You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

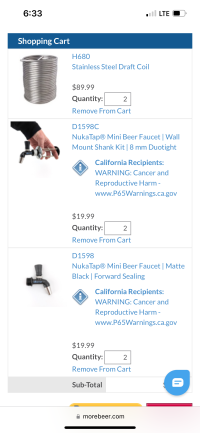

Starting to dream up a jockey box

- Thread starter JohnA

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

JohnA

Well-Known Member

Whoops! Nope. Probably the wrong size MFL on that compression fitting.

I think the point of those is that you can put EVA tubing directly into the back of them. So you need a way to get EVA hooked up to your coil or cold plate.

The heat exchanger is the thing to design around, so I’d figure out that first off.

Edit: aha, I see the coil now. My bad. Carry on.

The heat exchanger is the thing to design around, so I’d figure out that first off.

Edit: aha, I see the coil now. My bad. Carry on.

Last edited:

JohnA

Well-Known Member

Yep, I think that’s my next problem to solve, getting the EVA Barrier tubing hooked up to the coil.

- Joined

- Jan 3, 2020

- Messages

- 3,228

- Reaction score

- 3,910

Use a coil(s) with the same outer diameter as the evabarrier you intend to use. Which in this case is the 8mm (5/16") you intend to use with the Nukatap mini. Connect Evabarrier to coil with ptc coupling. You can just put rubber grommets on the back side (or front, your choice) to act as pass throughs using Evabarrier.

I've built a small 2 tap, coiled, jockey box using the Nukatap minis. Two things about using the minis. 1. They don't require a large beer shank hole but do need 3 small holes for the anchoring screws. 2. The tap handle threads are nonstandard. If you want to change the handles, I know where to get the adapters.

What size coil is that including length? There are less expensive ones than that usually but could be a tariff price jump.

I've built a small 2 tap, coiled, jockey box using the Nukatap minis. Two things about using the minis. 1. They don't require a large beer shank hole but do need 3 small holes for the anchoring screws. 2. The tap handle threads are nonstandard. If you want to change the handles, I know where to get the adapters.

What size coil is that including length? There are less expensive ones than that usually but could be a tariff price jump.

JohnA

Well-Known Member

50' x 3/8"

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

JohnA

Well-Known Member

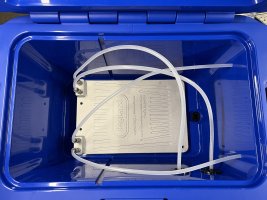

I ended up swapping the coils for the KegLand cold plate with flare ins and outs. Flare to DualTights on those (my first experience) then I’ll just run the EVABarrier straight out a hole or grommet in the cooler. Hmm…I guess I’d better look for a cooler….

- Joined

- Jan 3, 2020

- Messages

- 3,228

- Reaction score

- 3,910

JohnA

Well-Known Member

Very nice! Thanks for the inspiration!

JohnA

Well-Known Member

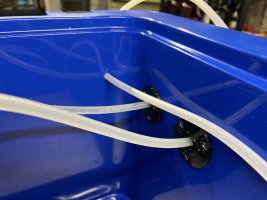

Here’s what I ended up with. When I drilled the four holes through (I guess ten holes including the faucet mounting holes) I found the insulation to be very powdery. Should I seal that somehow? A thin coating of something through the hole, or silicone caulk where the tubing passes in and out (making the tubing immovable)? The 8mm O.D. EVABarrrier I used is too small for the grommets I have. One concern I have is getting insulation inside the tubing when I push it in (it happened during construction).

On the Kegland website they mention possibly adhering the cold plate to the bottom. Any thoughts on that? If I don’t do that, should I consider some feet or something to stand it off the bottom so ice or at least cold water could contact the underside (I have read the cooler is supposed to be constantly drained when using a cold plate)?

Thanks for any insight.

On the Kegland website they mention possibly adhering the cold plate to the bottom. Any thoughts on that? If I don’t do that, should I consider some feet or something to stand it off the bottom so ice or at least cold water could contact the underside (I have read the cooler is supposed to be constantly drained when using a cold plate)?

Thanks for any insight.

Attachments

Way back when I was in High School my buddy made one out of an Igloo cooler. He used copper tubing coiled up, ran the keg line thru the drain hole of the cooler and attached a picnic tap on the other end if I remember right. I don't remember where the CO2 tank was but assume it was outside by the keg. If I remember correctly he used dry ice in the cooler to keep the coil very cold. Again, this was in High School, so there have been many brain cells lost since then. We used to sit by his parents pool and have a blast. The good old days. LOL

Similar threads

- Replies

- 8

- Views

- 508

- Replies

- 21

- Views

- 752