cherbhy

Well-Known Member

- Joined

- Oct 29, 2013

- Messages

- 94

- Reaction score

- 1

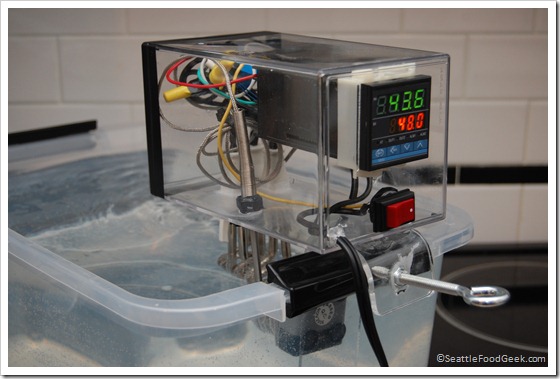

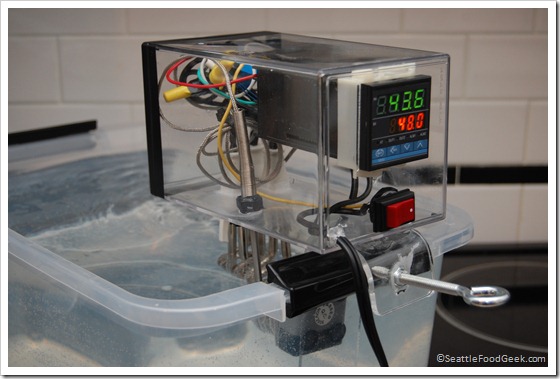

Before I built my mash tun, I had bought all the materials to build this DIY sous vide machine: link here.

Now, I'm thinking that I might as well find a way to separate the PID, SSR, and other electrical components from the heating coils. This way, I could mount the heaters inside the mash tun while keeping the PID on the exterior and maintain exact temperatures during the mash (or using plain water when cooking sous vide). This could prove useful not only for maintaining temperatures, but also for multi-step mashing.

The sous vide design also makes use of a 79 gph aquarium pump to circulate the water and ensure even heating throughout the vessel. I'm a little unsure of whether this would be useful for mashing. Thoughts?

So here's my question(s): Does anyone foresee problems with using heating coils in a MLT?

Does anyone have advice for mounting the three coils between the walls of the cooler? I'd like them to be removable for cleaning and mashing out/sparging.

Thanks in advance!

Now, I'm thinking that I might as well find a way to separate the PID, SSR, and other electrical components from the heating coils. This way, I could mount the heaters inside the mash tun while keeping the PID on the exterior and maintain exact temperatures during the mash (or using plain water when cooking sous vide). This could prove useful not only for maintaining temperatures, but also for multi-step mashing.

The sous vide design also makes use of a 79 gph aquarium pump to circulate the water and ensure even heating throughout the vessel. I'm a little unsure of whether this would be useful for mashing. Thoughts?

So here's my question(s): Does anyone foresee problems with using heating coils in a MLT?

Does anyone have advice for mounting the three coils between the walls of the cooler? I'd like them to be removable for cleaning and mashing out/sparging.

Thanks in advance!