Holden Caulfield

Well-Known Member

- Joined

- Apr 21, 2020

- Messages

- 318

- Reaction score

- 337

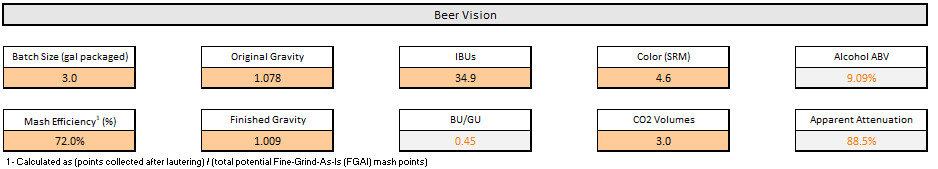

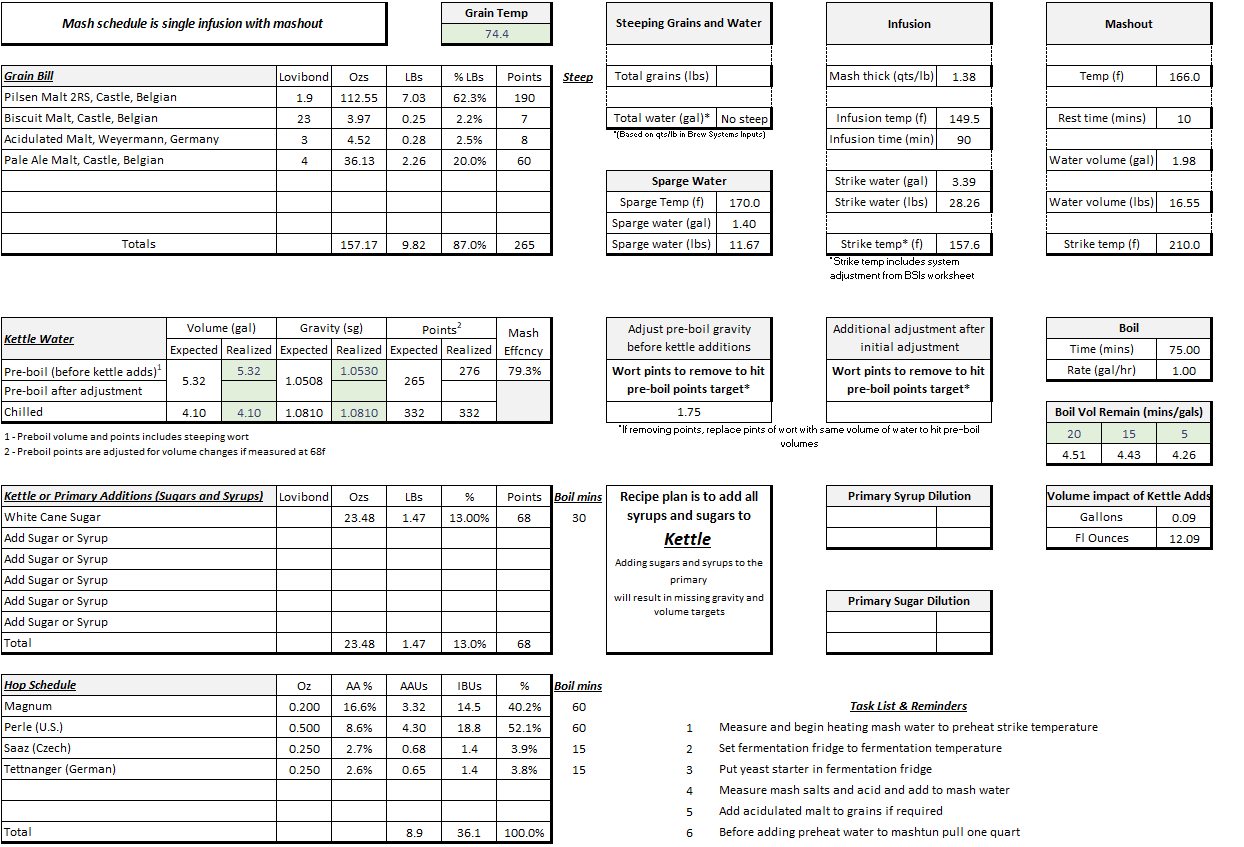

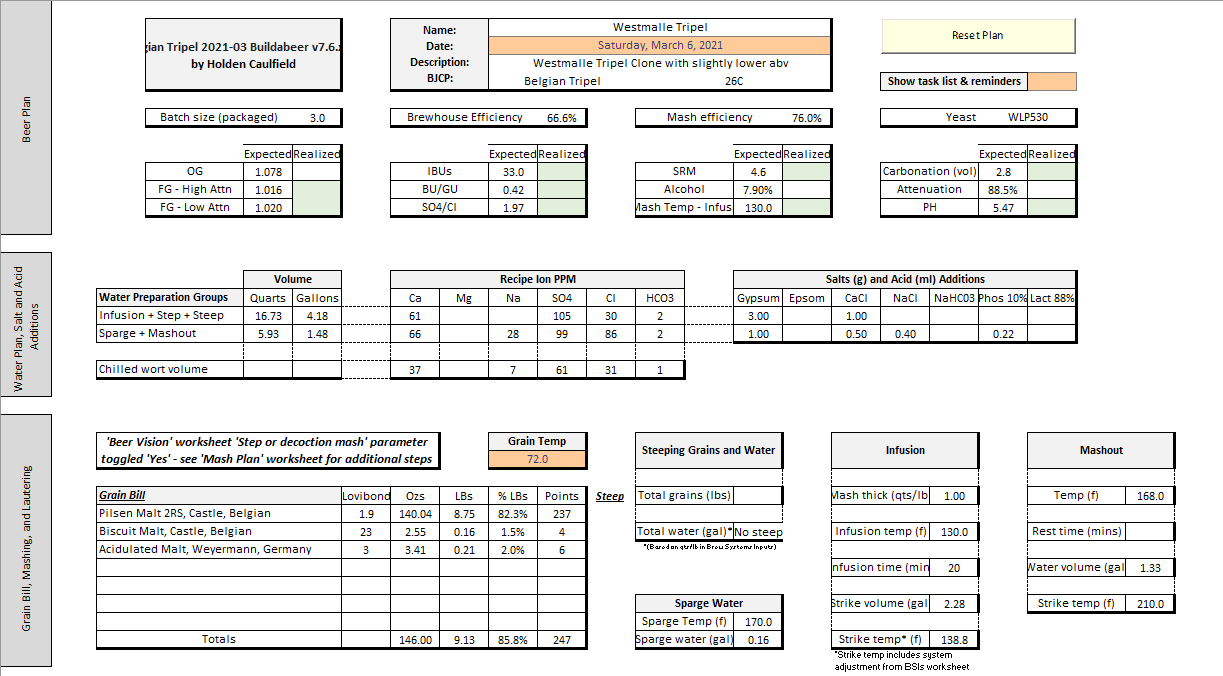

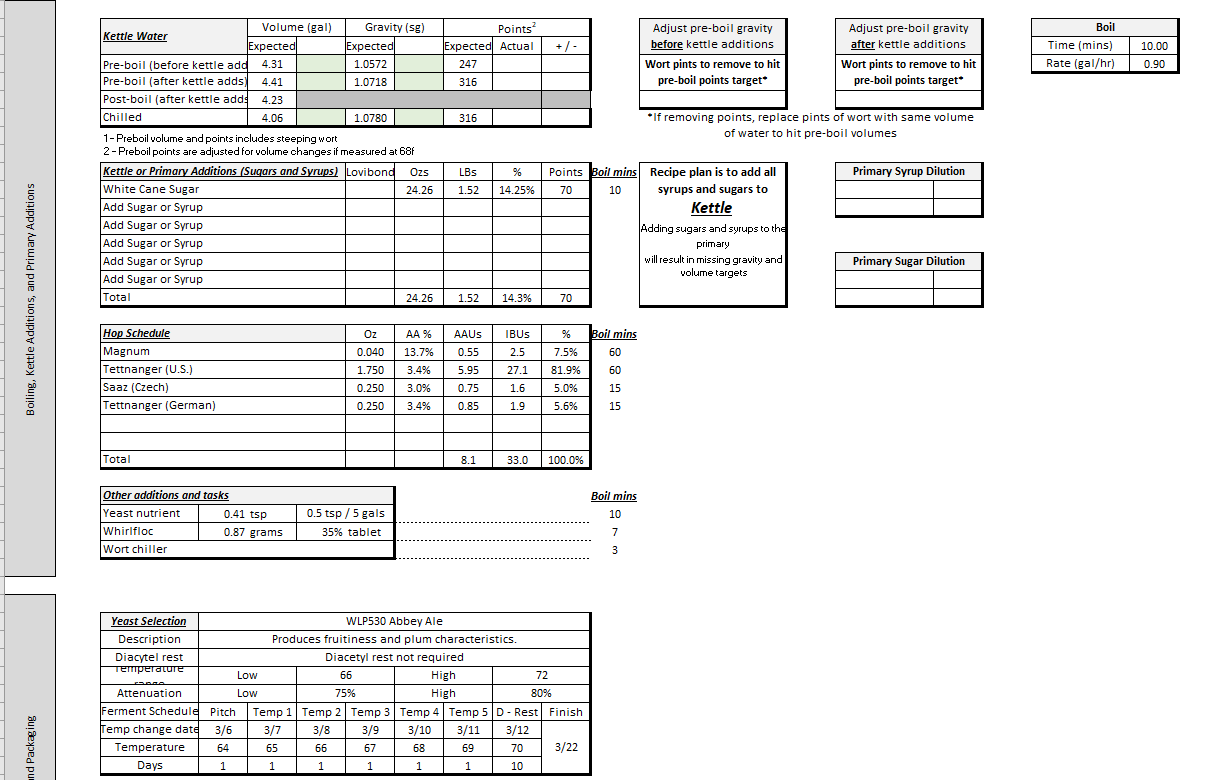

I am brewing a Westmalle Tripel clone-ish beer in the near future and would like to obtain best practice thoughts on a few questions from brewers that have far more experience than me brewing high gravity Belgian beers. The grain bill is quite simple (% are by weight):

84.0% Belgian Pilsner Malt

1.5% Belgian Biscuit Malt

2.0% Acidulated Malt

12.5% White Cane Sugar

Original gravity target - 1.078

The yeast is WLP830 - Westmalle strain

Please let me know your thoughts on the following:

84.0% Belgian Pilsner Malt

1.5% Belgian Biscuit Malt

2.0% Acidulated Malt

12.5% White Cane Sugar

Original gravity target - 1.078

The yeast is WLP830 - Westmalle strain

Please let me know your thoughts on the following:

- Numerous posts and articles suggest that clear candi-syrup or candi-sugar is not necessary and that using ordinary table sugar (aka sucrose) will provide exactly the same level of attenuation and flavor. This is not true of the darker syrups and sugars

- Adding the sugars to the primary after 2-3 days instead of to the boil kettle will help with attenuation as the yeast will not get lazy consuming the simple sugars first

- I will be fermenting 3.4 gallons of wort in a 7 gallon SS Brewbucket so there may be very little Krausen that reaches the top and be blown-off (although the reputation of this yeast is that it is a beast). This means a majority of the giant Krausen will fall back into the finished beer. Will this impact the flavor of the beer? Should a portion of it be skimmed at high Krausen and if so, how much?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)