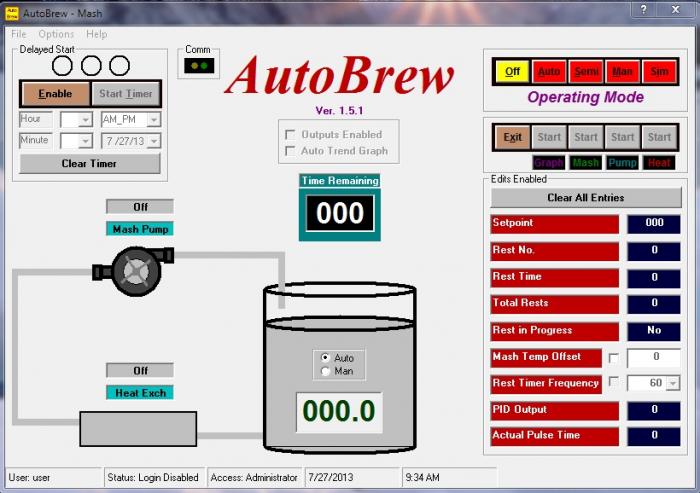

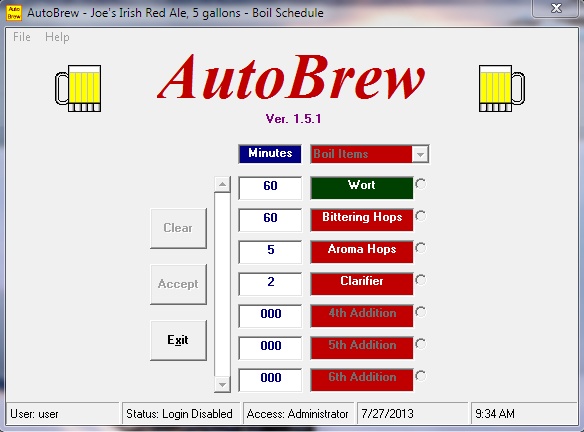

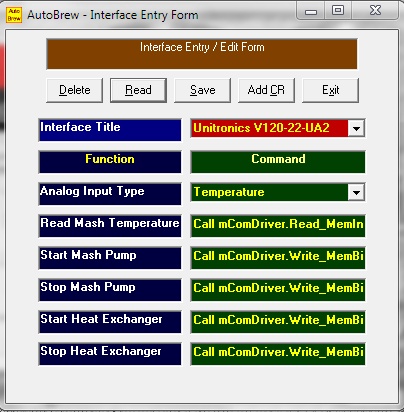

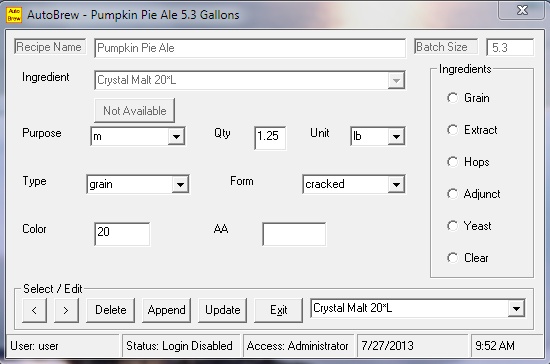

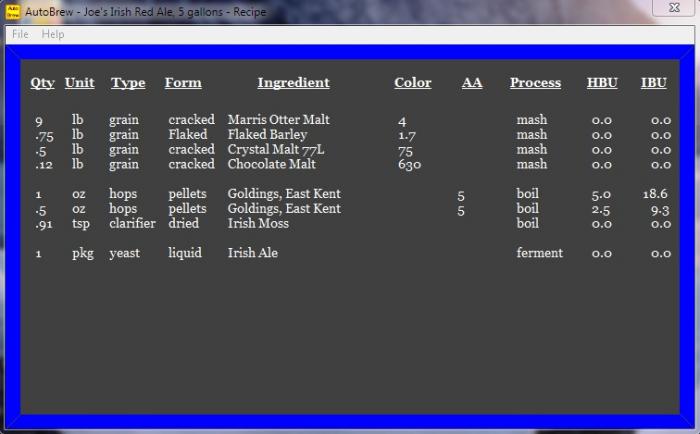

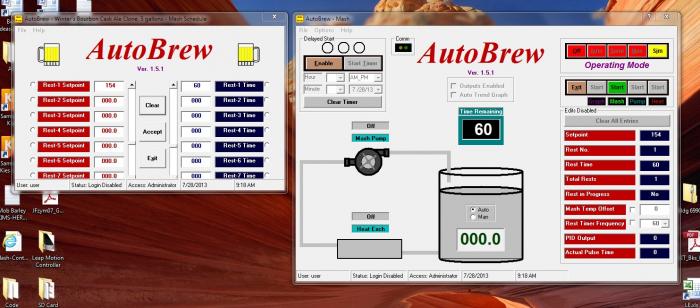

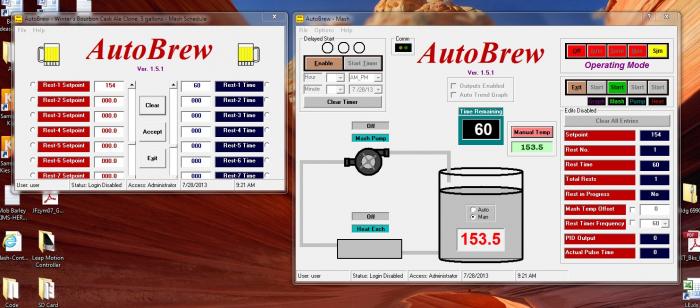

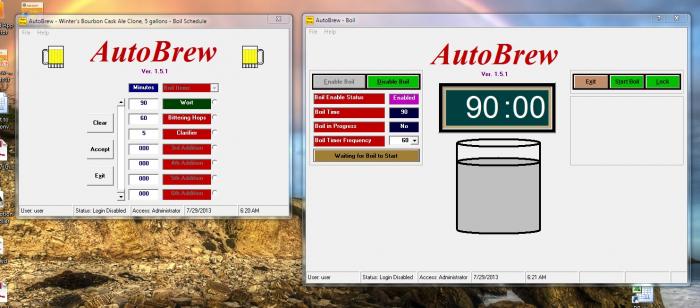

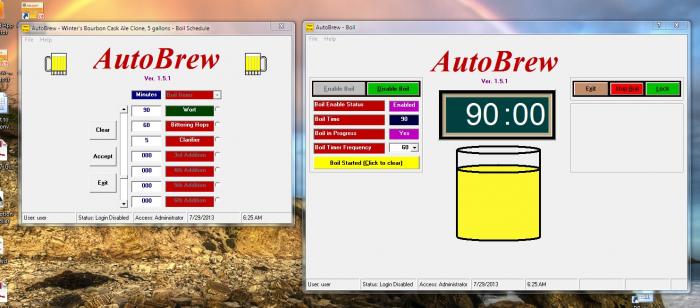

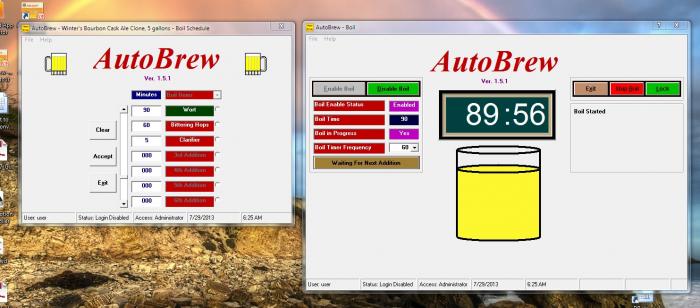

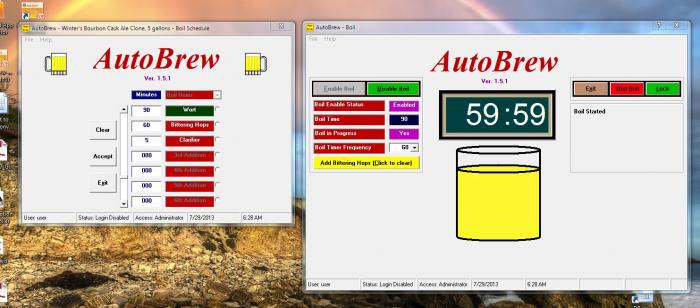

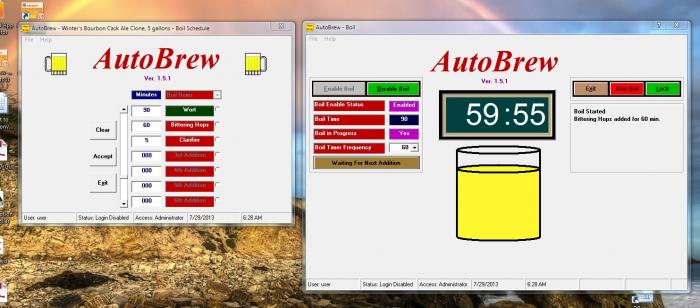

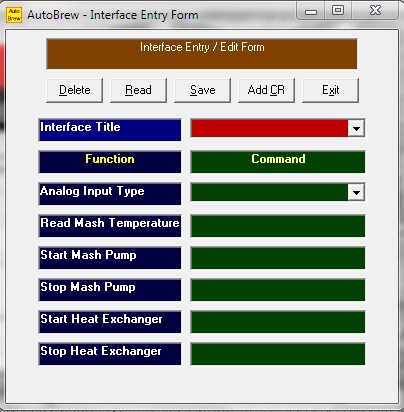

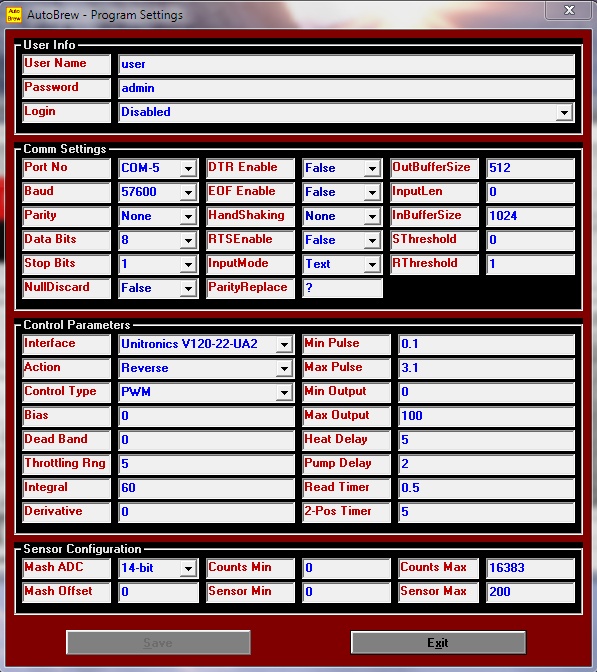

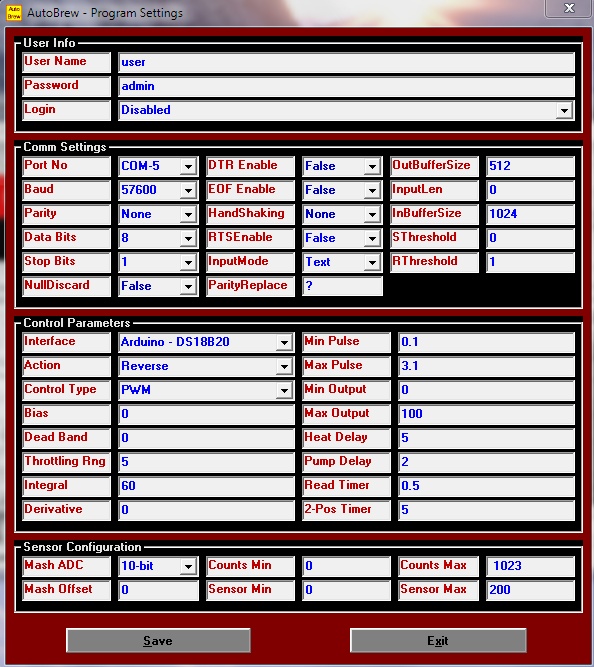

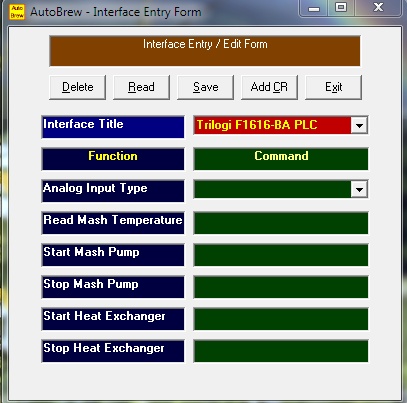

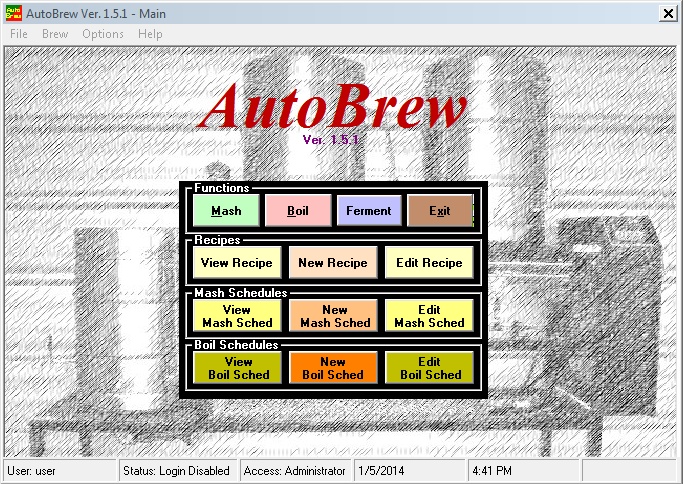

I started a project about five years ago and have had it substantially finished for a year now. What I ended up with is a software program that controls a mash pump and mash heater, reads the mash temperature and controls my RIMS. I wanted the program to be fairly universal so that it could be used with various microcontrollers and PLC's, so I wrote a process control class that allows my program to do the actual controlling while using the microcontroller/PLC as a simple I/O module. I am posting some screenshots here. This was used last Fall to brew an attempt at a Winter's Bourbon Cask Ale and the mash temperature controlled to +/- 0.2 degrees Fahrenheit with minimal loop tuning. My RIMS is a Sabco Brewmagic which necessitated my learning some ladder logic to configure the PLC to work as an I/O module instead of controller. I have also written a program for a Basic Stamp II and one for an Arduino to allow them to work with my program and both do work. The program is called AutoBrew for the time being and has too many functions for a short write-up. Perhaps I can do a You Tube video even though I'm not much of a narrator.