You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

purdman10

Well-Known Member

I also was a beta tester using a adafruit feather m0 wifi atwinc1500, with one-wire probes and propane. I had an old laptop laying around, and I can confirm that BruControl can run on XP with .Net 4.0, Win7 and Win10. I wanted more portability, so threw the GUI onto an Android tablet with the TeamViewer app, and use a network that only communicates with the software and hardware without internet access. This software is extremely open and configurable. I also mirror Augiedoggie's comment that Brundog has been very responsive to questions and sorting out any issues as we discovered them along the way. I also agree that he has been very proactive in adding more features and flexibility to the software as the beta updates have been progressing. BrunDog is passionate about brewing, and passionate to help people along the way.

I hope not to sound defensive, but you can do likewise with the button in BC. I didn't show them in the video, but there are user controls elements like a switch and a button. So for example, you would create a button element. Then you would write a script which would wait for the button to be pressed. Once it is, the script would continue and turn on the stuff you want it to, or start another script where that gets done.

The key here is you do everything in one place, rather than needing to edit the code for the control or the slave side, compile, re-run, etc.

thats nice to have kind of like the old days where you created a macro that does a bunch of stuff, I like it keep up th good work

augiedoggy

Well-Known Member

I got my second control panel set up for my fermenter control, I only have one beer in one conical I was starting to cold crash but the software is working as it should and brought it down to to the desired temp and held it there all night, for testing I only brought it down to 50 degrees and have it set so the chiller kicks back on at 52 and the heater kicks on at 48 and only after the temp is at that setpoint for 3 minutes but I will be tightening that up. I wanted to use the graph to get an idea of the amount of overshooting I might have. with the conical Im using at the moment I dont think I will have much since the cooling jacket is just 1/2" surgical rubber hose wrapped around the outside of the conical and its the least effective solution I've come up with. the 1.5" discharge hose would have brought my temps down much quicker like it does in my larger conical as well as the coolzone jacket I use on the 3rd larger conical.

The one wire sensor I connector to report my chiller temps appears to have a wiring short so I do not have that overlaying on any of the graphs. Also I was handling the other probes which is why the graphs so sudden variances.

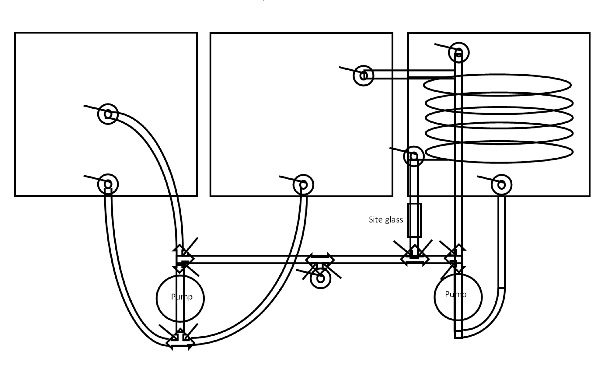

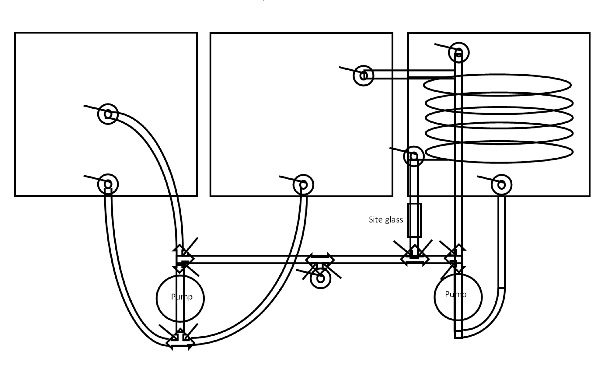

here are some pics Ive taken while setting up and moving things around.. the last one was how I had my brewing screeen setup for the last few brewing sessions.. again I havent done any automation/scripts yet but will be soon.

![IMG_20170408_191301184[1].jpg IMG_20170408_191301184[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339155-IMG-20170408-191301184-1-.jpg)

![IMG_20170409_090047560[1].jpg IMG_20170409_090047560[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339156-IMG-20170409-090047560-1-.jpg)

![IMG_20170409_085954393_HDR[1].jpg IMG_20170409_085954393_HDR[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339157-IMG-20170409-085954393-HDR-1-.jpg)

![IMG_20170409_090003247[1].jpg IMG_20170409_090003247[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339158-IMG-20170409-090003247-1-.jpg)

![IMG_20170216_152321946[1].jpg IMG_20170216_152321946[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339159-IMG-20170216-152321946-1-.jpg)

![IMG_20170216_152221170[1].jpg IMG_20170216_152221170[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339160-IMG-20170216-152221170-1-.jpg)

The one wire sensor I connector to report my chiller temps appears to have a wiring short so I do not have that overlaying on any of the graphs. Also I was handling the other probes which is why the graphs so sudden variances.

here are some pics Ive taken while setting up and moving things around.. the last one was how I had my brewing screeen setup for the last few brewing sessions.. again I havent done any automation/scripts yet but will be soon.

![IMG_20170408_191301184[1].jpg IMG_20170408_191301184[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339155-IMG-20170408-191301184-1-.jpg)

![IMG_20170409_090047560[1].jpg IMG_20170409_090047560[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339156-IMG-20170409-090047560-1-.jpg)

![IMG_20170409_085954393_HDR[1].jpg IMG_20170409_085954393_HDR[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339157-IMG-20170409-085954393-HDR-1-.jpg)

![IMG_20170409_090003247[1].jpg IMG_20170409_090003247[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339158-IMG-20170409-090003247-1-.jpg)

![IMG_20170216_152321946[1].jpg IMG_20170216_152321946[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339159-IMG-20170216-152321946-1-.jpg)

![IMG_20170216_152221170[1].jpg IMG_20170216_152221170[1].jpg](https://cdn.homebrewtalk.com/data/attach/339/339160-IMG-20170216-152221170-1-.jpg)

canmorebrewguy

Well-Known Member

- Joined

- Oct 5, 2015

- Messages

- 103

- Reaction score

- 15

Thanks guys. I actually did replace my BCS with this system. I used the same thermistor probes, relays, etc. so the upgrade path was fairly easy.

BTW, I need to give a big "Thank You" to @augiedoggy for being a contributing beta tester. He's actually done more brews than I and can probably give unbiased feedback.

I plan to do a brew video soon to show it in operation as well.

Hey Brundog,

I just finished my BCS 462 panel and stumbled upon this. Would switching to your Brucontrol set up be as easy as using the same wiring and just hooking up all of the inputs, outputs and temp probes? If it is I will be purchasing one ASAP!

Cheers,

Todd

So I have been looking into getting a RIMS setup, and building a controller, so the timing of this is very interesting! I have not purchasing anything on this, just research. So my question is what would you recommend purchasing for running this software for the controller box side of things? I do not have any PIDs, lights, switches, nothing yet. All I have is some 12 gauge wire, 16 gauge wire, tool box for controller box, some terminal strips, and Topsflo TD5 DC pump.

For now it would just be a RIMS controller, however I always keep my options open and the possibility of all electric, or even controlling propane burners is always a possibility. Also eventually I like the idea of setting up something to control temperature for fermentation.

For now it would just be a RIMS controller, however I always keep my options open and the possibility of all electric, or even controlling propane burners is always a possibility. Also eventually I like the idea of setting up something to control temperature for fermentation.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

Hey Brundog,

I just finished my BCS 462 panel and stumbled upon this. Would switching to your Brucontrol set up be as easy as using the same wiring and just hooking up all of the inputs, outputs and temp probes? If it is I will be purchasing one ASAP!

Cheers,

Todd

Hi @canmorebrewguy,

It is pretty straightforward but I would want to understand your I/O. The SSRs are direct swap. The relays likely are, assuming you are using 5V relays. Sensors are the same. The temperature probes need the front-end voltage divider and filter circuit. See the thermistor schematics here: http://brucontrol.com/wp-content/uploads/2017/03/BruControl-Thermistor-Schematic.pdf

That said, I built some boards to handle this. I can make one for you, which will make your temp probes plug & play.

PM me or contact me at the website if you want to discuss.

So I have been looking into getting a RIMS setup, and building a controller, so the timing of this is very interesting! I have not purchasing anything on this, just research. So my question is what would you recommend purchasing for running this software for the controller box side of things? I do not have any PIDs, lights, switches, nothing yet. All I have is some 12 gauge wire, 16 gauge wire, tool box for controller box, some terminal strips, and Topsflo TD5 DC pump.

For now it would just be a RIMS controller, however I always keep my options open and the possibility of all electric, or even controlling propane burners is always a possibility. Also eventually I like the idea of setting up something to control temperature for fermentation.

Right now building a controller is very DIY and requires some integration know-how. I want to make it easier, so my apologies more isn't on the site yet. I will be working on more complete schematics along with Bill of Materials for those builds as guidelines.

That said, I would recommend an Arduino MEGA2560, a screw shield to go with it (I like one like this (serial connection only): http://a.co/jaE5OsT but you can also get it without the DIN mount), a 12V power supply, SSRs (as many as needed to run your elements), a 12V relay board (like this one: http://a.co/270vJ0h). Temperature probes are up to you... 1-wire is easiest and only require direct connection and one resistor, thermistors are also easy but require some supporting components, and RTD are the most accurate but require some supporting amplifier boards.

Right now building a controller is very DIY and requires some integration know-how. I want to make it easier, so my apologies more isn't on the site yet. I will be working on more complete schematics along with Bill of Materials for those builds as guidelines.

That said, I would recommend an Arduino MEGA2560, a screw shield to go with it (I like one like this (serial connection only): http://a.co/jaE5OsT but you can also get it without the DIN mount), a 12V power supply, SSRs (as many as needed to run your elements), a 12V relay board (like this one: http://a.co/270vJ0h). Temperature probes are up to you... 1-wire is easiest and only require direct connection and one resistor, thermistors are also easy but require some supporting components, and RTD are the most accurate but require some supporting amplifier boards.

Thanks for the information. Understand completely that that the controller is on me! The information you provided will help me look into this side of things more. Not at the point yet to move forward, but I like to research the hell out of new things, so this gives me what I need to move forward on more research.

I am comfortable with doing the DIY controller. I completely understand that right now your main focus has been testing and development of the software. I am sure that as this progresses more, time for that type of info will happen. I have been looking at the info on building RIMS controllers now for probably 2 or 3 months. I like the idea of the software though instead of PID, and having the data post brew to review and for documentation!

I also understand that there is only so much that you can provide on the controller side of things, as there are so many variables as far as that goes. I don't post a lot on the forum, but I am on it a lot. I have seen that you are very active with the community and providing help \ guidance, so I am confident in purchasing this relatively young software because of that. I am leaning towards this setup instead of the PID, but I am probably still a couple months away from moving an any solution.

on th rtd this is what keeps coming up for me am i right?

MAX31865

https://www.adafruit.com/product/33...Nh3BoV2DgvFGZQWESnf-G_VkAf8W6nSYprBoCzkjw_wcB

MAX31865

https://www.adafruit.com/product/33...Nh3BoV2DgvFGZQWESnf-G_VkAf8W6nSYprBoCzkjw_wcB

on th rtd this is what keeps coming up for me am i right?

MAX31865

https://www.adafruit.com/product/33...Nh3BoV2DgvFGZQWESnf-G_VkAf8W6nSYprBoCzkjw_wcB

That's the one! You can get similar boards off ebay too. Augiedoggy used those with success.

augiedoggy

Well-Known Member

on th rtd this is what keeps coming up for me am i right?

MAX31865

https://www.adafruit.com/product/33...Nh3BoV2DgvFGZQWESnf-G_VkAf8W6nSYprBoCzkjw_wcB

I used 4 of these.. they are working well. http://www.ebay.com/itm/Arduino-MAX...813391?hash=item4d50119d0f:g:aoQAAOSw-0xYR9X3

these work as well.. http://www.ebay.com/itm/17238797769...49&var=471216740806&ssPageName=STRK:MEBIDX:IT I bought one of these to wire it in but a resister is all thats needed.

http://www.ebay.com/itm/262732761967?_trksid=p2057872.m2749.l2649&ssPageName=STRK:MEBIDX:IT

As far as the relay boards, I've tried a few now with my two control panels and this one is my favorite. http://www.ebay.com/itm/16-Channel-...543482?hash=item3389ff527a:g:eHwAAMXQ855Rw7uH

The reason being is I can feed it 12v and it actually regulates it down to 5v to power anything else I need 5v for so im not running everything off the regulator in the MEGA. The relay coil power is completely independent of the MEGA as well (I feed both this board and my MEGA 12v so the output signal to the relay board is 5v instead of the 3.3v it would be if I was just powering the Mega wih the USB or 5v. and of course the relay board is "active high trigger" which works well with the software although Brundog is actually updating the software to work with either active low or high boards.

OK, after some initial review of piecing together the boards necessary, a lot more research and some guides would actually be very useful! But I know getting the software out there, and documented is much more important!

augiedoggy

Well-Known Member

OK, after some initial review of piecing together the boards necessary, a lot more research and some guides would actually be very useful! But I know getting the software out there, and documented is much more important!

I felt the same way when going from pids and analog switches to brucontrol and an arduino.. I believe the manual for Brucontrol does go over the hardware although since its opensource there are variations from different suppliers.

If it helps...

I have built 2 panels now and I didnt use a shield for either although it might have made things more convenient. I just used the following besides what I posted above (again everyones needs/wants might be different and I reused the rtd and stc probes I already had plus added the 1 wire just because I wanted to see how well it worked and I needed one more temp probe to control my chiller reserve tank temps.)

This to control the speed of my DC24v pumps (not useful unless you have dc pumps or motors you want to control)

http://www.ebay.com/itm/2Pcs-IRF520...erry-pi-New-/221516832245?hash=item33936e9df5

I bought these to keep them cool

http://www.ebay.com/itm/10pcs-TO-22...FET-New-3YE-/272401709571?hash=item3f6c683a03

These to connect the devices to my arduino.

http://www.ebay.com/itm/40PCS-Dupon...o-extension-/281674937470?hash=item419522747e

The arduino of course..

http://www.ebay.com/itm/MEGA-2560-R...for-Arduino-/221774825267?hash=item33a2cf4733

I used one of these for my BK and HLT http://www.ebay.com/itm/Dual-Solid-...dom-D2440DE-/300957098426?hash=item461270e1ba

obviously there are better choices but this was easy to wire with the dupont cables and works well.

(I'm currently using an old fotek clone SSR I had laying around for my rims.)

The rest was your standard contcators and a few 22mm indicators as well as a emergency estop switch and a volt/amp watt meter and other stuff you would use on any panel analog or microcontroller/software based.

were should we report errors or feed back here or the website, i might have a small bug

You can report here for now.

ok no a big issue but I had the app open on my pc while still using it and switching back and fourth, the main issue i think is I have a 720p monitor and the post buttons were hiding under the main bar, I think I read something about this in the manual but I went to change the settings to hide the bar and the courser turned to resize arrows and wouldn't let me select anything, eventually it timed out after a bit and was able to hit ctr alt del and get out of it to use my pc

Thanks to the mods for working with me to get this thread back online. Good people doing the right thing for the forum.

FYI I posted a video on the website discussing some of the basic differences in the types of micro-controller interfaces and how to set one up. It is under Build... Videos.

FYI I posted a video on the website discussing some of the basic differences in the types of micro-controller interfaces and how to set one up. It is under Build... Videos.

Thanks to the mods for working with me to get this thread back online. Good people doing the right thing for the forum.

FYI I posted a video on the website discussing some of the basic differences in the types of micro-controller interfaces and how to set one up. It is under Build... Videos.

Thanks for the video, it helped me understand a little more about the different devices. Look forward to some more on adding additional items to the MEGA!

Great to see this thread back online!

Any plans for a Mac and/or iOS version or support for Raspberry Pi?

Our original project scope included a plan to compile to run on RPI hardware. As we developed we realized some of the underpinnings would not run under Mono.Net so the path to run under Linux was blocked as far as I know. I know Windows has its challenges but I believe in terms or reliability, it's much better suited to automation control than RPI. BC is meant to be a platform which runs all the time, so a Windows install makes sense from that perspective, but we understand less expensive or other hardware is preferential to many. We hope the upcoming web server inclusion will make it accessible to more hardwares like tablets etc.

As far as native Mac I would have to research it. Thanks for the inquiry!

As far as native Mac I would have to research it. Thanks for the inquiry!

Sweet! This would be my only hold up long term since it'd be ideal to just plug in my laptop whenever I brew (without having to dual boot)![emoji482]

Im having trouble finding a decent price on a float switch, where are you guys getting yours?

What type of switch are you looking for? I see basic stainless floats on Amazon for less than $10. Duckbill types a few $ more. These require a hole in your vessel.

I previously used capacitive sight glass sensors on both my MT and BK. They are great in that they can be moved up and down the sight glass, so are adjustable, but they are certainly more expensive. I am going to sell these, but they will be more than above, are 24V NPN sensors so need some integration depending on your controller, and you need a sight glass.

Alternatively, analog pressure sensors are inexpensive on the sensor side ($15) but you only need one per vessel and need a controller which can read them. A simple analog switch could do the trick. You could mount them separately but you could also tee one into your vessel output as long as you turn the flow off when reading it. Anyway, multiple options!

I previously used capacitive sight glass sensors on both my MT and BK. They are great in that they can be moved up and down the sight glass, so are adjustable, but they are certainly more expensive. I am going to sell these, but they will be more than above, are 24V NPN sensors so need some integration depending on your controller, and you need a sight glass.

Alternatively, analog pressure sensors are inexpensive on the sensor side ($15) but you only need one per vessel and need a controller which can read them. A simple analog switch could do the trick. You could mount them separately but you could also tee one into your vessel output as long as you turn the flow off when reading it. Anyway, multiple options!

looking for a cant fire the element dry switch

OK, then a simple duckbill float right above the element volume? Needs a hole in the vessel. You can directly wire inline with your SSR for a hardware solution.Something like: https://www.amazon.com/dp/B00AKXAUKC/?tag=skimlinks_replacement-20 or http://www.ebay.com/itm/USA-Stainle...evel-Sensor-Liquid-Float-Switch-/291770285524

Around $10... is that too much?

Around $10... is that too much?

Last edited by a moderator:

thats weird every one I searched for like that was $160 for high heat

The ebay one I linked says good to 125 C. Hey - I just saved you a bunch of money!

you bet thanks

another issue Ill be facing when I come to it is when I try to make my automated system just like i have it now with 5 - 3 way valves, 1 L and 4 T

Similar threads

- Replies

- 45

- Views

- 6K

- Replies

- 29

- Views

- 7K

- Replies

- 51

- Views

- 10K