So I got a bit of time to work on this thing.

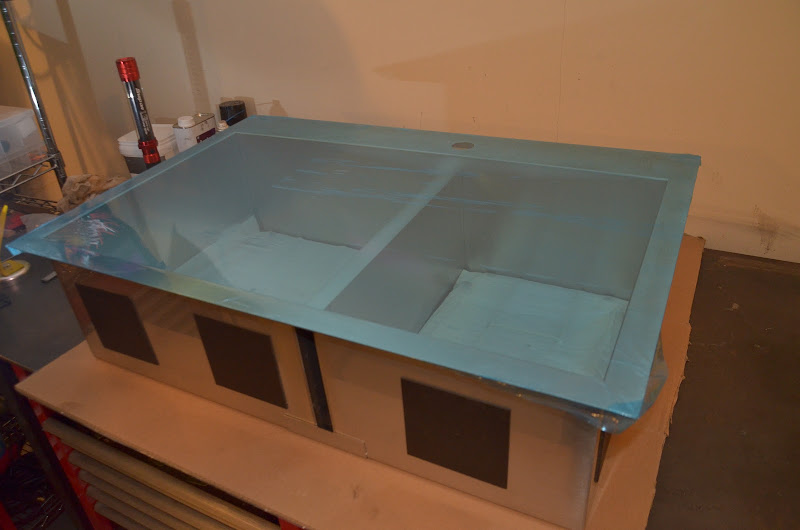

Of the best laid plans of mice and men... In the time I wasn't working on it, I stumbled on a large decently sized sink at our local Costco for $220.

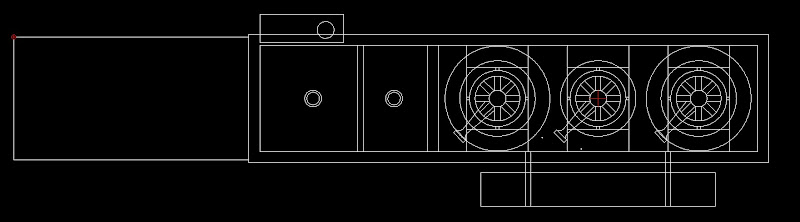

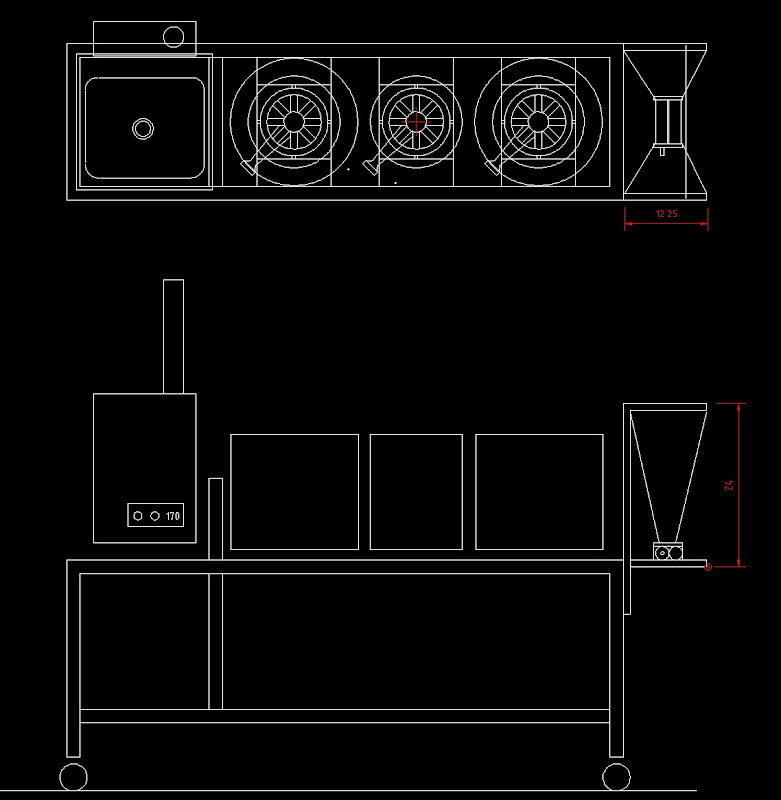

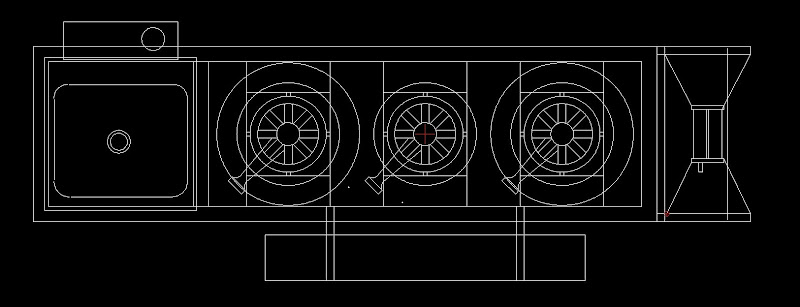

The main sink is 17x17. The side sink is 12x17. 9? inches deep. It comes with racks for the bottom of the tubs and drains.

I've been trying to get one of the medium sized restaurant sinks used, forever, to no avail. If you think $220 is a lot of money for a sink, I dare you to go sink shopping these days.

What I like about this sink is having 2 tubs (one can be for soaking or rinsing) and the tubs are flat right to the edge, so that things don't fall over if placed near the edge. And the tubs, both of them, are big enough to hold big things, like a keg upside down, draining.

Problems.

1) Cost. Luckily, I've been a good boy this year so Santa is getting it for me.

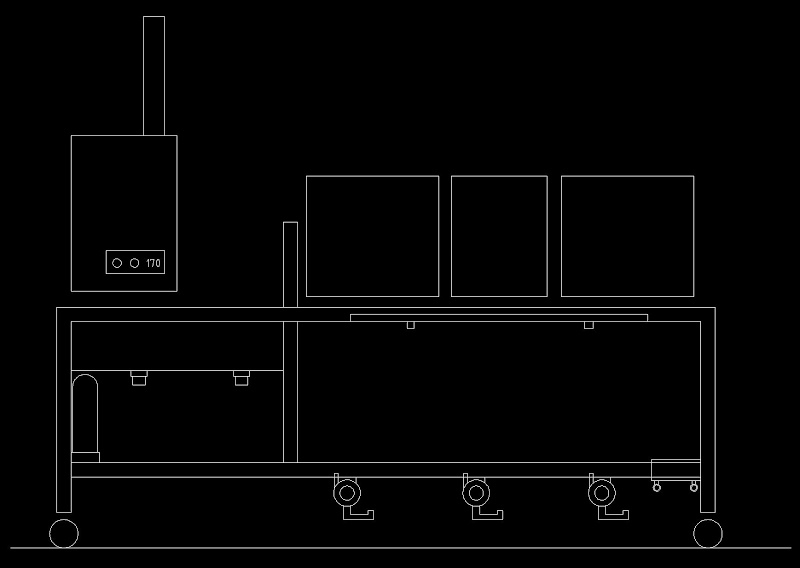

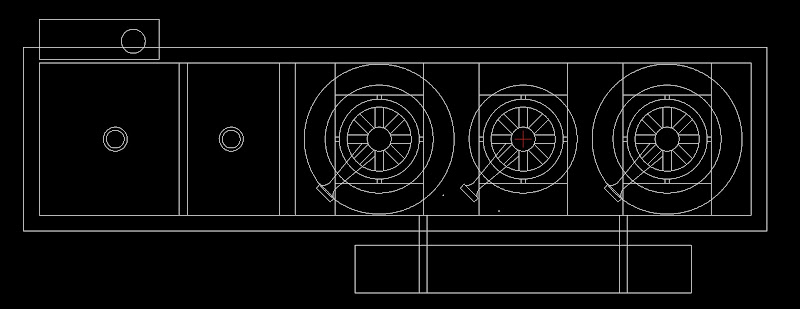

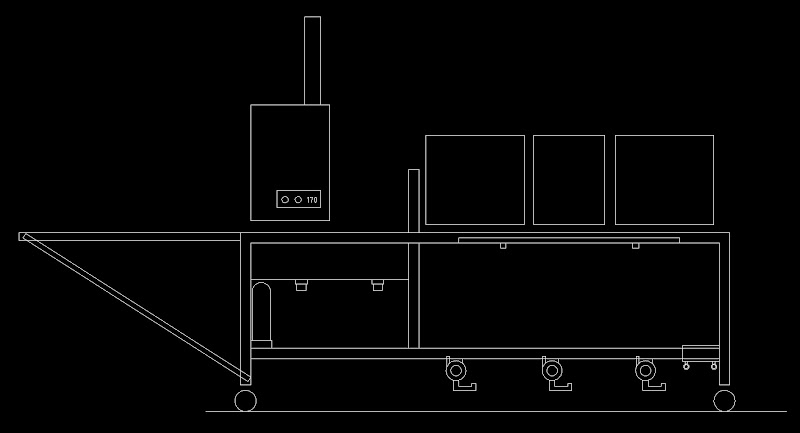

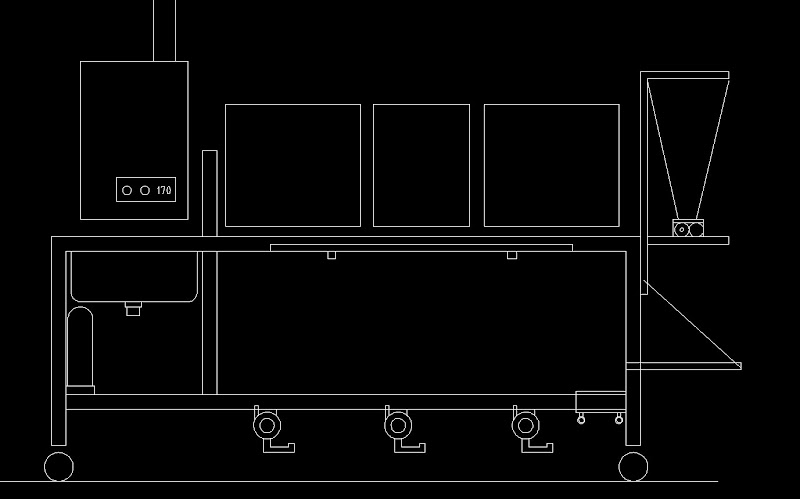

2) The stand becomes longer by about 11 inches, from 82 inches to 93 inches. So it takes up more room. I'm storing it outside, so it isn't that big of an issue, but it is getting large.

On the other hand, because the stand has hot water and burners and a sink and a shelf, its going to be able to do double duty as a food prep center if we host an event outside somewhere or on our deck.

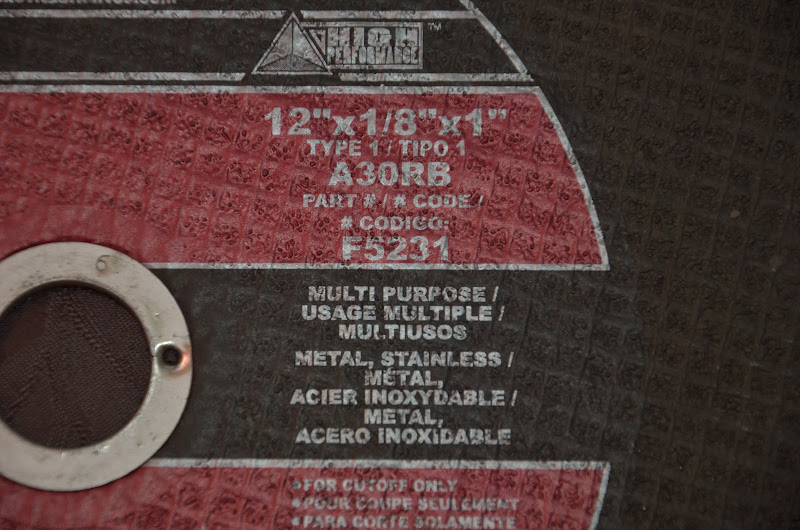

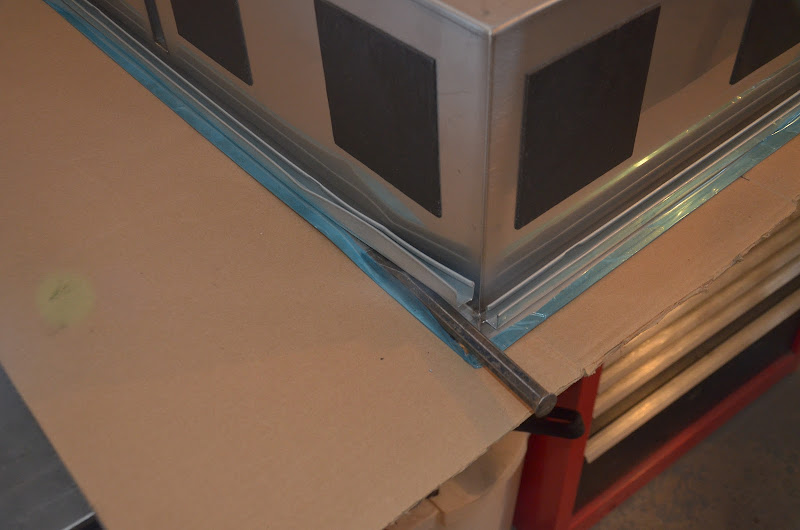

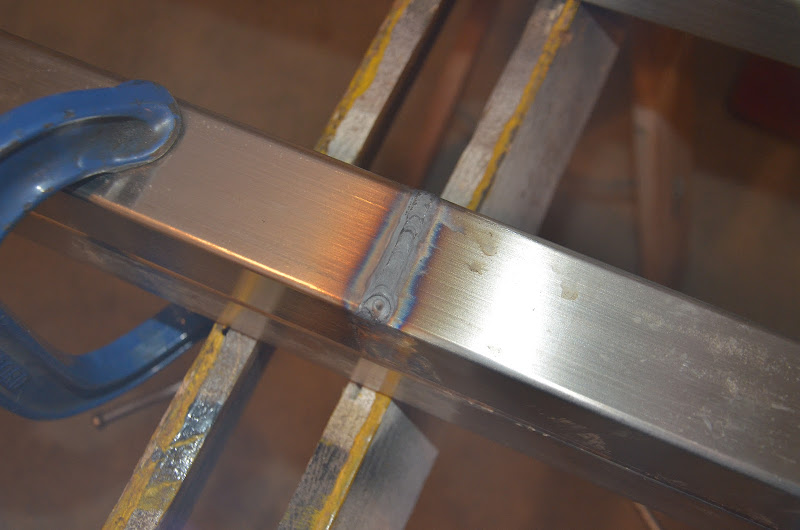

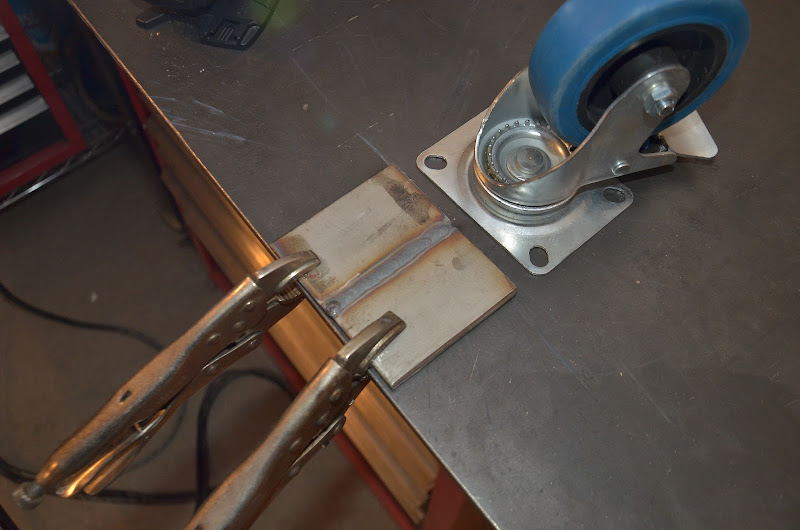

3) I need to lengthen my stand by about 11 inches, from 82 inches to 93 inches. I already cut my long pieces at 82 inches. I now have to weld 11 inches onto each of them. If I grind and polish the welds, you wouldn't be able to tell.

4) The sink has a mounting track under the lip that stands about 1/2" high. Its spot welded about every 3/8" to the lip. This prevents the sink from sitting flat on the SS tubing, which I would like it to do. I have no idea how I would remove it without wrecking the sink.

Ideas ?

I also purchased a different fawcet.

It was $135. I'll return the other one which was $80. I need to put a longer hose on this one so that it will reach right to the bottom of the sink and over into my mash tun to fill it.

I decided to upgrade these components after seeing pictures of Mr. Blichman's setup in the home brewery design article in the November 2012 issue of Brew Your Own. He, of course, uses the real, large, restaurant sink with the real restaurant fawcet. I can't afford those, but I can afford this.

My brewstand is getting expensive. But on the other hand, my wife doesn't want me brewing in the house and even if she did, I don't have a room in it to do so. This is the easiest, cheapest way to build something similar to a custom brewing room in a house without actually doing so. And if I ever do get to have a brewery room in a house, all this stuff will fit right in.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)