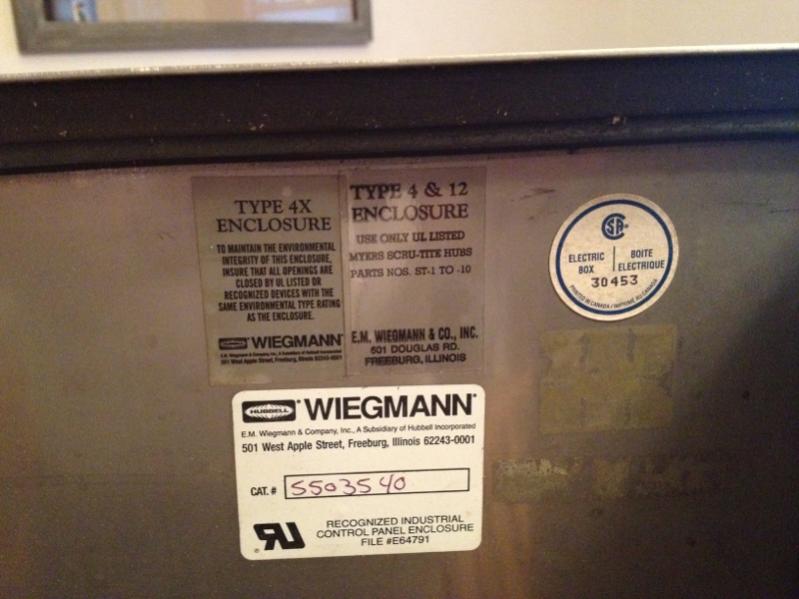

It looks like I will be able to get my hands on a few used 20" x 16" x 8" stainless NEMA 4 (Stainless may make them 4x) enclosures. I am planning an electric brewery build but am not as controls savvy as I would like to be. I also don't have the tools to punch the panel.

Would anyone be interested (particularly if you're in the Denver area) in helping out or putting together a panel in exchange for one or two of the stainless enclosures?

I'm not quite sure on the timeframe for my build but thought I would gauge whether there was any interest now.

-Kevin

Would anyone be interested (particularly if you're in the Denver area) in helping out or putting together a panel in exchange for one or two of the stainless enclosures?

I'm not quite sure on the timeframe for my build but thought I would gauge whether there was any interest now.

-Kevin