carpenike

Well-Known Member

"dry fitting" using wood and cinder blocks. Trying to get a rough idea on heights, etc.

Planning on a cart similar to JohnW's (https://www.homebrewtalk.com/f253/single-tier-3-pump-bcs-462-automated-rig-204705/) and the Coloradoan one (https://www.homebrewtalk.com/f253/coloradoan-single-tier-build-345773/). Only I'll just be using 2 pumps to start with and no built in plumbing... having the cart put together in stainless so will likely have the mounts for a third pump put in place just in case and only use two to start with.

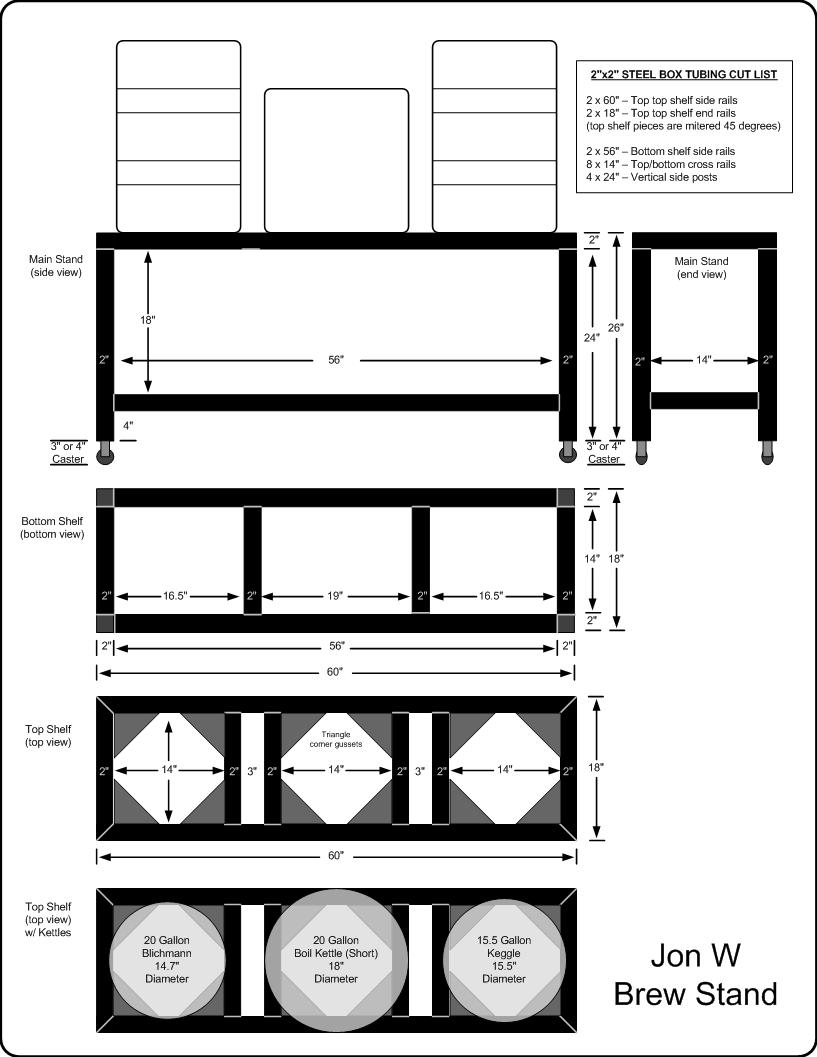

I'll be using JohnW's cart dimensions for the most part:

But I believe I'll have the front top cross beam lower than the rear one and some type of either angled reduction on the arms coming from the back to meet the front bar or just a straight L. This will allow for the bottom drain to be brought to the front without hitting the front cross beam. IE: here's what I'm running into with the wood setup:

Planning on a cart similar to JohnW's (https://www.homebrewtalk.com/f253/single-tier-3-pump-bcs-462-automated-rig-204705/) and the Coloradoan one (https://www.homebrewtalk.com/f253/coloradoan-single-tier-build-345773/). Only I'll just be using 2 pumps to start with and no built in plumbing... having the cart put together in stainless so will likely have the mounts for a third pump put in place just in case and only use two to start with.

I'll be using JohnW's cart dimensions for the most part:

But I believe I'll have the front top cross beam lower than the rear one and some type of either angled reduction on the arms coming from the back to meet the front bar or just a straight L. This will allow for the bottom drain to be brought to the front without hitting the front cross beam. IE: here's what I'm running into with the wood setup:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)