First day brew notes are in!

Overall impression: wow. Easier, more efficient, and faster than I've ever brewed before. I swear I've had tougher times with extract batches! Keep in mind I didn't get the full nano system- just the kettle and recirc fitting.

First note- this was a wit with 50% flaked wheat. The LHBS forgot the rice hulls. I also just milled to their standard setting (did not get exact specs). That said, I had no recirculation issues at all. 3/4 throttle for most of the hour. I also achieved ~70% brewhouse effeciency, which I am very happy with. The grains still definitely had a lot of sweet wort, so I may do a simple pour sparge next time.

Second- The only complaint I have about the whole CBS system was the mounting of the recirc fitting. It's just not a very 'elegant' connection. I eventually found a roll of electrical tape jammed in there did the job. I'll figure something out for the future.

Third: I think I had an above average brew day length before, but today was SIGNIFICANTLY shortened. Times, as per my notes (5 gallon batch):

1:50- Start heating strike

2:25- Mash in (could have been sooner, fiddling with PID and probe)

3:27- Hoist basket

3:35- Start beating for boil

3:47- Boil achieved

4:47- Kill boil and start chill

4:54- 150* 5:08- 80*

5:14- carboy in fridge

6:34- all clean

This timetable is lightning speed compared to what I'm used to. Brewing was absolutely an all day affair. Between shortened setup, breakdown, cleaning, and heating, I shaved an easy 3 hours off. There are probably 30 minutes in there of me fiddling in figuring things out. This speed (and accompanying effiency) is the part I'm happiest about.

All in all couldn't be more pleased. Not only am I done sooner, I used to be absolutely BEAT after brewing. Today was tough work, but nowhere near what I'm used to, and it'll only get easier.

Now for some pics!

Mash (recirc fitting holder V1)

"Sparge"

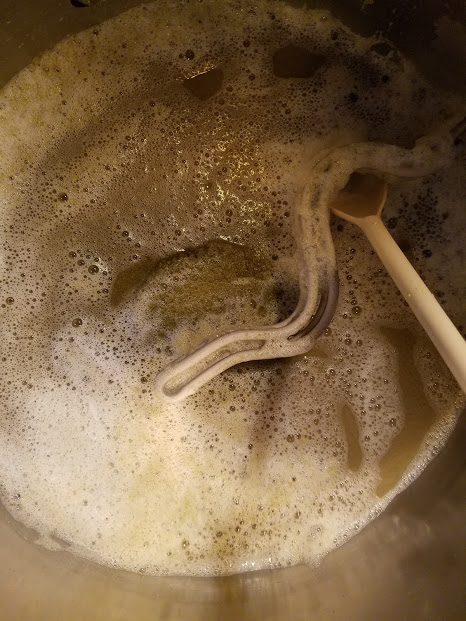

Boil

Chill

(recirc holder V2)

(Bro check my trub cone)

Oh yeah- it's hard to tell from that last pic but the pickup tube gets pretty much everything. I used .75 gal equipment loss and it was spot on, including what was left in the CFC.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)