Thanks !It's looking awesome!

Probably just straight up as per the drawing. The flue pipe and an elbow come with it in a kit. Both are stainless steel. I might put on a big ole exhaust stack for effect...Where is the water heaters flue going to discharge?

The heater MUST be run on pressurized water. I believe there is a pressure sensor inside it and it will shut down on low pressure. The pressure is needed to keep the water from turning to steam inside the heat exchanger. It exits the hot water heater at 140F with the stock thermostat and 180F (IIRC) with the accessory thermostat, but parts of the heat exchanger might be hotter than that.I'm not sure how you could get low pressure hot through a water heater as that's 1 of the reasons we have them the only way I personally can think of doing it is

Getting the smallest copper cylinder possible and having a small header tank and an immersion heater in the tank and using your heater for your tap....but it wouldn't be worth it for the price of the heater and it wouldn't be portable unless you had the cylinder set up on another frame with casters connected with flexible /push fit john guest fittings, snap on snap off for storage,

Hope you can come up with a way though!

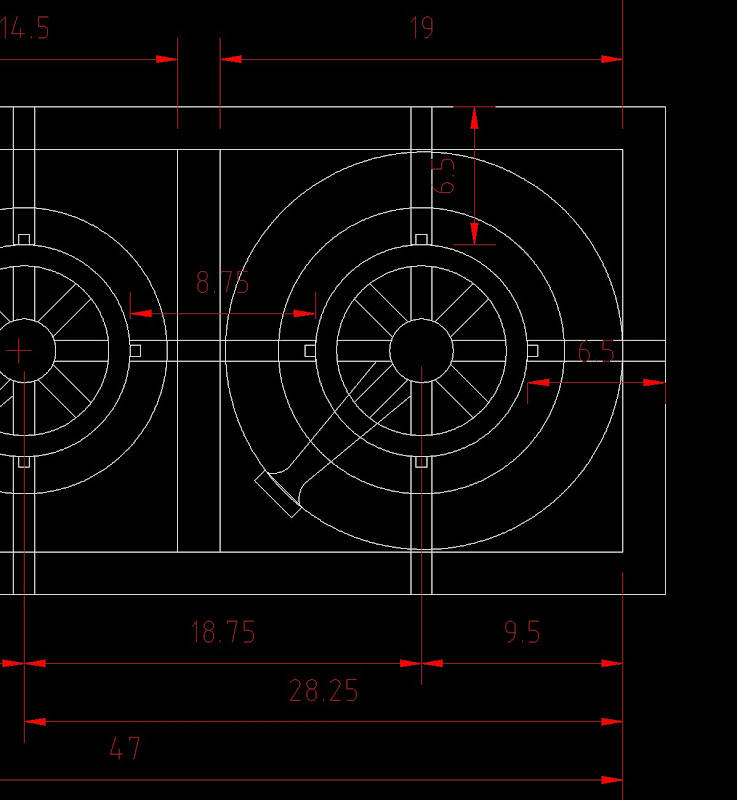

All I need to do is have 2 water pressure regulators, one on the hot water line/valve going into the manifold and the other on the cold water line/valve going into the manifold.

The only thing i don't know about is the temp rating of the regulators. I doubt that its standard practice to have a water pressure regulator on a hot water line.

The other thing i could do is put a safety relief valve set at 5 PSI on the manifold and just allow it to blow off if the pressure is exceeded.

The only thing I need either of these for is because I want hot and cold water valves going directly into the manifold so that vessels can be filled, things can be flushed, etc. Neither the pump head nor the silicone hoses are designed for high pressure, thus the need for something to protect them. As long as one runs the manifold valves properly, neither of these components would see high pressure, but on brew day, when you have a 1000 things on your mind, I can't rely on myself to remember that. Thus the need for protection in the form of a relief valve or upstream pressure regulators.