Hey everyone,

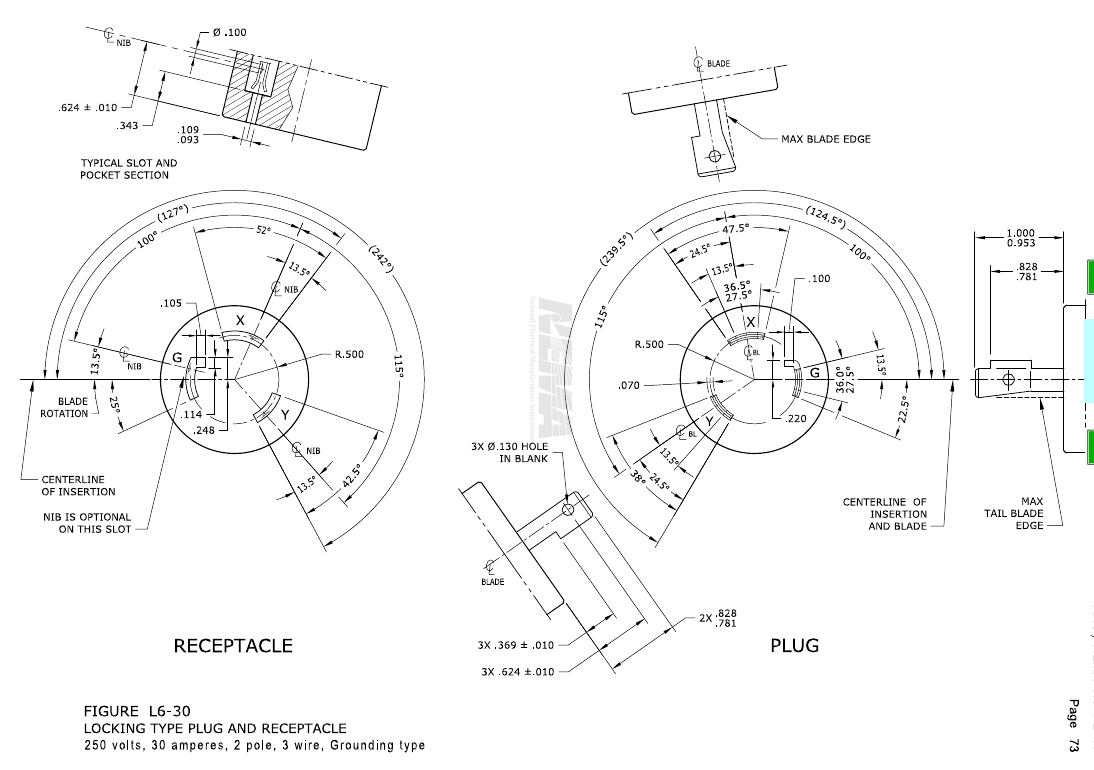

A couple years ago I bought a 220v system that has a 220v element. On the plug it has 3 blades and the plug type is L6-30. It states the unit is rated for 30A.

I purchased their standard ETC controller which is rated for 220v.

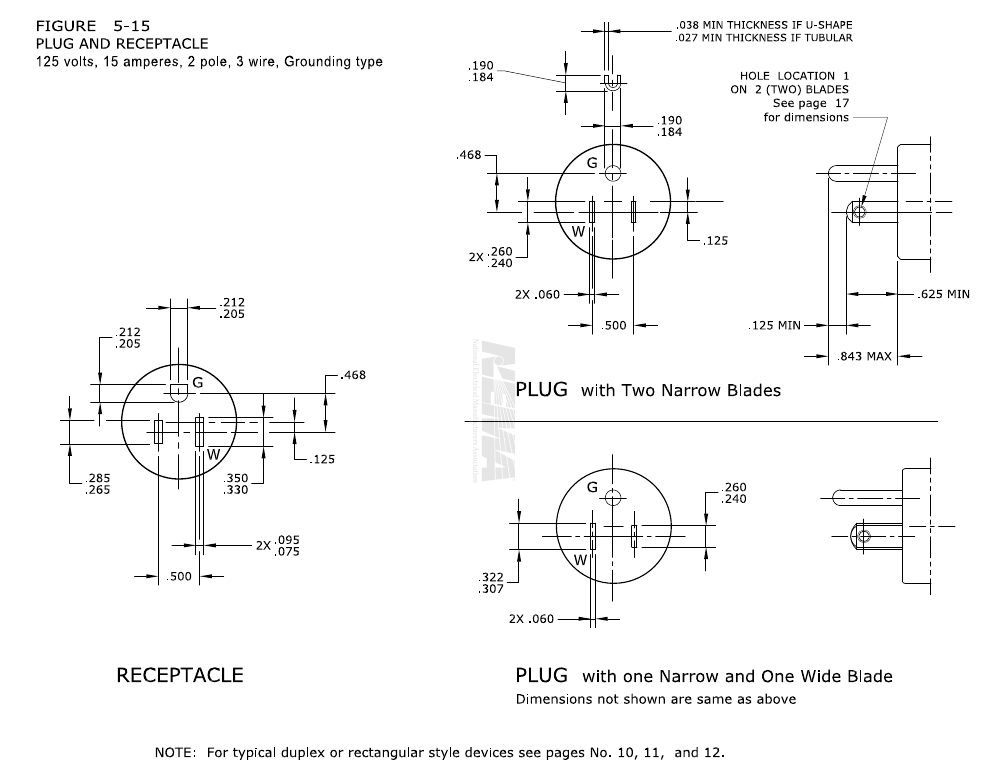

The issue I'm running into is I lost the power cord that goes from the element to the controller. I went into an electrical store, and they said that the two plugs are incompatible and essentially don't want to sell me the setup. They said the LR6-30 is rated for too high an amperage and voltage than the standard 3 blade plug that's on the back of the controller. And that if they are truly pushing the electric that they say, either it shouldn't work (meaning the outlet is only pushing 120 and then wont power the element [or will power it at that reduced rate]), or the 3 blade plug should melt (because its not rated for 220v and 30 Amps.

I reached out to Brau Supply to see how this works. I know they sell a replacement cord on their site and I had it working.

Element Power Cord - - Bräu Supply (brausupply.com)

I guess I am a little concerned about am I going to do something. This is the second electrical professional that has commented at how this plug setup is inappropriate. The first one at the time I didn’t understand what they were saying but in hindsight I put two and two together.

Any advice? Im waiting to see what Brau Supply says just hoping to get some sanity checks.

Also, I am correct in assuming I should have the controller plugged into a GFCI plug right?

A couple years ago I bought a 220v system that has a 220v element. On the plug it has 3 blades and the plug type is L6-30. It states the unit is rated for 30A.

I purchased their standard ETC controller which is rated for 220v.

The issue I'm running into is I lost the power cord that goes from the element to the controller. I went into an electrical store, and they said that the two plugs are incompatible and essentially don't want to sell me the setup. They said the LR6-30 is rated for too high an amperage and voltage than the standard 3 blade plug that's on the back of the controller. And that if they are truly pushing the electric that they say, either it shouldn't work (meaning the outlet is only pushing 120 and then wont power the element [or will power it at that reduced rate]), or the 3 blade plug should melt (because its not rated for 220v and 30 Amps.

I reached out to Brau Supply to see how this works. I know they sell a replacement cord on their site and I had it working.

Element Power Cord - - Bräu Supply (brausupply.com)

I guess I am a little concerned about am I going to do something. This is the second electrical professional that has commented at how this plug setup is inappropriate. The first one at the time I didn’t understand what they were saying but in hindsight I put two and two together.

Any advice? Im waiting to see what Brau Supply says just hoping to get some sanity checks.

Also, I am correct in assuming I should have the controller plugged into a GFCI plug right?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)