Desert_Sky

Since 1998

Hey since you are the man when it comes to gadgets, I have a question for you.

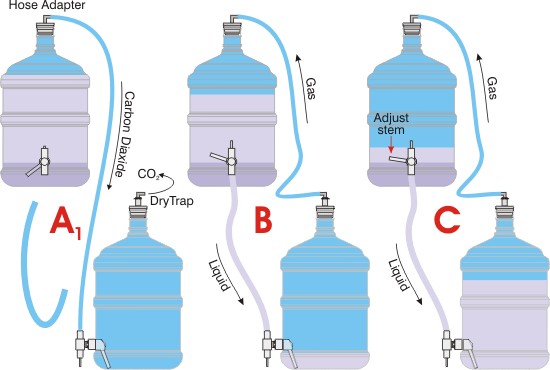

I was thinking about oxidation and such when transferring between carboys. Would it be hard to come up with some sort of CO2 gun? SOmething that allows you to use your gas in line from a corny fitting, but has a long tube to shoot CO2 into the bottom of the carboy. I was trying to come up with a easy way to do this. Im thinking something along the lines of a beer gun, but for CO2 only and then a racking cane end to reach the bottom of a 6.5. I would feel alot better about racking if I could have the carboy purged with CO2 before hand.

Clear as mud?

Or is something like this allready available?

I was thinking about oxidation and such when transferring between carboys. Would it be hard to come up with some sort of CO2 gun? SOmething that allows you to use your gas in line from a corny fitting, but has a long tube to shoot CO2 into the bottom of the carboy. I was trying to come up with a easy way to do this. Im thinking something along the lines of a beer gun, but for CO2 only and then a racking cane end to reach the bottom of a 6.5. I would feel alot better about racking if I could have the carboy purged with CO2 before hand.

Clear as mud?

Or is something like this allready available?