, can I plumb the auto vent just like I'd plumb an air admittance valve or a vent for a sink, toilet etc.?

Like this... Just imagine the p trap is the pump, and the Autovent is behind the pump inlet. INSTEAD of the water feeding down the waste pipe, mine will hopefully flow up into the pump head. Or do I need to position the autovent behind the flow of liquid heading to my pump inlet?

I imagine the pressure issues created with water flowing down the waste pipe here are the same as those created with water going into the pump inlet. So can they be solved the same way?

Basically, I'd like to be able to send wort to my pump from a brew kettle on the left and the mash tun on the right. So liquid will feed the pump head from either side. That makes locating the auto vent kind of tricky.

So will putting the autovent on a tee behind the pump inlet work to allow flow from both sides to enter the pump inlet?

Thanks a lot for the help. Can't think straight anymore tonight. Cheers!

Time for a homebrew.

Time for a homebrew.