It died altogether. I plugged it in this morning just to make sure and it's dead. Had to deuce over to my regular pump during cool down was not easy either. I had no shutoff between the pump and my kettle so I had very poor flow through the little pump. I am gonna email Tim and see what my options would be. I really wish the pump that was supposed to come with the unit is available.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unboxing the Nano from CO Brewing

- Thread starter pretzelb

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Feb 29, 2016

- Messages

- 502

- Reaction score

- 316

Man that sucks. I guess being an early adaptor paid off for me. Tim will make it right though he is good people.

I think I am going to pull the trigger today... 20 gal size, 240V, with the whirlpool port.

I see now they have a touchscreen option for an extra $400. Now I like gadgets, but that would have to be pretty amazing to feel like it was worth the dough. I don't see any details about it on the site.

Those of you who have ordered, any tips? Tweaks you wish you asked for?

I see now they have a touchscreen option for an extra $400. Now I like gadgets, but that would have to be pretty amazing to feel like it was worth the dough. I don't see any details about it on the site.

Those of you who have ordered, any tips? Tweaks you wish you asked for?

jabba11

www.CeeGeeBrewing.com

I think I am going to pull the trigger today... 20 gal size, 240V, with the whirlpool port.

I see now they have a touchscreen option for an extra $400. Now I like gadgets, but that would have to be pretty amazing to feel like it was worth the dough. I don't see any details about it on the site.

Those of you who have ordered, any tips? Tweaks you wish you asked for?

As cool as the touch screen is..no thanks imho. give me a good ole fashioned switch to keep it simple. That said thank god for a PID. I been pretty happy with mine so far. I think I would like for them to include a better way to attach the recirc arm to the kettle to whirlpool but that's not something they are gonna one off for you. You can get an additional port with a recirc fitting though. I wish there were a few add ons like I personally would like something that attahces to the other upright on mine that would hold my phone or a ipad etc that AND a hook for the lid which I never know what to do with and pretty much never use.

Here's a video of the touchscreen.

http://www.cobrewingsystems.com/pages/video

I had assumed it was just a touchscreen version of the PID controller, but it lets you put in mash step temps and times, and it will handle adjusting the temperature for each automatically. You can also add hop steps and get a buzzer to remind you about the next addition.

While you certainly don't need the touchscreen, being able to do multiple mash steps automagically would be a nice convenience.

It's still pretty darn expensive.

edit: aaaaand, I just ordered the 20 gallon version, with the touchscreen. Sucker for gadgets, I am.

http://www.cobrewingsystems.com/pages/video

I had assumed it was just a touchscreen version of the PID controller, but it lets you put in mash step temps and times, and it will handle adjusting the temperature for each automatically. You can also add hop steps and get a buzzer to remind you about the next addition.

While you certainly don't need the touchscreen, being able to do multiple mash steps automagically would be a nice convenience.

It's still pretty darn expensive.

edit: aaaaand, I just ordered the 20 gallon version, with the touchscreen. Sucker for gadgets, I am.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

jabba11

www.CeeGeeBrewing.com

Here's a video of the touchscreen.

http://www.cobrewingsystems.com/pages/video

I had assumed it was just a touchscreen version of the PID controller, but it lets you put in mash step temps and times, and it will handle adjusting the temperature for each automatically. You can also add hop steps and get a buzzer to remind you about the next addition.

While you certainly don't need the touchscreen, being able to do multiple mash steps automagically would be a nice convenience.

It's still pretty darn expensive.

edit: aaaaand, I just ordered the 20 gallon version, with the touchscreen. Sucker for gadgets, I am.

Its a pretty cool gadget I admit. If I was doing a commercial setup it would be a must have I will admit that

The touchscreen controller also has support for automating water additions. The Nano Home doesn't have the hardware like their bigger systems, but Tim said that you can add on a 24V solenoid and a water meter with pulse output. Totally unnecessary... but totally cool.

02RedWS6TA

Well-Known Member

I'll be installing automated water. Got a set up off Ebay for $45 shipped, we'll see how well it works. The touchscreen wasn't an option when I ordered, if it was I'd have definitely went for it.

jabba11

www.CeeGeeBrewing.com

Mashed in the first wheat beer I've done in mine. Definitely a different experience. I did the sac rest and added 6 oz of rice hulls and while it is recirculating its doing it very slowly compared to the ales I have been doing. Really gotta pay attention to it and I did quite a bit of stirring at first . I'm trying to let it do its thing now and checking it every 3 or 4 mins. I am noticing that it does have a harder time holding temp with the recirc running slower with "wilder" swings but nothing too bad. its seems like its really just a matter of letting it find its equilibrium so to speak for each batch them it will just run.

I've got the Beersmith equipment profile for the Nano 20 gal, but how are you guys setting up the mash process?

jabba11

www.CeeGeeBrewing.com

I've got the Beersmith equipment profile for the Nano 20 gal, but how are you guys setting up the mash process?

Id need a little more info about what you are asking. My Mash temps are based on recipe. how much water is based on grain and desired gallons of beer your brewing all of which are calculated. If I am doing a sac rest I have to add that in (for wheat beers). For mashing I heat the water to a few degrees above my desired mash temp. Once it reaches that temp I dump all the grain into the basket and set it for my desired mash temp. I stir it a few times while it finishes heating to my desired mash temp and then I simply let it recirc on its own. Once I am done mashing I turn it up to sparge temp usually with a 5-7 min rise time and then 10 mins at sparge temp 168-170. Helpful?

The recipe is the easy part -- like, mash at 150F for 60 minutes, or add a ferulic acid rest, etc. It's how to tell Beersmith what I want that I am trying to figure out. Beersmith needs to know how much water to use and what the mash steps are to calculate gravity and pH, right?

I've been doing AG in coolers for a while, and in the mash setup you tell Beersmith how much water per pound of grain you want to use, and the temperature of the grain, and it figures out a strike temperature and tells you how much water you need. But with this electric recirculating system I know we have to use more water per pound of grain, and I am sure there are other changes too, and I am not sure how to configure Beersmith for that.

Beersmith has a big list of mash profiles and I am unsure which one is the closest starting point for the Nano Home.

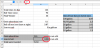

And if you look at the details inside a mash step, I'm not sure how to set this stuff up either.

I've been doing AG in coolers for a while, and in the mash setup you tell Beersmith how much water per pound of grain you want to use, and the temperature of the grain, and it figures out a strike temperature and tells you how much water you need. But with this electric recirculating system I know we have to use more water per pound of grain, and I am sure there are other changes too, and I am not sure how to configure Beersmith for that.

Beersmith has a big list of mash profiles and I am unsure which one is the closest starting point for the Nano Home.

And if you look at the details inside a mash step, I'm not sure how to set this stuff up either.

OK, answering my own questions here! I think I have figured this out and would appreciate your input.

First, the CBS water calculator seems to have an error. The Loss to Boil field C12 is fixed at 3.

I believe that this value should be calculated from your boil off rate (per hour) and the length of the boil. C12 should probably be this equation: =C3/60*C7

The CBS water calculator has a field for Grain Absorption Rate, C7. The default value is 0.1, which I believe must be in gallons per pound. You can make Beersmith's match this value if you look in the Advanced settings under BIAB Grain Absorb. Beersmith's default value here is 0.586 fl oz/oz. You can make this value match the CBS spreadsheet value of 0.1 gal/lb if you enter 0.8 fl oz/oz.

In Beersmith, the BIAB mash profiles will use all the brewing water at once, so I guess that's the base mash profile to start with. Copy one of the existing BIAB profiles to a new Nano Home version and adjust the step temperature as needed.

Now, build a Beersmith recipe with the CBS equipment profile and the BIAB-based mash profile. Then put the total grain bill, boil time, and final volume into the CBS spreadsheet. You should see pretty good agreement between the CBS spreadsheet total water amount and the Beersmith total water amount.

(Your actual boil-off rate may be different than the values in the CBS spreadsheet depending on altitude etc, but enter your true value both in the Beersmith equipment profile and the spreadsheet and everything should work out.)

My test recipe with 10.97 lb grain and a 5.5 gal final batch size came out to 8.66 gal in the CBS spreadsheet, and 8.64 gal in Beersmith. Now, I feel like I can design a recipe in Beersmith and get water volumes that match the CBS worksheet.

Then again, I don't have my Nano Home yet so maybe all of this will fall apart!

Later I will post a modified version of the CBS spreadsheet with the correction I mentioned, plus some edits for clarity. Looks like I can't attach ODS or Zip files here.

First, the CBS water calculator seems to have an error. The Loss to Boil field C12 is fixed at 3.

I believe that this value should be calculated from your boil off rate (per hour) and the length of the boil. C12 should probably be this equation: =C3/60*C7

The CBS water calculator has a field for Grain Absorption Rate, C7. The default value is 0.1, which I believe must be in gallons per pound. You can make Beersmith's match this value if you look in the Advanced settings under BIAB Grain Absorb. Beersmith's default value here is 0.586 fl oz/oz. You can make this value match the CBS spreadsheet value of 0.1 gal/lb if you enter 0.8 fl oz/oz.

In Beersmith, the BIAB mash profiles will use all the brewing water at once, so I guess that's the base mash profile to start with. Copy one of the existing BIAB profiles to a new Nano Home version and adjust the step temperature as needed.

Now, build a Beersmith recipe with the CBS equipment profile and the BIAB-based mash profile. Then put the total grain bill, boil time, and final volume into the CBS spreadsheet. You should see pretty good agreement between the CBS spreadsheet total water amount and the Beersmith total water amount.

(Your actual boil-off rate may be different than the values in the CBS spreadsheet depending on altitude etc, but enter your true value both in the Beersmith equipment profile and the spreadsheet and everything should work out.)

My test recipe with 10.97 lb grain and a 5.5 gal final batch size came out to 8.66 gal in the CBS spreadsheet, and 8.64 gal in Beersmith. Now, I feel like I can design a recipe in Beersmith and get water volumes that match the CBS worksheet.

Then again, I don't have my Nano Home yet so maybe all of this will fall apart!

Later I will post a modified version of the CBS spreadsheet with the correction I mentioned, plus some edits for clarity. Looks like I can't attach ODS or Zip files here.

jabba11

www.CeeGeeBrewing.com

Ok. I see what your asking kind of. For me, yes, I use BIAB light body for say my light ales. Now that said I adjust mash temps etc for the recipe under mash. Water is calculated based on grain bill and desired gallons of cooled wort and is calculated by beersmith for you. I have found it to be reasonably accurate. (within a half gallon or so) Boil off rate is the real variable here. I admit that beersmith isn't the most user friendly thing ever and Ive been using it so long I can forget what its like to look at what appears to be daunting. For my water chemistry I use bruinwater and don't fiddle much with beersmith although the new version has a few more features in that regard I haven't played with yet.

Thanks. I just pinged Tim at CBS and he also verified the Beersmith BIAB mash profile will work, and you can just use that instead of their spreadsheet. Beersmith and CBS are using different values for grain absorption but the end results are pretty close. I guess we should all calculate our own absorption value, which will be dependent on crush and grain type anyway.

30Bones

Well-Known Member

I need to get my laptop running so I can use the full BS potential. The app is limited.

Getting really close to brewing and have yet to mess with calibration or setup parameters

Getting really close to brewing and have yet to mess with calibration or setup parameters

jabba11

www.CeeGeeBrewing.com

I need to get my laptop running so I can use the full BS potential. The app is limited.

Getting really close to brewing and have yet to mess with calibration or setup parameters

Yes, I do all my calcs on the puter typically then save to the cloud and copy back to my phone just before brewing. I have actually built most of recipe in my phone before but theres some things you cant access etc.

30Bones

Well-Known Member

OH I build recipes all the time with the app, but equipment profiles are so much more powerful on a PC. Not to mention the add ons for hops, grains, yeasts, etc.Yes, I do all my calcs on the puter typically then save to the cloud and copy back to my phone just before brewing. I have actually built most of recipe in my phone before but theres some things you cant access etc.

02RedWS6TA

Well-Known Member

Brew day number 3 today. Water automation was hooked up last night, definitely the way to go. Cherry wheat today, using a hop spider today for the first time, brewing starts at 5.

Your rig is pre-touchscreen right? So your water automation is DIY, not CBS-style?

What kind of hop spider did you get? I need to get something like that, but my situation is complicated by the fact that I am getting a 20 gallon system and usually using it for 5 gallon batches. If I had a hop spider on top of the kettle, it'd be a pretty huge bag!

What kind of hop spider did you get? I need to get something like that, but my situation is complicated by the fact that I am getting a 20 gallon system and usually using it for 5 gallon batches. If I had a hop spider on top of the kettle, it'd be a pretty huge bag!

I didn't have a hop spider and used some whole hops which quickly clogged the pump. I was thinking of getting one but didn't know if it would be able to reach the wort effectively since it was such a small amount in a larger kettle. So I rigged up a bazooka screen with the pickup tube at an angle. I haven't tried it out but will see if it will fix the hop debris issue next time. View attachment ImageUploadedByHome Brew1472155501.054757.jpg

02RedWS6TA

Well-Known Member

Your rig is pre-touchscreen right? So your water automation is DIY, not CBS-style?

What kind of hop spider did you get? I need to get something like that, but my situation is complicated by the fact that I am getting a 20 gallon system and usually using it for 5 gallon batches. If I had a hop spider on top of the kettle, it'd be a pretty huge bag!

It is pre touch screen. The automation worked awesome, $45 well spent. Just ebay search 1/2" automated flow meter. It was calibrated perfect from the factory. Ended up with two 6.5 gallon batches which is what I was aiming for.

As far as the hop spider I got mine from Arbor fabricating but they can be had other places cheaper. I believe arbors are made on site. It worked great for the 60 and 0 minute hops, the 10 minute hops I just dumped in to the boil due to too much drinking during brewing. Between the two of us we finished 18 beers

.

. Wort is in the carboy with a large yeast starter, only 20 hours on the starter so hopefully it still takes off. Full video of the brew was taken so I will update once edited.

30Bones

Well-Known Member

I was thinking something like that would be in order with that huge pick up tube. For the time being I plan to just use hop bags, but when I get to a hoppy IPA I may want to have this mod in place.I didn't have a hop spider and used some whole hops which quickly clogged the pump. I was thinking of getting one but didn't know if it would be able to reach the wort effectively since it was such a small amount in a larger kettle. So I rigged up a bazooka screen with the pickup tube at an angle. I haven't tried it out but will see if it will fix the hop debris issue next time. View attachment 367740

Received my 20 gallon down under system this week and got it dry fitted. Cleaned everything but haven't had a chance to run water through it yet. I do have one question for folks that are still doing 5 gallon batches. The kettle that came with mine is actually 100 quarts (25 gallons) and I'm worried that it is going to be too big for running 5 gallon batches. I looked up the specs on concord's site as they are the makers of the kettle and it looks like the 100qt is 2 inches wider than the 80qt. Any thoughts would be greatly appreciated as I try to decide if I should contact Tim to ask for the smaller kettle.

Huh. Before I ordered my Nano Home 20 Tim verified it would do 5 gal batches. Your kettle definitely looks bigger than what I remember seeing though, and I thought our setups were more alike than different. (Mine hasn't shipped yet.)

You also have the bigger touchscreen which I did not think was needed on one vessel systems.

When did you order?

You also have the bigger touchscreen which I did not think was needed on one vessel systems.

When did you order?

I ordered back in May, but delayed the delivery because I wanted the touchscreen. The touchscreen is actually the smaller 4.3 inch for the single system, they originally were going with 3.5 but decided the extra space was better. I too had verified with Tim before ordering back in May about the batch sizes. When I first put everything together I thought I had a smaller mash basket because I had so much extra space inside the kettle, then I saw the size markings on the kettle and it was the larger 100qt size, extra 2 inch diameter makes a big difference.

Looking through all the pages on the thread and it looks like people with 20 gallon systems have the correctly sized 80qt kettles.

Looking through all the pages on the thread and it looks like people with 20 gallon systems have the correctly sized 80qt kettles.

Weird, I hope it works out.

How are you managing waste chill water in that space? Is there a door to the outside or a drain just out of frame?

How are you managing waste chill water in that space? Is there a door to the outside or a drain just out of frame?

This is down in my basement and about 10ft away is a sink with a pump which I will just run a longer hose to. My washer and drier are right above it so I plan to tap into that waterline for easy kettle filling.

I'm kind of torn because on one hand I can make bigger batches but if it will be too much of a pain to continue doing 5 gallon batches I think I'll want to have it swapped out.

I'm kind of torn because on one hand I can make bigger batches but if it will be too much of a pain to continue doing 5 gallon batches I think I'll want to have it swapped out.

In your situation I'd probably have to swap. I got the 20 gallon system because I want the option to do bigger batches, and I expect to be using this system for many years. But today, I am all about 5 gallon batches.

I should drop Tim a line and make sure I don't end up with the bigger kettle. Can't hurt to bring it up.

I should drop Tim a line and make sure I don't end up with the bigger kettle. Can't hurt to bring it up.

Similar threads

- Replies

- 11

- Views

- 706

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 752

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)