rosienej

Well-Known Member

This thread is to document the build of a Digital Brew Thermometer.

Abstract:

I want a digital thermometer which can stand up to the demands of brewing.

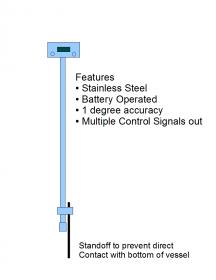

Features:

1) Stainless steel construction

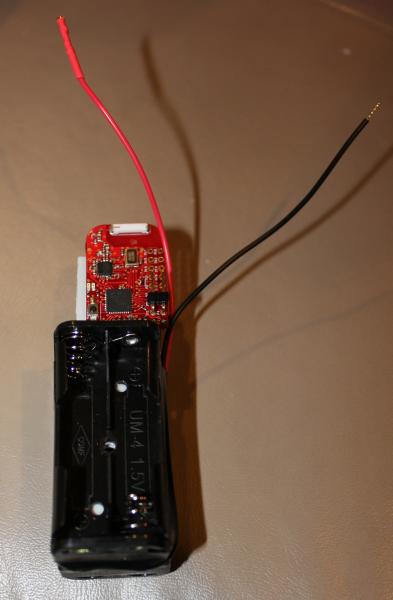

2) Battery powered and self contained.

3) Should be able to output 5 Volt control signals to turn on/off Solid State Relays

4) Alarm output

Current Design.

Mechanical:

1/4 Stainless Steel Cap. (McMaster Carr)

1/4 24 inch stainless steel pipe threaded both ends

Sensor

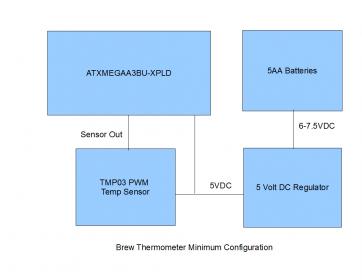

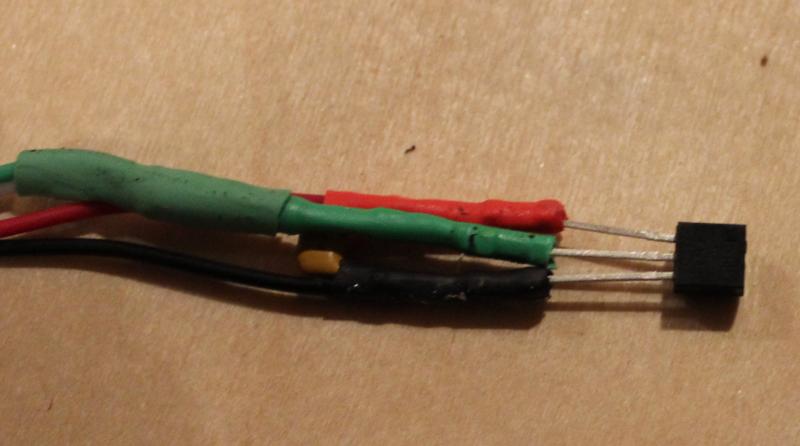

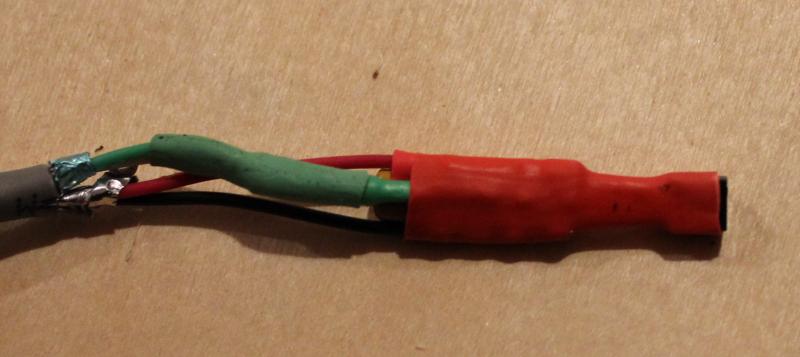

1) Analog Devices TMP03 MEMS based sensor (150 degree C max temp)

Processor+ display

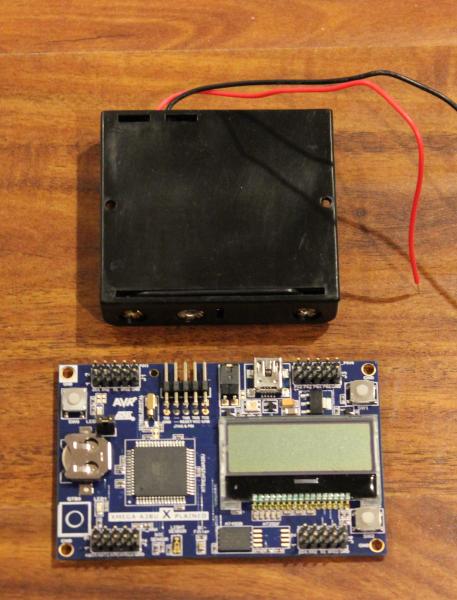

ATXMEGAA3BU-XPLD evaluation board (Mouser has these).

We will provide all of the code open source for non-profit use.

Please suggest features. I figure we need to be able to

1) set some target temps and dwell times,

2) 10 steps....

3) Identify the Action when a target temp is reached (Turn on output 1, set alarm etc...)

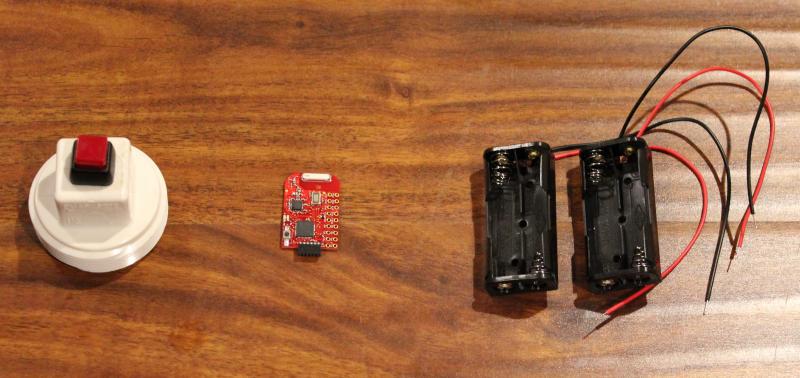

I have the parts coming in, and I have built two of the sensors, I will post pictures...

What do you think?

Joel

Abstract:

I want a digital thermometer which can stand up to the demands of brewing.

Features:

1) Stainless steel construction

2) Battery powered and self contained.

3) Should be able to output 5 Volt control signals to turn on/off Solid State Relays

4) Alarm output

Current Design.

Mechanical:

1/4 Stainless Steel Cap. (McMaster Carr)

1/4 24 inch stainless steel pipe threaded both ends

Sensor

1) Analog Devices TMP03 MEMS based sensor (150 degree C max temp)

Processor+ display

ATXMEGAA3BU-XPLD evaluation board (Mouser has these).

We will provide all of the code open source for non-profit use.

Please suggest features. I figure we need to be able to

1) set some target temps and dwell times,

2) 10 steps....

3) Identify the Action when a target temp is reached (Turn on output 1, set alarm etc...)

I have the parts coming in, and I have built two of the sensors, I will post pictures...

What do you think?

Joel