Navy_Brewer

Member

- Joined

- Sep 30, 2006

- Messages

- 18

- Reaction score

- 2

I have been lurking for a while and have decided to take the plunge shifting to electric brewing. I am setting up an electric BIAB based in the 44 Qt Bayou Classic Pot. Seems to be perfect for my batch size (5 gal into keg) and I have made several great beers so far using it on a propane burner. I am looking at a 240VAC 5500 watt element as I have little patience and may want to move to 10 gallon batches some day.

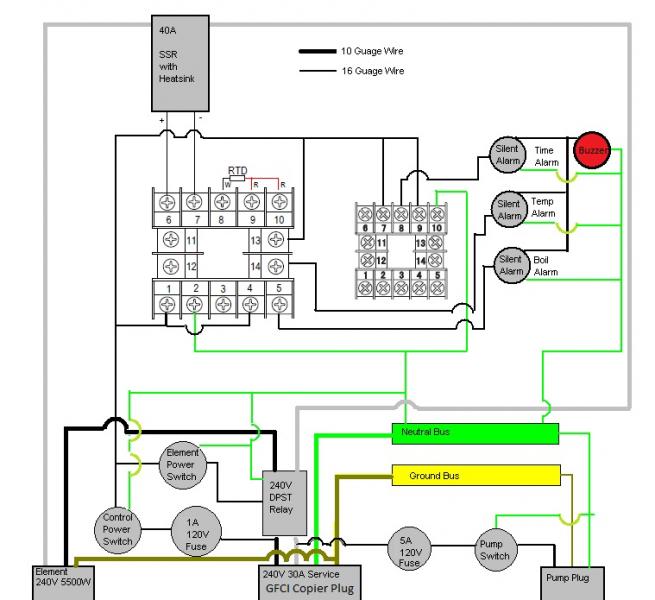

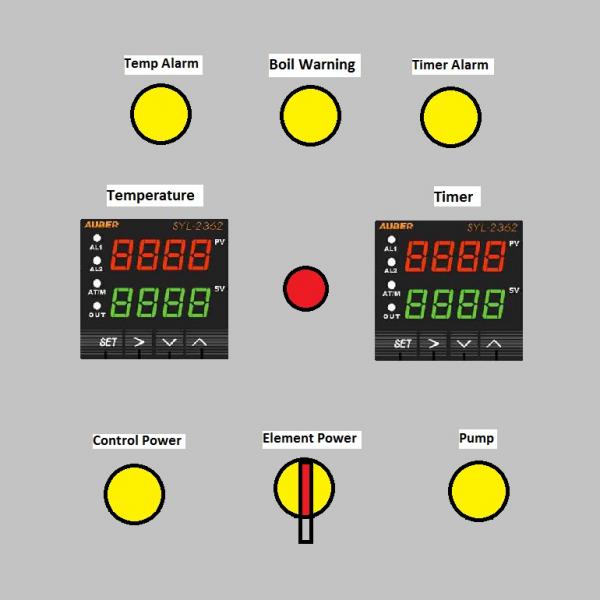

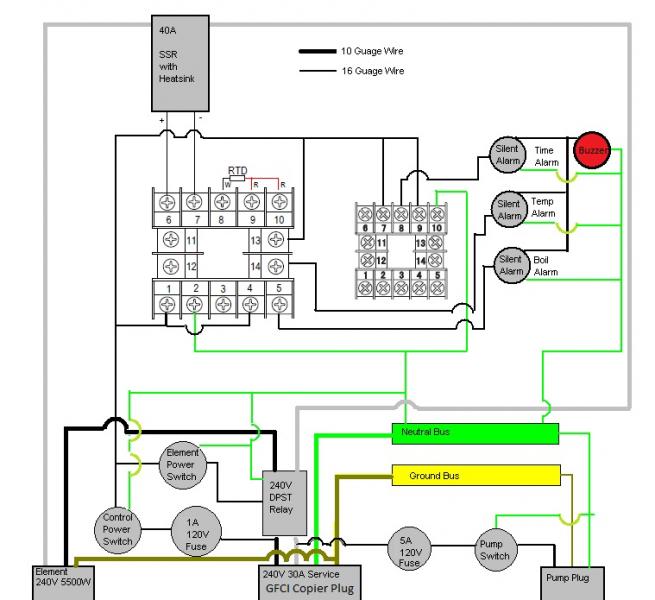

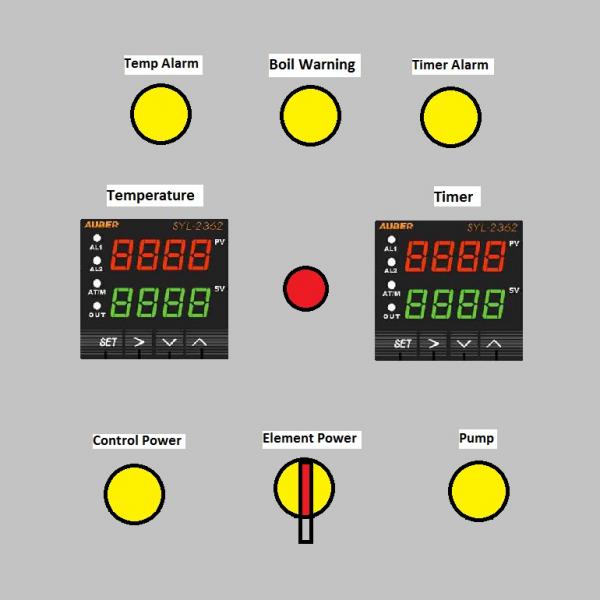

I have enclosed my wiring diagram and my control panel layout (8x8x6 conduit box from Home Depot) for a sanity check. I may use a .50 cal ammo can instead for the control panel but I have not yet decided or procured one from work.

I will try to document as much of the build as possible for those that are interested in a mid level, BIAB set up.

Thanks and I look forward to contributing here.

I have enclosed my wiring diagram and my control panel layout (8x8x6 conduit box from Home Depot) for a sanity check. I may use a .50 cal ammo can instead for the control panel but I have not yet decided or procured one from work.

I will try to document as much of the build as possible for those that are interested in a mid level, BIAB set up.

Thanks and I look forward to contributing here.