doctorsbro

Well-Known Member

I have been doing alot of research on bre stand designs and i have finalized the design. This week i will be cutting and forming all of the parts for the top. I will be using .105(12 gauge) 316 stainless sheet for all of the parts for the top. I will be bending them at work on a cnc press brake so they will be very precise and easy to fit when i weld it all together this weekend. The legs and frame will be made with 1.5"x1.5"x .125"(11 gauge) wall 304 stainless tubing. the front panel is sitting at a machine shop in town to be laser cut to cut the letters out, if its not done by thursday im going to go pick it up and just form the part and then etch the letters into the panel after its polished via a vinyl sticker with letter cutouts and sandblasting creating a textured surface where the letters are.

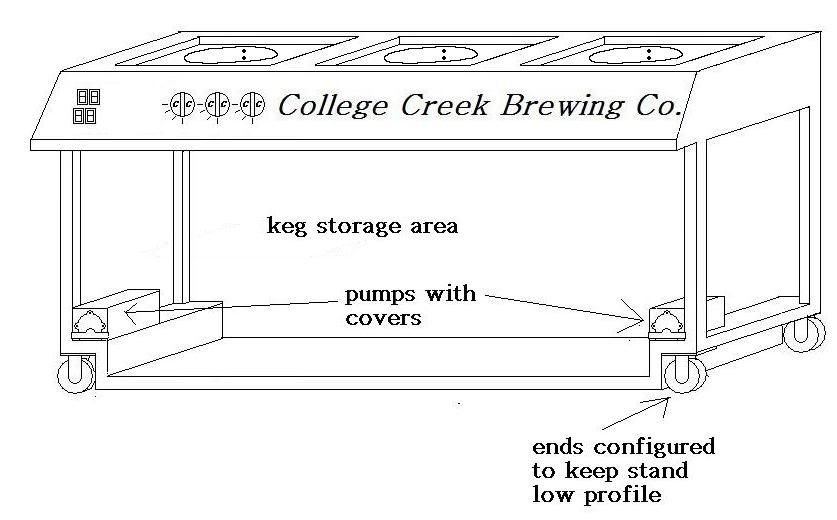

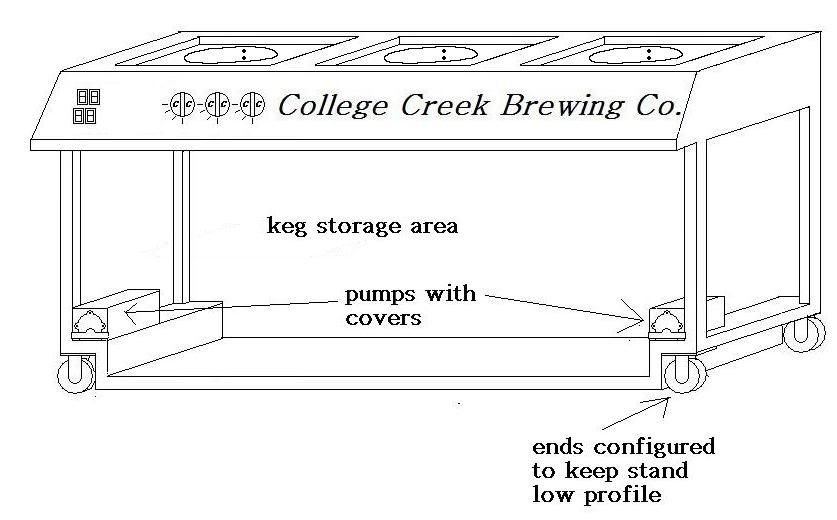

I have never brewed any beer in my life but have come very interested in the process, my brother is the one that brews and im the one that fabricates so i guess all works out, brewstand for him.... beer for me! Well heres a quick sketch in paintbrush of my design, the burners will have polished stainless grates filling the areas where the keggles will sit. Let me know what you think, i will be posting up more pictures all week.

I have never brewed any beer in my life but have come very interested in the process, my brother is the one that brews and im the one that fabricates so i guess all works out, brewstand for him.... beer for me! Well heres a quick sketch in paintbrush of my design, the burners will have polished stainless grates filling the areas where the keggles will sit. Let me know what you think, i will be posting up more pictures all week.

I have a Ph.D. in chemistry but no fabrication skills, so this build wouldn't be possible without Doctorsbro. Doctorsbro is the fabricator and I am the brewer, so I guess it works out okay. I've already promised to keep my brother supplied with beer in exchange for his work on this project.

I have a Ph.D. in chemistry but no fabrication skills, so this build wouldn't be possible without Doctorsbro. Doctorsbro is the fabricator and I am the brewer, so I guess it works out okay. I've already promised to keep my brother supplied with beer in exchange for his work on this project.