drkwoods

Well-Known Member

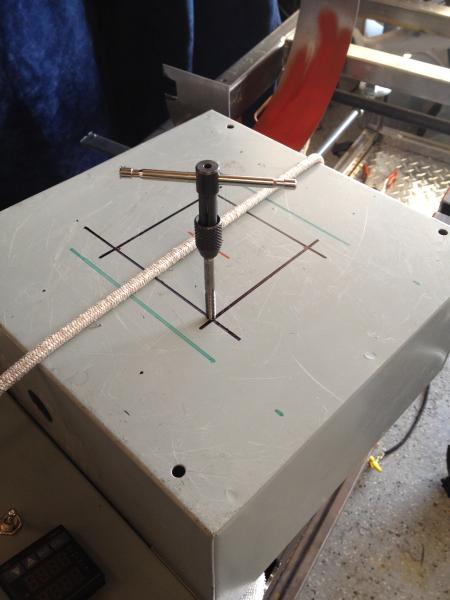

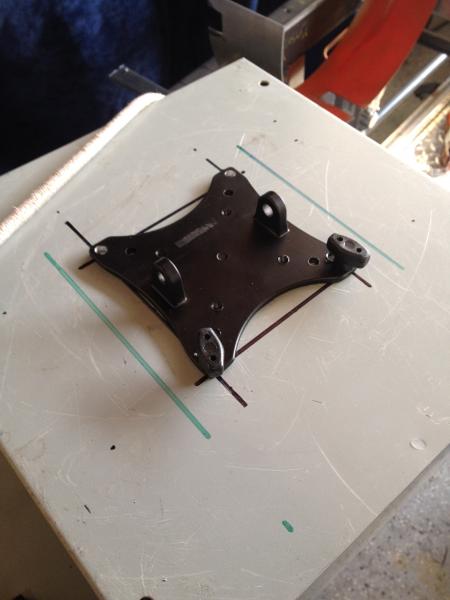

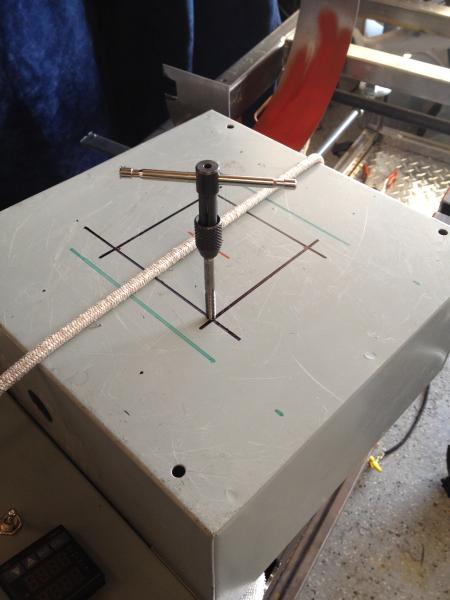

the back side of the Control panel. First I wanted to make a mount and I wanted to use a Flat Panel TV mount. I found a nice adjustable arm that was rated for 33 pounds so I tap'd the back for machine screws and attached the arm to the cart. The back of the panel has the Main power in (Switched) and the two march pumps out (fused). at the bottom I installed and XLR out to plug the Gas Valves into. The three wires in the XLR are as follows. the center pin is the 24v common. The left pin is the TH connection on the gas valve for the BK and the right pin is the TH connection for the HLT gas Valve.. The other three connectors are for the RTD's BK, MASH and HLT

Thanx so much.. Its all ideas I took from here and ran with them, throwing in my own creativity.. I cant wait to brew again.. Ive been idle for 3 months now..

Thanx so much.. Its all ideas I took from here and ran with them, throwing in my own creativity.. I cant wait to brew again.. Ive been idle for 3 months now..

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)