In the earlier Wort Hog controllers (maybe currently as well but I don't have one of those to comment on), The PID used a low current internal relay to open and close the control loop of an SSVR (a real SSVR module as witnessed by my own eyes). The potentiometer still controlled the effective power output but the PID decided when to call for heat or not. I'm sure it works fine but whether it's needed in reality is suspect.

Here's a rub though. I have an SSbrewtech 2V controller open on my desk right now and the two relays inside the box are just standard SSRs with 3-32VDC trigger input. It sounds like potential creative marketing in my opinion. If it supposedly functions "LIKE" an SSVR, I'd love to know how they would do that without an actual SSVR. Maybe their PID has remarkably short cycle duration that acts more like an SSVR in that the pulsing is faster/smoother. I looked up the Omron E5CC and it does in fact have an optional 100 milisecond control period. So...

Regarding the post above, I think of SSVR differently than switching on and off. It's more of sine wave sculpture.

I would say it's semantics though. A sine wave itself is already turning on and off 30 times a second. The SSVR just shortens how long it's on for 30hz cycles.

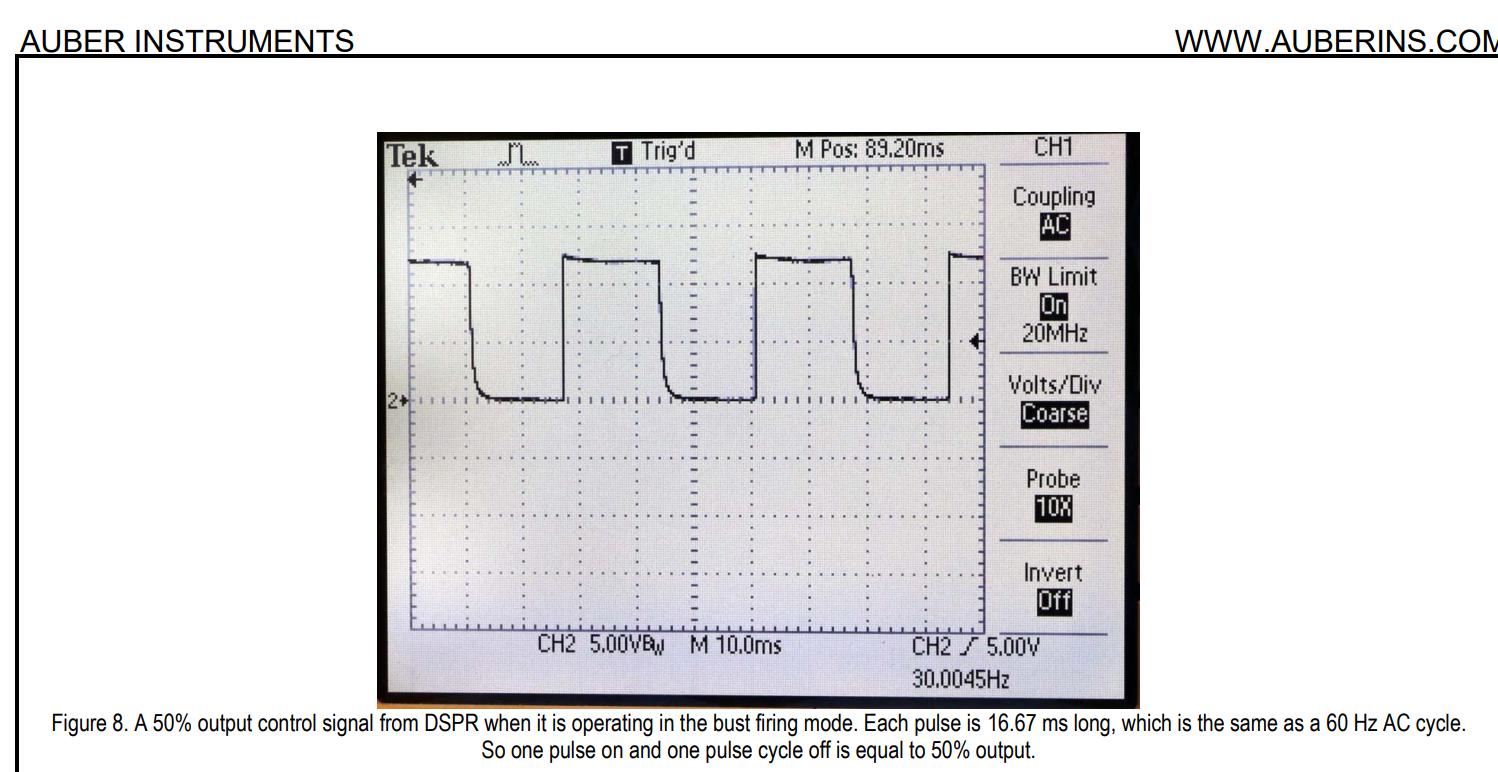

The control of a standard SSR with an Auber DSPR-120 or DSPR-3xx controller is about as fine as you'd ever need. The SSbrewtech animation that is supposed to scare you off a typical PID/SSR is only SOMETIMES accurate. There are PIDs of all different flavors out there and some of them have a minimum cycle time of 2 seconds. That would mean on for 1 second and off for 1 second when you have it set to 50% output. On the other hand, the DSPR series of controllers from Auber do in fact slice up the AC sine wave just like you're describing you want.

All of that is great, but these controllers have more functions built in than any other "PID-like" controller short of the programmable microcomputer based controllers. Long story short, build a controller with the EZBoil and if you don't like it, I'll buy all the parts from you.

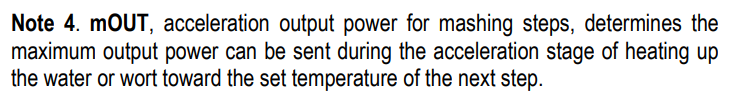

As for fears of scorching, it's possible with all controller technology. If you have a controller in temperature mode (auto or mash mode), and the set point is far away from the actual current temp, they will all fire the element more aggressively to get there as fast as possible. If the temp delta is pretty close, it will fire in very short bursts to get there without overshooting. The DSPR-320 has this parameter you can adjust:

Set it for 25% if you can deal with the slower speed of step ramps.

Or just put a false bottom into the kettle to keep the bag off the element like a sane person and let the controller do its job.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)