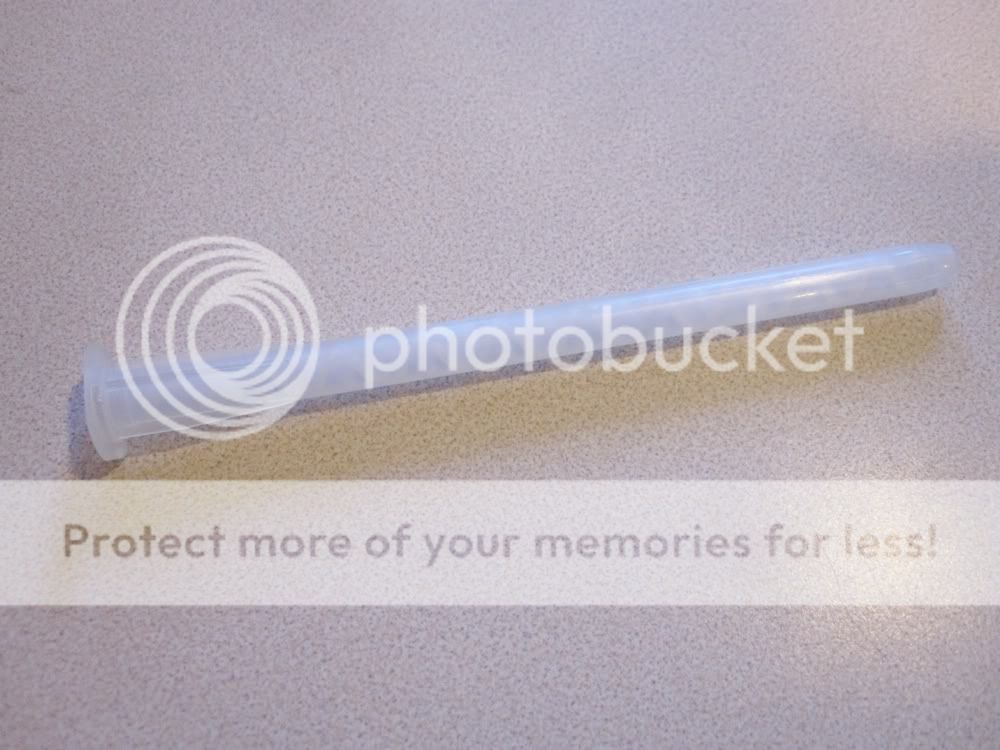

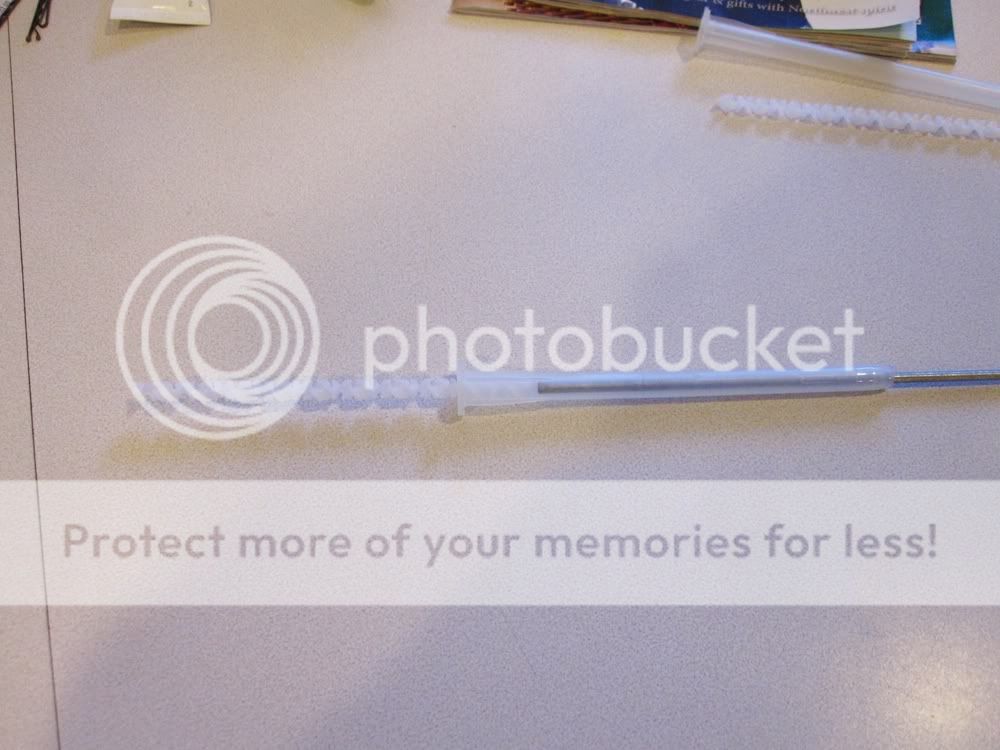

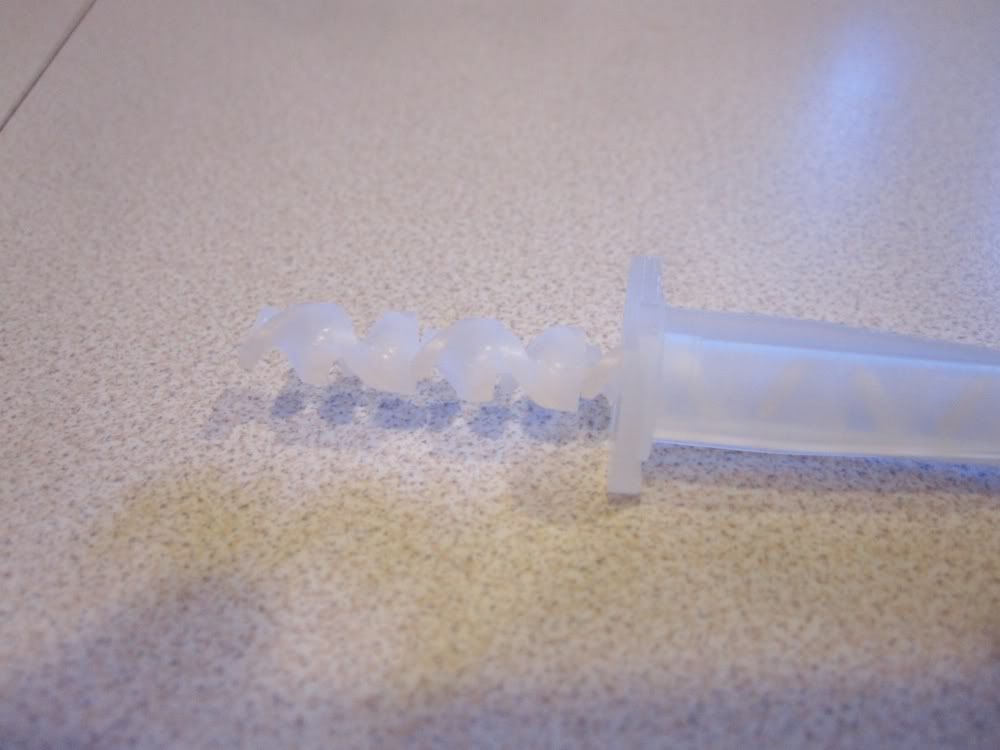

I've been using some of these mixing sticks for a while now. And although they definitley slow down the pour it seems to me that they may be knocking out the gas from the beer as it flows over the mixers. I just find the beer doesn't have much carbonation after I pour. Yes, I don't get a glass of all foam, but now I hardly get a head at all. Does anyone else see this happening?

I've just started using them and haven't tried them with a fully carbed batch other than my Oatmeal stout which tends to have a low fast dissipating head due to the oils. It pours with very little head for me using 2 sticks -- which is probably slightly too much resistance -- but if I half open my picnic tap and give it a shot of foam it gets a decent head on it.

I've got a few batches that should be carbed up properly soon (I'm a set and forgetter) and then I'll report back. I'd expect if the CO2 was getting knocked out though, you'd see foam though since it'd happen on the way through the tube out... much like the restrictor plate in a stout faucet causes the co2 to knock out and foam.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)