thadeus_d3

Well-Known Member

Brewed a 10 gallon batch today. I'm so excited to try it in a month or so.

Exciting news! I spent some time this past weekend with a guy who was formerly a brewer for Mac & Jack's. Since he no longer works there he was more than willing to share information about M & J's. Here are some of the things I learned:

OG = 1.054

Grainbill: Pale malt, Munich, Crystal 120, and Wheat (hence the cloudiness)

Hops: Bittering - Cascade 60 mins, Aroma - Mt Hood (Last 5 Mins), Dry - Cascade

They also add something called Allfloc. Not too sure what this is or exactly what it does.

He couldn't tell me anything specific about their yeast other than it is proprietary and they harvest from their kegs to keep it going. He agreed with what I have always thought - the yeast is probably the most important ingredient. The nice thing is they don't filter so it is fairly easy to harvest yeast from a keg or growler (if you're in the Great Northwest).

Since my last batch was fairly close I can't wait to tweek my recipe and try again.

Cheers,

Dwight

One thing I forgot to mention, FG = 1.016. They check the gravity hourly once it gets under 1.020 and when it hits 16 they quickly chill it to 35F to stop the fermentation.

Sorry for quoting a post from 4 years ago, but I had a question on this. I've always been told to let the yeast clean itself up after it ferments. Will crashing before it cleans itself up lead to any off flavors?

This is basically what I changed my clone to so we will see. I haven't had this in 5+ years. I only remember the Cascade dry hop.

I read the 2-row for Mac & Jack's is locally sourced. I bought something from Montana. I went with a pound of 120L and switched the carapils to white wheat malt. I'm doing Cascade to bitter and an ounce of Mt. Hood at five minutes. Then the Cascade dry hop. I went with Wyeast 1968 for the yeast.

Hopefully my brother that used to live in Seattle likes it. I think it will work. I'll try not to say anything until after the first one.

Brewcat, will you share your recipe?

Sorry for quoting a post from 4 years ago, but I had a question on this. I've always been told to let the yeast clean itself up after it ferments. Will crashing before it cleans itself up lead to any off flavors?

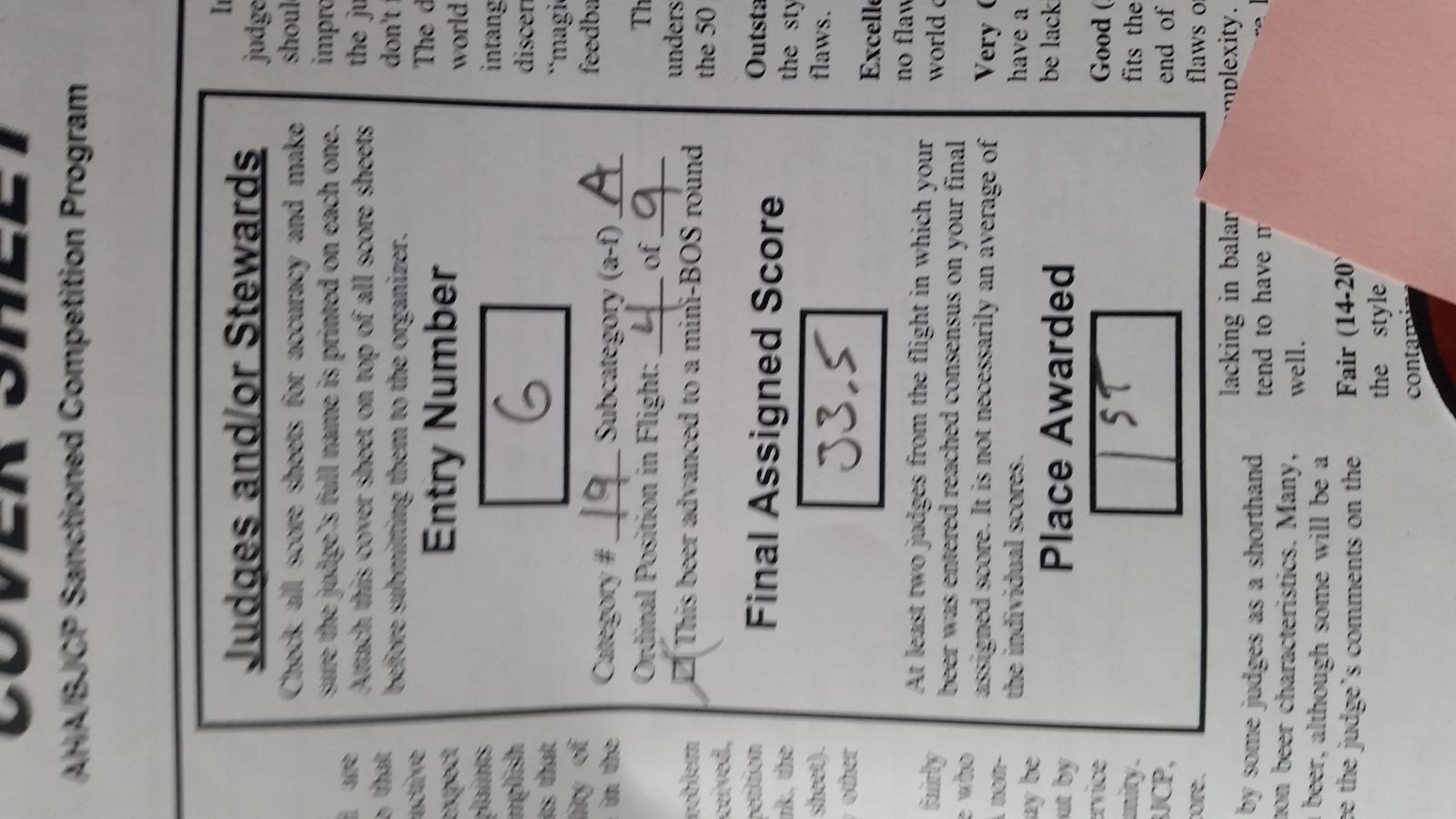

Just took a 1st with this...

Congrats Red, that's awesome! Did you use ohiodad's recipe as-is from the first post of this thread, or Biggben's tweaks to use 55L instead of 80L and 1968 London ESB yeast? Something else? I'm planning on brewing this next weekend.

I used Ohio dad's version but with 1968 yeast, and I used 1oz whole leaf cascade and .5 oz pellets.....(just cause i needed to use the whole leafs) for dry hop.

Here is round 2 for me on this beer. This is the first time I've messed with water chem as well, and my efficiency went up. I'm assuming because of hitting my pH. I forgot to buy mt hood hops, and only had an ounce left, so I used amarillo as my late addition. This batch smells incredible, and color is spot on. Can't wait to pour a glass on this.

FYI this is a 13 gal batch. Hit 1.062 SG, was shooting for 1.057. Also might tinker with the dry hop and add Amarillo with the Cascade. We'll see.

12.5 lb 2-Row

12.5 lb Maris Otter

3 lb Crystal 80L

3 lb Munich 10L

2 lb Wheat

1 lb Acidulated Malt

34 lb Total

Hops

3.5 oz Cascade 60 min

2.52 oz Amarillo 5 min

1 oz Mount Hood 5 min

2.52 oz Cascade Dry Hop

.....but was missing something. We'll see if it's the yeast in about two months.

definitely the yeast!

I brewed the extract version of this for my first batch back in 2008. It became my go-to beer and everyone enjoyed it. I used the BYO recipe. I've only brewed sporatically over the last 5 years or so (living in Florida makes brewing a pain during the summer - especially when you chiller water comes out of the tap a 90 degrees!) In any case I've moved to Germany and I'm getting back into brewing more-or-less 'full time'.

I'm moving into all-grain brewing and I'm eager to try this recipe. Thanks to everyone over the last 9 years who has contributed to this thread. Now to the point of my post.

The last time I had Mac and Jacks - which was about 2 years ago - I seemed to detect a very subtle chocolate flavor. Was it just my palate? Has anyone thrown any chocolate malt in their recipe? I'm tempted to do so just to see what happens.

Hey Brewcat and Dwightr8,

This has been a really interesting read. Just curious how your guys last batches came out. I used to love this beer and Seattle, so just looking to make something similar to that taste. Does the the 120L taste better than the 80L or just what they used at Mac and Jacks?