About 6 hours for me. Cleaning and sanitizing take up more time than brewing I think! I hate the cleaning/sanitizing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Start to finish--how long is your typical brew day?

- Thread starter Hex

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

blue77

Well-Known Member

With an AG 5 gal batch it takes me between 5 and 6 hours start to finish. I have tried a few batches while home alone watching my 11 month old son and while nothing went wrong it was far from relaxing.I will only brew now when my wifey is home too. It's true tho. It's not about speed but quality and the fun factor. However, a 8 or 9 hr brew day gets to be a little much.

I here ya...with a wife who usually works nights and two young kids, I have been mostly brewing late at night (Start at 9pm after bed time) or early in the morning, starting around 4am.

superjunior

Well-Known Member

I can brew any style of beer I want. I can easily change the fermentability of my beer with the mash temp.

I still enjoy a quick extract batch, but I love the all grain process. To each their own.

Eric

your right brother and I probably shouldn't of said that. to each their own

EricCSU

Well-Known Member

your right brother and I probably shouldn't of said that. to each their own

No worries. I really love Rye and Marris Otter, so I need all grain to get those flavors. I also love session beers, so if I need to be able to mash high to get the right mouthfeel.

Have you seen the latest BrewingTV episode? Makes me want to brew an extract batch!

Eric

I started at noon today, had all sorts of troubles, did a 75m mash, 90m boil, ended just before 5. So about 5 hours on a "bad" day.

I'm guessing around 4 for a "normal" day. I don't normally keep track because brew-day is always a my-day.

I'm guessing around 4 for a "normal" day. I don't normally keep track because brew-day is always a my-day.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

LakewoodBrew

Well-Known Member

- Joined

- Jul 11, 2009

- Messages

- 5,876

- Reaction score

- 13

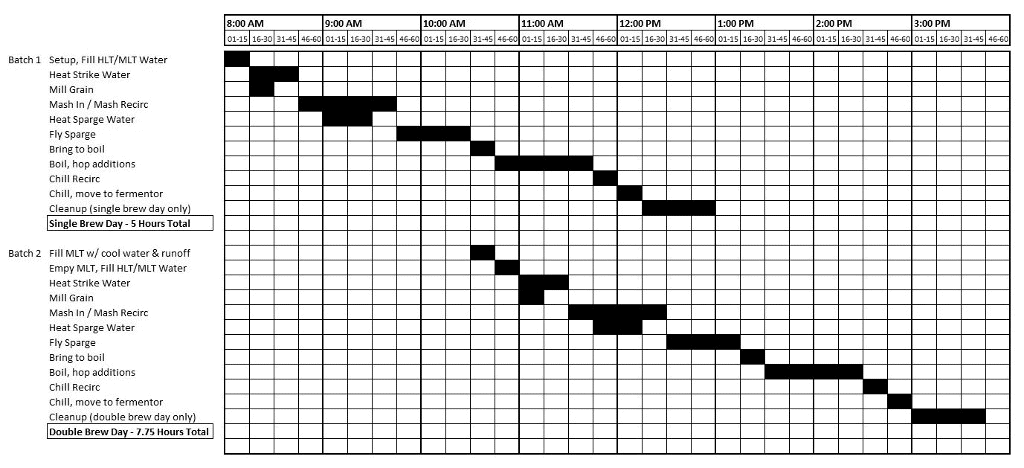

I just built a new rig and in doing so mapped out my brew day process.

Based on 90min mash, 45min sparge, 60 min boil and all the other goodness a single 10 gal batch is 6 hrs. 9 hrs if I do a back to back 20 gal brew day.

Based on 90min mash, 45min sparge, 60 min boil and all the other goodness a single 10 gal batch is 6 hrs. 9 hrs if I do a back to back 20 gal brew day.

DrunkbobSanspants

Well-Known Member

My first brew day was 4 hours soup-to-nuts. (Extract w/steeping grains)

Fantastical

Well-Known Member

5-6 hours.

Hex

Well-Known Member

Thanks for all the great replies, keep 'em coming!

I've done many 3-4 hr extract batches, I did one two weeks ago after having learned all grain. That was fun.

I'm still honing my all grain process, and I did count the rest times in the oven, but did take an hour break for the sac. rest, so my best, actual work time is 7 hrs 15 min, and that was my 4th AG batch.

I did a 20 minute rest at 122, 75 min rest at 155, and 10 min at 170.

I probably could save a half hour if I did single infusion.

Sparge is another hour.

I'd like to get step mashing down to 7 hours.

Stove top is nice because not too much heat to scorch grain, but it's not very quick.

I've done many 3-4 hr extract batches, I did one two weeks ago after having learned all grain. That was fun.

I'm still honing my all grain process, and I did count the rest times in the oven, but did take an hour break for the sac. rest, so my best, actual work time is 7 hrs 15 min, and that was my 4th AG batch.

I did a 20 minute rest at 122, 75 min rest at 155, and 10 min at 170.

I probably could save a half hour if I did single infusion.

Sparge is another hour.

I'd like to get step mashing down to 7 hours.

Stove top is nice because not too much heat to scorch grain, but it's not very quick.

AdamPDX

Active Member

Typically around five hours I would say, though I had an absolutely awful brew day this weekend and it took about eight and a half.

coypoo

Well-Known Member

4 hours start to finish.

Bucket heater is going when I wake up in the morning, so I just roll out of bed and start my mash (usually a little stirring to bring the temp down a few degress b/c the bucket heater works so well). Then a 45 min mash, batch sparge, 60 min boil, immersion chiller, and then clean up. It would probably be less if I had a hose to help clean up, but 4 hours is pretty good, no stress at all.

Bucket heater is going when I wake up in the morning, so I just roll out of bed and start my mash (usually a little stirring to bring the temp down a few degress b/c the bucket heater works so well). Then a 45 min mash, batch sparge, 60 min boil, immersion chiller, and then clean up. It would probably be less if I had a hose to help clean up, but 4 hours is pretty good, no stress at all.

AggieChemDoc

Well-Known Member

5-6 hours, depending on how hard I push it.

2.5G All-Grain took about 6 hours this morning. Started at 7am, finished around 1pm. If I had something better than my stovetop, it would probably cut an hour off that time. Extra time waiting to get started mashing and getting to a boil.

certaut

Well-Known Member

fired up the mlt and hlt at 9 ish, did a 10g batch of ipa and kegged 2-5g batches.

shut the pressure washer off at 2:45

dropped my glasses in the boil kettle at 60 min (they are real clean and have a slight hint of Amarillo

shut the pressure washer off at 2:45

dropped my glasses in the boil kettle at 60 min (they are real clean and have a slight hint of Amarillo

usually 5-6hrs for me on an AG batch.

mb2696

Well-Known Member

start to cleanup my current process is 6 hours, assuming no problems

5.5 hrs for a single 10 gal brewday.

8.5 hrs for a double 10 gal brewday.

I hold pretty close to the graph below.

8.5 hrs for a double 10 gal brewday.

I hold pretty close to the graph below.

Those of you under 7 hrs must have a pretty streamlined setup...either that or I have kids...Oh wait...

GetLooseontheGoose

Well-Known Member

6.5 hours but that is with a 2.5 hr mash in. I need to buy some iodine so i can do a starch test so i can cut that time.

a10t2

Well-Known Member

6.5 hours but that is with a 2.5 hr mash in. I need to buy some iodine so i can do a starch test so i can cut that time.

Just check your pH and temperature. As long as they're both within pretty wide ranges you'll get conversion in a normal amount of time, like 30-60 minutes. Starch testing with iodine isn't all that reliable IME.

What kind of attenuation levels do you get from those mashes?

Rob_B

Well-Known Member

About 5 hours all grain start to finish. I mash for about an hour and batch sparge.

D0ug

Well-Known Member

I stopped by the LHBS yesterday and he had just stocked a new style of kit that could make for about a 1 hour brew day.

He said it was fully prepared wort, just add water to 5 gallons and yeast!

I'm all for the ease and simplicity of extract brewing, but that is a little too simple.

Granted he only had three of them, but still...

He said it was fully prepared wort, just add water to 5 gallons and yeast!

I'm all for the ease and simplicity of extract brewing, but that is a little too simple.

Granted he only had three of them, but still...

GetLooseontheGoose

Well-Known Member

Just check your pH and temperature. As long as they're both within pretty wide ranges you'll get conversion in a normal amount of time, like 30-60 minutes. Starch testing with iodine isn't all that reliable IME.

What kind of attenuation levels do you get from those mashes?

my usual attenuation has been pretty good, above 86%

5-6 hours, depending on how hard I push it.

This. I do 14 gal batches and fly sparge, with pump-assisted CFC and whirlpool. I also save time by getting mash and sparge water out of my tankless hot water heater within 5 degrees of target temp, so I save a lot of time heating those additions from normal temps. If I had a heat stick to help boost my kettle for boiling or a second burner to start heating the kettle while still finishing the sparge I would probably be able to cut another ~30 min off.

ksbrain

Well-Known Member

Those of you under 7 hrs must have a pretty streamlined setup...either that or I have kids...Oh wait...

The kids are the wife's responsibility on brew day.

That's why it's so important to do it quickly!

About 4.5 to 5 hours for me doing AG, batch sparging and a 60 min boil. I've got my system down when but when i first started, and had some problems and my day was around 6 to 7 hours. Now that I've got my routine down, I can can clean or keg while the mash or boil is taking place.

I haven't really gotten comfortable brewing in my new house yet. All my brewing stuff is strewn all over the place and there's lots of little things that seem to take way longer now.

Last weekend my first AG batch in a month or two took something like 6 hours start to finish, maybe longer. Yesterday I did an extract batch and that still took something like 4-5 hours, and that was using a plate chiller so my chilling only took something like 15 minutes. I think part of it is that hauling stuff from the garage all the way to my back yard is an arduous process, and even if I don't forget anything it takes a few trips. And I always forget something. Or two or three things.

I'm doing a witbier next weekend, and I think I will crush the grain on the day before so that I don't spaz out and forget like I did on my last two batches, then have to sit down while my water is at temp and hand crank it through a mill, then reheat the water because it took 10 minutes of cursing to get the grain crushed...

Last weekend my first AG batch in a month or two took something like 6 hours start to finish, maybe longer. Yesterday I did an extract batch and that still took something like 4-5 hours, and that was using a plate chiller so my chilling only took something like 15 minutes. I think part of it is that hauling stuff from the garage all the way to my back yard is an arduous process, and even if I don't forget anything it takes a few trips. And I always forget something. Or two or three things.

I'm doing a witbier next weekend, and I think I will crush the grain on the day before so that I don't spaz out and forget like I did on my last two batches, then have to sit down while my water is at temp and hand crank it through a mill, then reheat the water because it took 10 minutes of cursing to get the grain crushed...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)