Lol, Bob!

Actually, by the time you wrote that, I already had the door wet sanded and was running to the stores to get new stuff. When I pulled it out after work, it was a no-brainer that I would be re-doing the blue. There were some thin spots and some drips (in those tight areas of the paint booth).

SO:...

Fridge door with the aqua wet sanded and ready to try again:

Re-masked the door and main fridge using automotive masking tape this time. I also covered the entire fridge this time, as drift from the aqua lingered in the air and landed on the uncovered part of the fridge last time (and since I have no intention or need to repaint the appliance epoxy off-white portion, I'm covering everything:

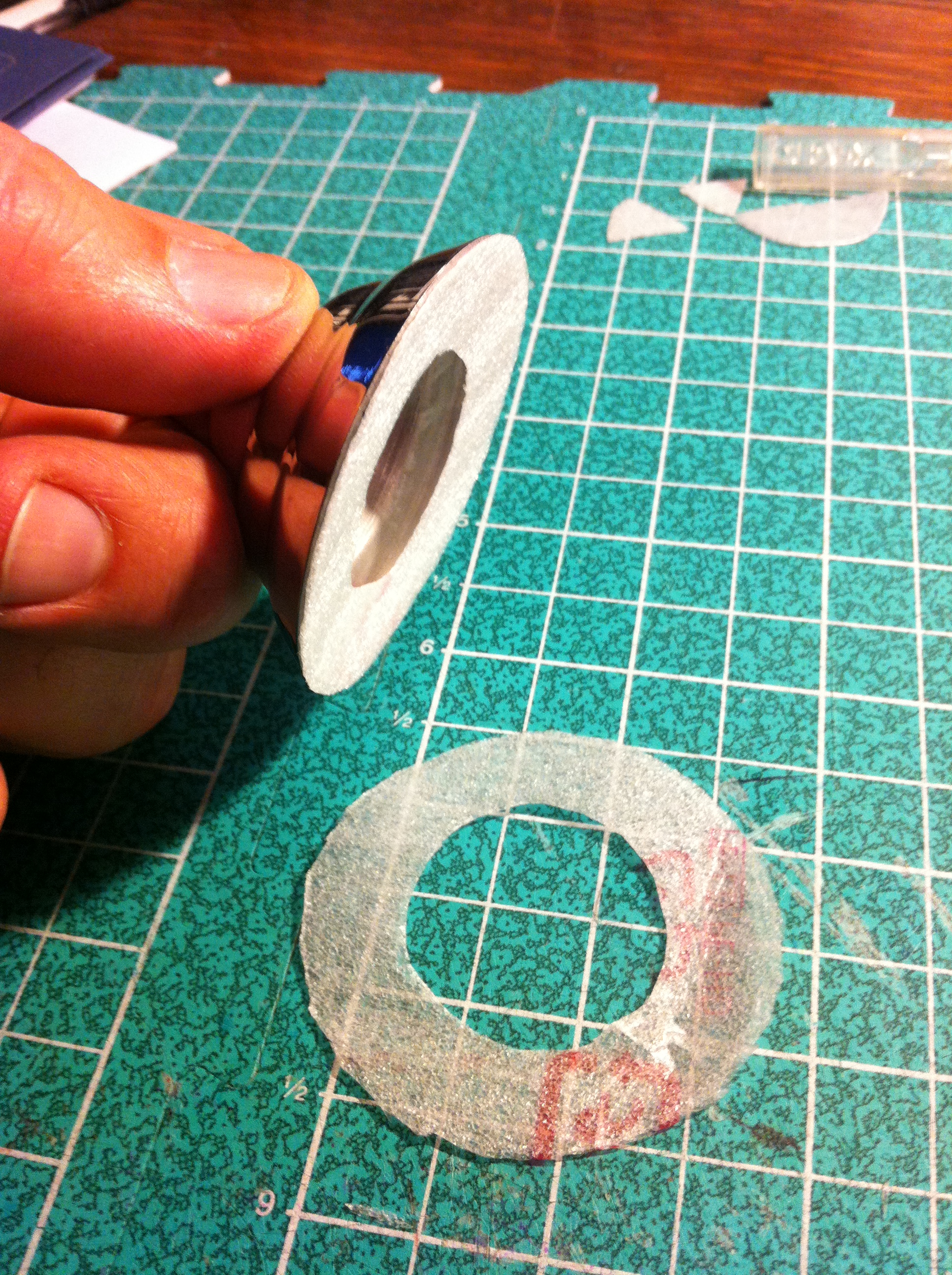

But look what else arrived while I was at the store getting automotive tape, new aqua paint, and clear coat:

With everything ready, I'll paint tomorrow after work!

Actually, by the time you wrote that, I already had the door wet sanded and was running to the stores to get new stuff. When I pulled it out after work, it was a no-brainer that I would be re-doing the blue. There were some thin spots and some drips (in those tight areas of the paint booth).

SO:...

Fridge door with the aqua wet sanded and ready to try again:

Re-masked the door and main fridge using automotive masking tape this time. I also covered the entire fridge this time, as drift from the aqua lingered in the air and landed on the uncovered part of the fridge last time (and since I have no intention or need to repaint the appliance epoxy off-white portion, I'm covering everything:

But look what else arrived while I was at the store getting automotive tape, new aqua paint, and clear coat:

With everything ready, I'll paint tomorrow after work!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)